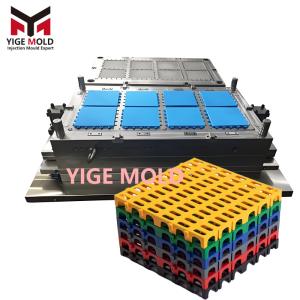

Domestic Garbage Bin Mold

Yige Mold: Your Expert Partner for Premium Household Waste Bin Molds

Yige Mold specializes in the design and manufacturing of high-precision Household Waste Bin Molds. As a trusted partner to global brands, we transform innovative product concepts into reliable, high-volume manufacturing solutions. Our expertise ensures that every trash bin—from simple step-on models to advanced sensor-activated systems—is produced with unmatched quality, efficiency, and durability.

I. Why Choose Yige Mold for Your Bin Molding Projects?

At Yige Mold, we combine engineering excellence with industry-specific knowledge to deliver molds that perform from the first shot to the millionth.

-

Dedicated Expertise: We focus deeply on the household waste bin category, understanding the unique challenges of deep-draw parts, living hinge mechanisms, and user-friendly ergonomics.

-

Full-Service Partnership: Yige Mold manages your project end-to-end, from initial Design for Manufacturability (DFM) analysis and 3D simulation to precision machining, tryout, and after-sales technical support.

-

Technology-Driven Design: We utilize advanced Moldflow analysis to simulate plastic flow, cooling, and warpage, optimizing gate design and cycle time before cutting steel. This reduces development risk and ensures part quality.

-

Built for Durability & Volume: We construct our molds using premium-grade steels (such as H13, S136, 718H) and robust components, engineered for long-term stability in high-volume production environments.

II. Our Capabilities: Precision Molds for Every Bin Type

Yige Mold has the engineering capability and production experience to tackle a wide range of household bin designs:

-

Mechanical Step-On Bins: Precision molds for smooth, reliable pedal and lid linkage systems that withstand repetitive use.

-

Sensor-Activated Smart Bins: Complex molds that integrate housings for infrared sensors, battery compartments, and quiet gear-driven opening mechanisms.

-

Waste Sorting & Multi-Compartment Bins: Molds designed for efficient production of divided bins, ensuring consistent wall thickness and clean partitions.

-

Space-Efficient & Specialty Bins: Expertise in slim-profile, rectangular, or under-counter bin designs that maximize space utility.

III. The Yige Mold Process: Engineered for Success

Our systematic approach ensures on-time delivery of superior molds:

-

Collaborative DFM Review: We work with your team to refine product design, enhancing moldability and functionality while targeting cost savings.

-

Precision Engineering & Simulation: Our engineers design the mold with optimal cooling, ejection, and venting. Moldflow analysis validates the design upfront.

-

State-of-the-Art Manufacturing: We employ a full suite of advanced machinery, including 5-Axis CNC Machining Centers, Fine-Finish EDM, and Precision Wire-Cutting.

-

Comprehensive Tryout & Sampling: Molds are tested in our facility, and pre-production samples are provided for approval, along with detailed process parameters.

IV. The Yige Mold Advantage: Beyond the Tool

Partnering with Yige Mold delivers tangible value to your bottom line and product quality:

-

Faster Time-to-Market: Our experienced project management and parallel workflow processes accelerate development timelines.

-

Optimized Part Cost: Efficient mold designs reduce cycle times and material usage, lowering your cost per unit.

-

Reduced Production Risk: Proven designs and thorough testing minimize downtime and quality issues during your mass production.

-

Long-Term Technical Support: We stand behind our tools with reliable service and maintenance support, ensuring continuous production.