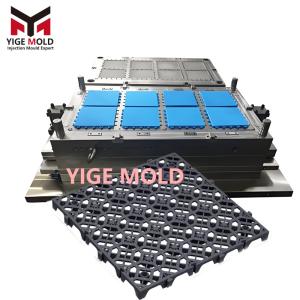

Custom Injection Mold for Plastic Toolbox

Breve descripción:

Custom Injection Mold for Plastic Toolbox—YIGE MOLD delivers quick prototyping & on-time delivery. Custom designs for household/industrial use. Reliable moulds for consistent product quality!...

- Mould Name: Custom Injection Mold for Plastic Toolbox

- Mould Main Material: 718H;P20

- Mould Cavity: 1Cavity

- Delivery Time: 40 working days

Detalles del producto

Etiquetas del producto

Custom Injection Mold for Plastic Toolbox - High-Precision Customized Injection Molding Solutions

H1: Custom Injection Mold for Plastic Toolbox | YIGE MOLD - Precision-Crafted Molds for All Toolbox Production Scenarios

Core Product Advantages

As a professional manufacturer focused on injection mold R&D, YIGE MOLD’s Custom Injection Mold for Plastic Toolbox has become the preferred partner of industrial product manufacturers worldwide, thanks to its precise craftsmanship and flexible customization capabilities.

- Full-Range Customization Compatibility: Supports personalized design of toolbox size, compartment layout and opening-closing structure, perfectly matching production needs from small household toolboxes to heavy-duty industrial tool storage cases.

- High-Durability Material Guarantee: The core is made of high-quality alloy steel and mold steel, reinforced with chromium, nickel and other elements to improve hardness and toughness. It is suitable for injection molding of various toolbox-specific plastics such as ABS, PP and HDPE.

- Efficient Production Empowerment: Optimized mold runner design shortens injection cycle, reduces production waste rate, and features wear resistance and damage resistance to extend service life for mass production.

- Global Standard Compliance: Complies with ISO production specifications, supports OEM/ODM cooperation mode, and can realize the whole process service from design to mass production according to customers’ technical drawings.

Technical Parameters & Customization Scope

Basic Technical Specifications

- Mold Precision: ±0.01mm, ensuring toolbox size consistency and assembly fit

- Applicable Materials: ABS, PP, PC, HDPE, HIPS and other engineering plastics

- Cavity Quantity: 1–8 cavities optional, matched to production capacity needs

- Service Life: Up to 500,000+ injection cycles under standard working conditions

Customization Service Content

- Structural Customization: Functional optimization of compartment division, buckle design, waterproof sealing, folding structure, etc.

- Process Customization: Realization of special processes such as surface texture treatment, two-color injection molding and insert injection molding

- Scenario Compatibility: Household tool storage, industrial equipment supporting, auto repair toolboxes, outdoor portable toolboxes, etc.

- Delivery Supporting: Provide full-process support including 3D design drawing confirmation, sample prototyping and production technical guidance

Why Choose YIGE MOLD’s Custom Injection Molds?

- Origin Advantage Support: Sourced from Taizhou’s mold industry cluster, relying on a mature supply chain to achieve high cost performance and fast delivery, supporting global shipping and professional after-sales response.

- Cost-Effectiveness Optimization: Through precise mold structure design and material selection, YIGE MOLD reduces customers’ comprehensive production and maintenance costs while ensuring quality.

- Full-Process Quality Control: From raw material inspection, mold processing to trial mold verification, strict quality inspection standards are implemented in every link to ensure stable mass production of molds.

- Industry Experience Endorsement: With years of experience serving global industrial manufacturing enterprises, YIGE MOLD has a deep understanding of the market demand and technical standards of toolbox products in different regions, making customized solutions more targeted.

Application Scenarios & Customer Cases

YIGE MOLD’s Custom Injection Mold for Plastic Toolbox has been widely used in multiple fields:

- Industrial Manufacturing: Customized heavy-duty tool storage box molds for machinery processing enterprises, suitable for high-strength storage needs of metal tools

- Automotive Industry: Developed molds for auto repair special toolboxes, realizing classified tool storage and vehicle-mounted compatibility

- Home Furnishing Field: Designed lightweight household toolbox molds, balancing portability and durability to meet daily maintenance tool storage needs

- Outdoor Equipment: Created waterproof and moisture-proof outdoor toolbox molds, suitable for tool protection needs in harsh environments

Contact Us

For customized solutions of Custom Injection Mold for Plastic Toolbox, contact YIGE MOLD now. Our professional team will provide you with one-stop service from design to delivery, helping you seize market opportunities efficiently.

Etiquetas:

Custom Injection Mold for Plastic Toolbox

Escriba su mensaje aquí y envíenoslo