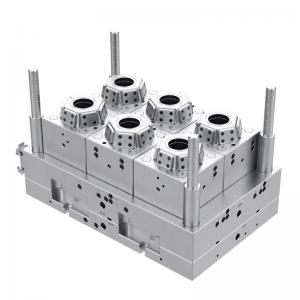

Thin-Wall Container Moulds

Yige Mold: Leading the Way in Custom Thin-Wall Food Container Moulds & IML Solutions in China

YIGE MOLD is a leading professional thin-wall food container mould maker in China, we offer you thin-wall container mould, high speed thin wall mould, multi cavities thin wall mould, IML thin wall mould. With more than 15 years experience of high speed thin wall mould manufacturing, we can make the minimum wall thickness up to 0.3mm in high speed solutions.

What Are Thin-Wall Mould?

A thin-wall mould is a specialized injection mould designed to produce plastic parts with wall thicknesses typically ranging from 0.3mm to 1.5mm—significantly thinner than conventional moulded products. These moulds are engineered to create lightweight, durable, and visually appealing items, such as food containers, trays, lids, and disposable tableware. The manufacturing process demands precision, as even minor design flaws can compromise structural integrity or production speed. Yige Mold’s expertise in this niche ensures that every mould is optimized for both functionality and efficiency, meeting the strictest industry standards.

At Yige Mold, we engineer thin-wall moulds with tolerances as tight as ±0.02mm, ensuring consistent quality even for high-volume production runs of 1,000,000+ units.

The Advantages of Thin-Wall Moulds: Lightweight, Fast, and Sustainable

1. Lightweight Design for Cost and Resource Savings

Thin-wall products are up to 30% lighter than traditional counterparts, reducing material usage and transportation costs. For the food industry, this translates to lower packaging weights, fewer carbon emissions, and enhanced cost-efficiency—all while maintaining structural strength. We custom thin-wall food container injection moulds are designed to maximize wall thickness uniformity, ensuring containers are robust enough for stacking, transportation, and direct food contact.

2. High-Speed Production for Unmatched Efficiency

High-speed thin-wall moulds achieve cycle times under 5 seconds, boosting output by 50% compared to standard moulds. Yige Mold’s proprietary cooling channels cut solidification time by 18%.

3. Improves Product Performance

- Uniform wall thickness prevents warping (verified by Moldflow analysis)

- Smooth surfaces for seamless IML (In-Mold Labeling) integration

4. Lowers Energy Consumption

Fast cycles and optimized clamping force reduce energy use by 25%, as seen in our 32-cavity thin-wall yogurt cup mould for a French dairy brand.

5. Simplifies Stacking & Storage

Thin-wall containers nest compactly, cutting warehouse space needs by 35%.

Yige Mold: Your Partner for Thin-Wall Mould Excellence

With over 15 years of experience, Yige Mold has perfected the art of thin-wall moulding, serving clients in over 30 countries. Here’s why we’re the preferred choice for high speed thin-wall moulds and custom food container solutions, we took three steps to making thin wall mould from rough tooling, half-precision tooling and precision tooling. We have very strictly dimension inspections for each steps. Meanwhile, we adopt S136 stainless steel for thin wall mould core and cavity area, the hardness can reach to HRC 42-48. based on good mould steel and precision tooling guaranteed our high speed thin wall mould life to 3 million shots, this is the most fundamental requirement for making a good thin-wall moulds.

Contact us at quotation@yigemold.com for a complimentary DFM report within 24 hours. Let’s build faster, lighter, and smarter packaging together!