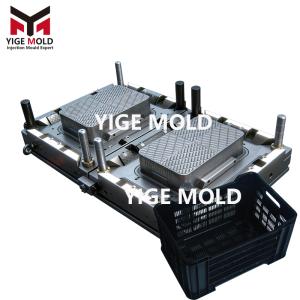

Interlocking Mat Mold

Interlocking Mat Mold - Yige Molds Professional Injection Molding Solution

Interlocking Mat Mold - Yige Molds Professional Injection Molding Solution

I. Core Injection Molding Technology

The interlocking mat mold utilizes advanced injection molding technology, focusing on producing high-precision, high-performance interlocking floor mat products. The injection molding process involves injecting molten plastic under high pressure into a precision mold cavity, followed by cooling and solidification to form products with stable dimensions and consistent structures.

II. Key Points of Injection Molding Process

1. Mold Design Optimization

-

Parting Surface Design: Adopts multi-surface parting structures to ensure smooth demolding of complex interlocking structures

-

Runner System: Optimizes hot runner design to achieve multi-point balanced gate filling and reduce weld lines

-

Ventilation System: Precision vent groove design effectively eliminates cavity gases, preventing bubble defects

2. Injection Parameter Control

-

Injection Pressure: Precisely controls injection pressure within the 80-120MPa range

-

Holding Time: Scientifically sets holding time to ensure complete product filling

-

Cooling Time: Optimizes cooling time according to different product thicknesses to improve production efficiency

III. Mold Manufacturing Process

1. Mold Material Selection

-

Cavity Material: Uses high-hardness mold steels such as 718H and P20

-

Core Components: Moving parts like sliders and lifters select S136 stainless steel

-

Surface Treatment: Cavity surfaces undergo chrome plating or PVD coating treatment

2. Processing Technology

-

CNC Machining: Five-axis machining centers ensure cavity accuracy of ±0.02mm

-

EDM Processing: Precision EDM machining achieves complex curved surface formation

-

Precision Polishing: Mirror polishing treatment achieves surface finish of Ra≤0.8μm

IV. Injection Equipment Configuration

1. Injection Machine Selection

-

Clamping Force: Calculates appropriate clamping force injection machines based on product projected area

-

Injection Volume: Matches product weight to ensure complete melt filling

-

Control System: Equipped with precision computer control systems for accurate parameter control

2. Auxiliary Equipment

-

Drying System: Pre-drying treatment of raw materials to ensure molding quality

-

Temperature Control System: Precise mold temperature control of ±1℃

-

Robotic Arm: Automated part removal system to improve production efficiency

V. Quality Control System

1. Process Control

-

First Article Inspection: Conducts first article dimensional inspection before each production batch

-

Online Monitoring: Real-time monitoring of injection parameters to ensure process stability

-

Regular Calibration: Regular calibration of equipment parameters to guarantee production consistency

2. Finished Product Inspection

-

Dimensional Testing: Full-dimensional inspection using three-coordinate measuring instruments

-

Functional Testing: Interlocking fit testing to ensure usage functionality

-

Appearance Inspection: Visual inspection of surface quality to meet acceptance standards

VI. Yige Molds Service Advantages

1. Technical Expertise

-

Yige Molds possesses 17 years of injection mold manufacturing experience, with professional teams providing customized solutions

-

Uses CAD/CAM software for 3D modeling, combined with Moldflow molding analysis technology to simulate parameters like melt flow, filling pressure, and shrinkage deformation in advance

-

Engineering teams can provide complete mold design solutions within 14 working days based on specific customer requirements

2. Quality Assurance

-

Each mold undergoes strict quality inspection and trial verification, with three-coordinate measurement of grid dimensional tolerances ±0.15mm

-

Mold key components use slow wire EDM machining with accuracy reaching ±0.005mm

-

Mold lifespan exceeds 800,000 cycles, product dimensional tolerances controlled within ±0.1mm

-

Surface finish Ra≤0.08μm ensures stable batch-to-batch product quality

3. After-sales Service

-

Yige Molds provides 24-hour technical support teams to solve various production problems

-

Common spare parts delivered within 48 hours to minimize customer downtime losses

-

Establishes mold asset management platforms allowing customers to view mold usage status, maintenance records, and remaining lifespan predictions online

-

When molds reach service life, recycling and renovation services are provided, restoring mold performance to over 80% by replacing key components and repairing worn parts

4. Cost Advantage

-

Through mass production and optimized processes, provides customers with the most competitive prices

-

Implements a standardized and customized mold development model, establishing a comprehensive mold standard parts library covering mold bases, ejector pins, guide pillars, bushings, etc.

-

Optimized gating system using hot runner technology reduces material waste by 15%-20% compared to traditional cold runners

-

Improved cooling system design using variable frequency pumps to regulate cooling water flow reduces energy consumption by 30%

VII. Yige Molds Production Advantages

1. Efficiency Advantage

-

Through modular hot runner technology and multi-layer cooling structure design, molding cycles are shortened by 25%

-

Daily production capacity reaches 300-800 pieces, significantly improving production efficiency

-

Optimized gating system using hot runner technology reduces material waste by 15%-20% compared to traditional cold runners

-

Improved cooling system design using variable frequency pumps to regulate cooling water flow reduces energy consumption by 30%

2. Quality Advantage

-

Mold lifespan exceeds 800,000 cycles, product dimensional tolerances controlled within ±0.1mm

-

Surface finish Ra≤0.08μm ensures stable batch-to-batch product quality

-

Products feature impact resistance, anti-aging, high load-bearing strength, stretching, compression, tearing resistance, high-temperature tolerance, and other characteristics

3. Cost Advantage

-

Mass production reduces unit costs, mold maintenance costs lowered by 40%

-

Through optimized production processes and supply chain management, provides customers with the most competitive prices

-

Implements a standardized and customized mold development model, establishing a comprehensive mold standard parts library covering mold bases, ejector pins, guide pillars, bushings, etc., reducing mold design and processing time, lowering costs

The injection molding technology of interlocking mat molds, through precision mold design, advanced equipment configuration, and scientific process control, achieves high-quality, high-efficiency production goals. Yige Molds, with 17 years of technical accumulation and rich industry experience, ensures products possess excellent dimensional accuracy, stable mechanical performance, and good appearance quality through professional injection molding processes, providing customers with reliable interlocking mat product solutions.