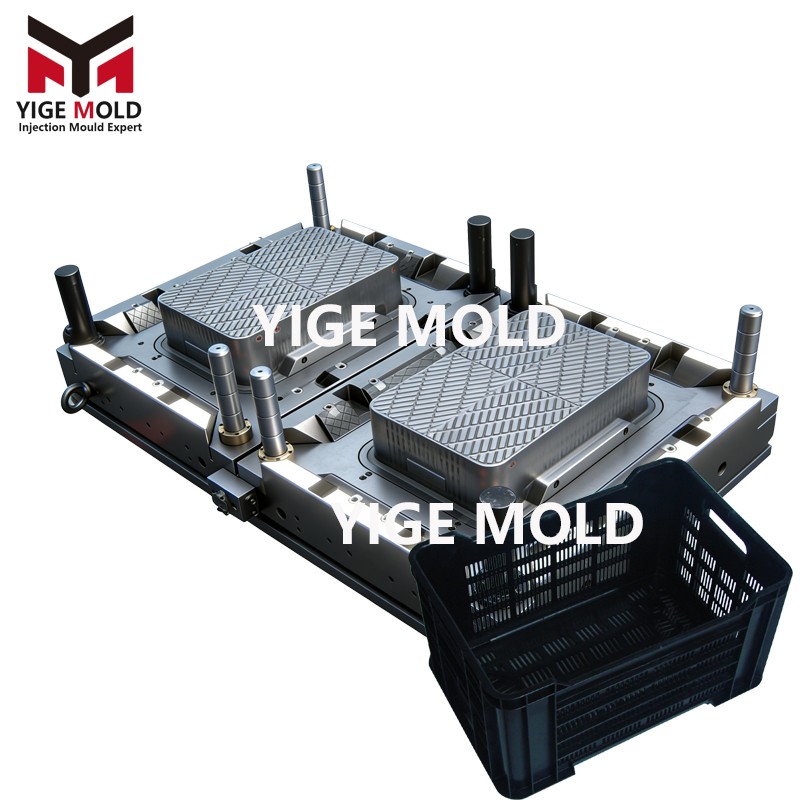

Produce Tote Mold

Agricultural Produce Tote/Carrying Case Mold: Professional Injection Molding Solution

Agricultural Produce Tote/Carrying Case Mold: Professional Injection Molding Solution

I. Product Definition & Market Positioning

The Agricultural Produce Tote/Carrying Case Mold is a professional injection mold used to produce specialized containers for agricultural harvesting, transportation, and storage. Products cover various structures including portable models with handles, stackable turnover types, and ventilated fresh-keeping models, meeting the complete logistics chain needs from field to table. With the scale development of modern agriculture and the upgrade of agricultural cold-chain logistics, requirements for lightweight design, durability, and standardization of carrying cases are continuously increasing.

II. Core Technical Features of the Mold

1. Integrated Handle Design

Yige Mold utilizes integrated handle and box body molding technology. Handle thickness is 1.5-2.0mm with a load-bearing capacity ≥15kg. The handle root employs a reinforced rib structure, and stress concentration areas utilize R-angle transitions ≥2.0mm to ensure a handle bending life ≥10,000 cycles. The handle inner side features anti-slip patterns, improving grip comfort by 30%.

2. Stacking & Nesting Structure

The box bottom includes positioning protrusions and the top features positioning grooves, achieving stacking stability ≥5 layers fully loaded. The nesting structure uses a tapered design (1°-3°) with a nesting ratio ≥60%, saving storage space. The stacking contact surface features anti-slip ribs to prevent shifting during transport.

3. Ventilation & Fresh-Keeping System

Side walls include ventilation hole arrays with an open area ratio of 15%-25% and hole diameters of Φ5-Φ8mm, ensuring air circulation. The bottom includes drainage holes with diameters of Φ3-Φ5mm to prevent water accumulation. Ventilation hole edges undergo rounded corner treatment (R0.5-R1.0) to avoid scratching produce.

4. Lightweight & Strength Balance

Optimized through CAE analysis, the main wall thickness is 1.5-2.0mm, and reinforcing rib thickness is 0.8-1.0mm. Utilizing a 45° cross-reinforced rib layout, bending strength is improved by 35%. Box corners feature a reinforced corner structure, passing drop tests (1.0m height) without cracking.

III. Materials & Process Standards

1. Mold Steel

-

Cavity Materials: S136H, NAK80 pre-hardened mold steel, hardness HRC 38-42

-

Moving Parts: SKD61, H13 hot-work steel, hardness HRC 48-52

-

Surface Treatment: Mirror polishing (Ra ≤ 0.05μm), nitriding (HV ≥ 1000)

2. Product Materials

-

HDPE Material: FDA compliant, temperature resistant from -30℃ to 80℃, excellent impact resistance

-

PP Material: Food-grade certified, temperature resistant from -20℃ to 120℃, suitable for microwave sterilization

-

PP+TPE: Handle uses a hard-soft combination, enhancing grip comfort

3. Injection Molding Process Parameters

-

Barrel Temperature: 180-220℃ for HDPE, 190-230℃ for PP

-

Mold Temperature: 40-80℃, adjusted based on part wall thickness

-

Injection Pressure: 60-120 MPa

-

Holding Pressure: 60-80% of injection pressure

-

Holding Time: Calculated at 1-3 seconds per mm of wall thickness

IV. Product Structural Design Highlights

1. Multi-functional Integrated Design

-

Collapsible Structure: Some products feature hinge structures, reducing volume by 70% when folded

-

Integrated Measuring Scale: Box body includes graduated markings for easy produce weight measurement

-

Non-slip Base: Bottom equipped with TPE non-slip pads, friction coefficient ≥0.8

-

Identification Slot Design: Box body includes reserved slots for labels or laser engraving

2. Ergonomic Detail Design

-

Ergonomic Handle: Handle curvature fits the palm, grip width 40-60mm

-

Easy Opening: Lid designed with opening grooves or protrusions for easy finger operation

-

Anti-Accidental Opening: Snap-fit design includes a secondary locking structure to prevent accidental opening during transport

3. Standardized Design

Box dimensions comply with logistics pallet standards (1200mm×1000mm). Stacking height is uniform, facilitating mechanized handling. Box design includes RFID tag slots, supporting smart logistics management.

V. Quality Control System

1. Dimensional Accuracy Control

-

Primary Dimension Tolerance: ±0.15mm/100mm

-

Fitting Dimension Tolerance: ±0.05mm

-

Flatness: ≤0.3mm/300mm

-

Roundness: ≤0.1mm

2. Performance Testing Standards

-

Load Test: 15kg full load, stacked 5 layers, no deformation after 24 hours

-

Drop Test: Free fall from 1.0m height under full load, no cracking

-

Temperature Resistance Test: -30℃ to 80℃ temperature cycling 10 times, no deformation or cracking

-

Opening/Closing Cycle Life: Handle bending ≥10,000 cycles, no breakage or loosening

3. Food Contact Safety

-

Material Certification: Provides certification reports such as FDA, EU 10/2011, GB 4806.7

-

Heavy Metal Migration: Compliant with GB 31604.1-2015 standard

-

Sensory Test: No abnormal odor, no migrant contamination

VI. Production Efficiency Optimization

1. Quick Mold Change System

-

Standardized Interface: Molds use standard mold bases, mold change time ≤15 minutes

-

Preheating System: Molds preheated to set temperature, reducing heat-up time by 50%

-

Rapid Positioning: Uses locating pins and blocks, positioning accuracy ±0.02mm

2. Automated Production Integration

-

Robot Part Removal: Removal cycle ≤8 seconds, avoiding damage from manual handling

-

Online Inspection: CCD vision inspection system automatically identifies appearance defects

-

Data Acquisition: Real-time production data collection, OEE overall equipment efficiency ≥85%

3. Mold Maintenance

-

Regular Maintenance: Comprehensive maintenance performed every 50,000 cycles

-

Wear Part Warning: Database established for wear part lifespan, enabling advance replacement warning

-

Remote Diagnostics: Supports remote fault diagnosis and technical support

VII. Summary of Professional Manufacturing Points

Successful manufacturing of Agricultural Produce Tote/Carrying Case Molds relies on four core elements:

-

Precision Design: Accurate structural design based on agricultural logistics requirements, ensuring load-bearing performance and durability.

-

Quality Materials: Matching of food-grade raw materials with high-performance mold steels, meeting safety and durability requirements.

-

Advanced Processes: Synergistic action of intelligent temperature control and venting systems, ensuring dimensional stability and surface quality.

-

Strict Quality Control: Full-process quality control from mold machining to product molding, ensuring products meet international standards.