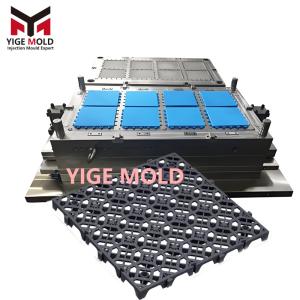

Stacking Stool Mold

Technical Analysis of Stackable Stool Molds: Innovative Design and Efficient Manufacturing Solutions

Technical Analysis of Stackable Stool Molds: Innovative Design and Efficient Manufacturing Solutions

1. Product Definition and Core Value

1.1 Professional Positioning of Stackable Stool Molds

Stackable stool molds are specialized molding tools designed for producing plastic stools that can be vertically stacked for storage. Their core value lies in achieving product stability in stacked conditions, easy separation, and optimized space efficiency through precise structural design. These molds must simultaneously satisfy individual product functionality and multi-product storage optimization requirements.

1.2 Technological Breakthrough Points

-

Stacking Precision Control: Achieves cumulative error ≤0.3mm per layer during multi-layer stacking

-

Separation Force Optimization: One-hand separation force controlled within 8-15N range

-

Structural Lightweighting: Reduces single-piece weight by 15-20% while maintaining 150kg load capacity

-

Rapid Molding: Injection cycle time controlled between 40-60 seconds

2. Core Design Elements of Mold Structure

2.1 Stacking Guidance System Design

Three-Dimensional Guidance Structure

-

Four-column guidance system: Utilizes tapered guide posts (taper 2-3°) with precision-matching guide slots

-

Anti-misalignment design: Asymmetric guidance structure prevents incorrect stacking orientation

-

Self-cleaning function: Guide slots feature chip removal grooves at the bottom to prevent debris accumulation

Stacking Limiting Mechanism

-

Three-stage limiting design: Initial limit, precise positioning, final locking

-

Elastic buffer structure: Silicone cushion pads absorb stacking impact energy

-

Pressure distribution design: Contact area ≥85mm², contact pressure ≤3MPa

2.2 Product Structure Optimization Design

Seat Surface Structure

-

Dual-layer reinforcement rib design: Upper layer radial pattern, lower layer grid pattern

-

Ergonomic curvature: Seat surface curvature radius 800-1200mm

-

Anti-slip texture: Diamond-pattern anti-slip surface with friction coefficient 0.6-0.8

Leg Structure

-

Pyramid stability structure: Four legs inclined at 12-15° angle

-

Internal cavity reinforcement: Triangular internal support structure

-

Footpad integration design: Reserved structure for TPE soft rubber secondary injection

2.3 Innovative Application of Mold Materials

Special Steel Selection

-

Cavity module:P20or718h

-

Guidance components: VIKING wear-resistant alloy steel, hardness HRC 54-58

-

Ejection system: DAC55 hot-work mold steel, hardness HRC 46-50

Surface Treatment Processes

-

Nano-coating technology: DLC coating on cavity surface reduces friction coefficient to 0.1

-

Micro-arc oxidation treatment: Increases guide post surface hardness to HV1200

-

Special texture processing: Anti-slip textures created using laser etching process

3. Precision Manufacturing Process Flow

3.1 High-Precision Machining Solutions

Five-Axis Simultaneous Machining

-

Impeller-type tool path programming: Improves curved surface machining efficiency by 30%

-

Constant load cutting technology: Surface roughness Ra ≤0.2μm

-

Online measurement compensation: Machining accuracy improved to ±0.008mm

Special Machining Processes

-

Deep hole drilling technology: Cooling water channel depth-to-diameter ratio reaches 30:1

-

Micro-EDM machining: Machining accuracy ±0.003mm

-

Ultrasonic-assisted polishing: Surface finish reaches A1 grade

3.2 Inspection and Verification System

Three-Dimensional Digital Inspection

-

Blue light scanning system: Complete dimensional inspection time ≤15 minutes

-

Point cloud data analysis: Automatic comparison of 3000 feature points

-

Virtual assembly verification: Stacking interference check accuracy 0.02mm

Functional Testing Standards

-

Stacking stability test: 20-layer stacking, offset ≤1.5mm

-

Fatigue life test: 10000 stacking-separation cycle tests

-

Environmental adaptability test: -20℃ to 60℃ temperature cycling tests

4. Injection Molding Process Innovation

4.1 Molding Parameter Optimization

Temperature Control Strategy

-

Zoned mold temperature control: 5 independent temperature control zones, temperature difference ≤±0.8℃

-

Dynamic mold temperature technology: Rapid heating to 80℃, cooling to 45℃ after holding pressure

-

Hot runner balance design: 8 hot nozzle temperature uniformity ≤±2℃

Pressure Control Solutions

-

Multi-stage injection control: 6-stage injection speed, precise control of weld line positions

-

Variable pressure holding: 3-stage holding pressure reduction, minimizes shrinkage deformation

-

Closed-loop pressure control: Real-time monitoring and adjustment, pressure fluctuation ≤±0.5MPa

4.2 Quality Control System

Online Monitoring System

-

In-mold pressure sensors: 4-point pressure monitoring with real-time feedback

-

Infrared temperature monitoring: 16-point temperature scanning, temperature distribution visualization

-

Visual inspection system: 100% automatic defect detection

Performance Testing Standards

-

Load capacity test: Static load 150kg for 24 hours, deformation ≤2mm

-

Impact test: Free fall from 1 meter height, no cracks or damage

-

Aging test: UV exposure for 1000 hours, color difference ΔE ≤1.5

5. Production Efficiency Enhancement Solutions

5.1 Intelligent Mold Design

Quick Mold Change System

-

Standardized interfaces: Mold change time ≤8 minutes

-

Automatic positioning device: Repeat positioning accuracy ±0.01mm

-

Integrated water and electrical circuits: Quick-connect coupling time ≤30 seconds

Automation Integration

-

Robotic automatic part removal: Cycle time 3.5 seconds

-

Online runner removal system: Automatic runner separation and recycling

-

Automatic stacking and packaging: Automatic palletizing at production line end

6. Sustainable Development Characteristics

6.1 Eco-Design Philosophy

Material Recyclability

-

Single-material design: Facilitates recycling classification

-

Pollution-free materials: Complies with RoHS, REACH standards

-

Recycled material compatibility: Compatible with up to 30% recycled material usage

Energy Consumption Optimization Design

-

Efficient hot runner system: Reduces heating power by 25%

-

Rapid circulating water channels: Cools cooling time by 30%

-

Energy-saving servo systems: Overall energy consumption reduced by 20%

6.2 Long-Life Design

Wear-Resistant Design

-

Hardened treatment of key components: Extends service life by 3 times

-

Automatic lubrication system: Reduces wear by 80%

-

Corrosion protection treatment: Corrosion-resistant life ≥10 years

Maintainability Design

-

Standardized wearing parts: Replacement time ≤2 hours

-

Optimized maintenance access: Increases maintenance space by 40%

-

Condition monitoring system: Predictive maintenance alerts

7. Quality Control System

7.1 Process Quality Control

Real-Time Monitoring Parameters

-

Injection pressure curve: Deviation from standard curve ≤3%

-

Mold cavity temperature distribution: 32-point temperature monitoring network

-

Product weight monitoring: Weight measurement per shot, deviation ≤±0.5%

Online Inspection Items

-

Automatic dimensional measurement: Laser measurement of critical dimensions

-

Visual defect detection: 100% inspection by machine vision system

-

Functional testing: Automatic stacking separation force testing

7.2 Factory Inspection Standards

Performance Testing Items

-

Stacking stability: 10-layer stacking tilt angle ≤1.5°

-

Separation force test: Consistency ≥95% within 8-15N range

-

Fatigue testing: 5000 stacking cycles without abnormalities

Life Test Verification

-

Accelerated aging test: Equivalent service life of 10 years

-

Environmental adaptability: -30℃ to 70℃ temperature cycling

-

Chemical resistance: Common cleaner immersion tests