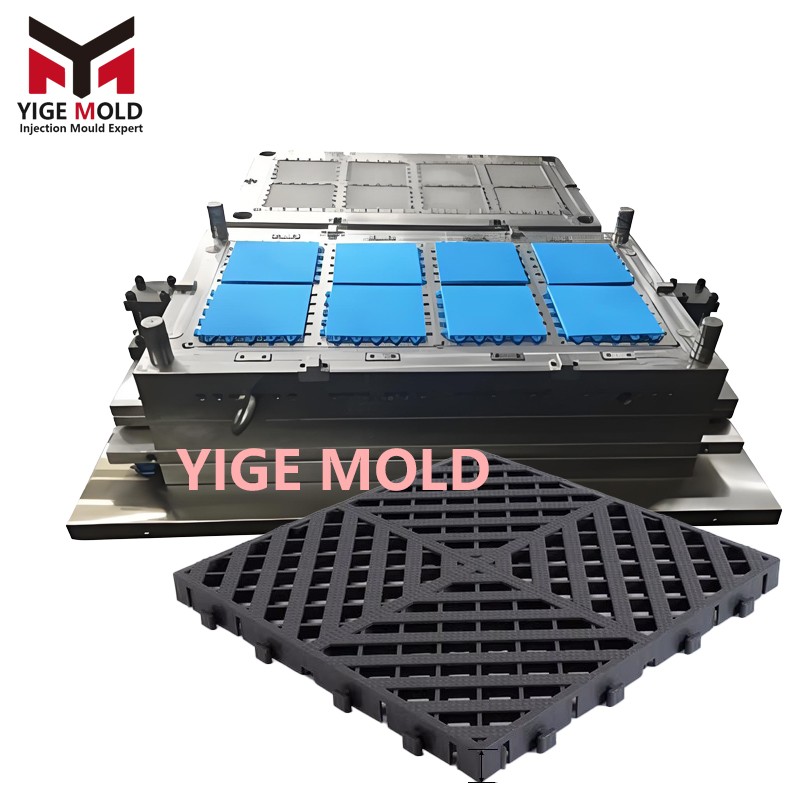

Injection Mold for Plastic Floors

Plastic Floor Injection Mold: The Precision Manufacturing Core of Modern Architectural Decoration

Plastic Floor Injection Mold: The Precision Manufacturing Core of Modern Architectural Decoration

Plastic floor injection molds are specialized equipment that utilize high-precision injection molding technology to produce new types of flooring materials such as SPC stone-plastic floors and WPC wood-plastic floors. These molds use a hot runner system to inject composite materials like PVC, calcium carbonate powder, and wood flour in a single cycle, creating floor products that are structurally stable, load-bearing, and feature realistic surface textures. As essential tools in modern architectural decoration, the design and manufacturing level of plastic floor molds directly determine the product's service life, wear resistance, and installation convenience.

Core Technical Features and Process Advantages

High-Precision Structural Design System

Plastic floor injection molds employ multi-point hot runner technology to ensure uniform filling of the molten material into the cavity, preventing defects such as shrinkage and warping in the product. The mold cavity surface undergoes mirror polishing, achieving a surface smoothness of up to Ra0.8μm, ensuring clear surface textures and realistic tactile qualities for the flooring. The hot runner system enables uniform filling of the molten plastic through precise temperature control and timing. The runner layout is optimized according to the product's structural characteristics to prevent weld lines from occurring in stress-bearing areas, ensuring product structural strength. The main runner is designed with a large diameter to reduce pressure loss and improve injection efficiency, with a single mold capable of producing 2,000–3,000 square meters per day.

Long-Life Design Philosophy

Core mold components are made from high-quality imported mold steels such as 718H, S136, and NAK80. After vacuum heat treatment and cryogenic treatment, the hardness can reach HRC48-52, with a service life exceeding 1 million cycles. 718H mold steel offers excellent polishing performance and wear resistance, making it suitable for main forming parts like cavities and cores. S136 material has superior corrosion resistance, making it ideal for producing transparent or food-grade products. NAK80 material features high hardness and good wear resistance, making it suitable for moving parts such as sliders and lifters. Guide pillars and bushings adopt an oil-free lubrication design, reducing maintenance frequency and lowering operational costs for enterprises.

Efficient Cooling and Venting Systems

The cooling system directly impacts production efficiency and product quality. The mold utilizes a multi-circuit cooling system, with independent cooling channels for the core and cavity to ensure uniform cooling. Cooling channels are designed in a spiral or baffle style to improve cooling efficiency and shorten the molding cycle. The layout of cooling channels avoids moving parts such as ejector pins and sliders to ensure safe mold operation. The venting system includes venting slots at the parting line, core inserts, sliders, and other locations, with slot depth controlled at 0.03–0.05mm and width at 8–10mm, preventing defects such as burning or short shots in the product.

Advanced Processing and Manufacturing Processes

Five-Axis CNC Machining Technology

Mold processing employs advanced equipment such as five-axis CNC milling machines, precision grinders, and slow wire EDM. Main forming parts like cavities and cores are roughed and finished using five-axis machining centers, achieving machining accuracy of ±0.01mm. For complex curved surfaces, high-speed milling technology is used, achieving surface quality of up to Ra0.4μm. Standard parts such as guide pillars, bushings, and ejector pins are processed using precision grinders, with fit clearance controlled within 0.005–0.01mm to ensure smooth movement. Moving parts like sliders and lifters are processed using slow wire EDM, achieving machining accuracy of ±0.003mm.

EDM Precision Machining

For areas difficult to mill, such as deep cavities and narrow slots, electrical discharge machining (EDM) technology is employed. Electrode materials are selected from copper or graphite, and precision machining is performed using EDM forming machines. Discharge parameters are strictly controlled during processing to ensure surface quality. For deep cavity areas, multi-electrode layered processing is used to avoid the impact of electrode wear on machining accuracy. EDM can achieve dimensional accuracy of ±2–3μm, with corner R-values as low as 0.03mm and optimal machining surface roughness below Ra0.3μm. Mirror-like machining effects can be achieved through advanced processing techniques.

Surface Treatment and Polishing Processes

The mold cavity surface undergoes mirror polishing, with the polishing process including multiple stages such as rough polishing, medium polishing, and fine polishing. Rough polishing uses oil stones or sandpaper to remove machining marks; medium polishing uses diamond paste or aluminum oxide polishing paste to improve surface smoothness; fine polishing uses mirror polishing paste to achieve a mirror-like finish. For areas requiring wear resistance, PVD or CVD coating treatments are applied to increase surface hardness and wear resistance. Coating materials can include TiN, TiCN, CrN, etc., with coating thicknesses of 2–4μm and hardness up to HV2000 or higher.

Material Characteristics and Performance Advantages

SPC Stone-Plastic Floor Material Characteristics

SPC stone-plastic floors consist of 25% polyvinyl chloride and 75% calcium carbonate powder. They are rigid sheet flooring with high density and stability. Their shrinkage rate is ≤1‰ (after tempering), with a density of 1.9–2 tons per cubic meter. SPC flooring offers excellent waterproof and moisture-proof properties, does not absorb water, and resists decay or expansion after exposure to moisture. It is insect- and termite-resistant, effectively preventing pest infestations. Its fire resistance rating reaches B1, self-extinguishing in case of fire without emitting toxic gases. It boasts outstanding environmental performance, containing no benzene or formaldehyde, and complies with EN14372, EN649-2011, IEC62321, and GB4085-83 standards.

WPC Wood-Plastic Floor Material Characteristics

WPC wood-plastic floors primarily consist of polyvinyl chloride and wood flour, making them semi-rigid sheet flooring. Early products included wood flour, but some current products no longer contain wood fibers, with the main components being PVC and stone powder. WPC flooring offers excellent waterproof performance, comfortable foot feel similar to solid wood flooring, and outstanding environmental performance. Its abrasion resistance can reach 9,000 revolutions per minute, with thickness generally ranging from 8–9mm. It features a click-lock design for simple installation, requiring no adhesive or underlayment, making it suitable for DIY installation.

LVT Luxury Vinyl Tile

LVT flooring is primarily made of a higher proportion of polyvinyl chloride and a smaller amount of calcium carbonate powder, making it semi-rigid sheet flooring. It is soft, flexible, and can be bent into shape. The thickness generally does not exceed 5mm, with some products as thin as 2–3mm. LVT flooring is environmentally friendly, non-toxic, highly wear-resistant, elastic, and impact-resistant. However, due to its thinness, it may buckle when installed over large areas, requiring a highly level subfloor.

Application Areas and Market Prospects

Home Decoration Applications

Plastic floor injection molds are widely used in residential areas such as living rooms, bedrooms, kitchens, and bathrooms. SPC stone-plastic floors and WPC wood-plastic floors, with their waterproof, slip-resistant, and easy-to-clean characteristics, have become ideal choices for modern home renovation. Product specifications range from 300×300mm to 1200×200mm, with thicknesses from 3mm to 8mm, meeting the needs of different usage scenarios. Products such as wood-grain, stone-grain, and carpet-pattern floors cater to various home decoration styles, providing a comfortable and quiet living environment with their pleasant underfoot feel and soundproofing properties.

Commercial Space Applications

In commercial settings, plastic flooring is widely used in offices, shopping malls, hotels, restaurants, and exhibition halls. SPC flooring's wear resistance, pressure resistance, and aesthetic appeal enhance the overall image of commercial spaces. In educational institutions such as schools, kindergartens, and training centers, its environmental, safety, and comfort features suit environments where students and teachers spend extended periods. In medical facilities like hospitals, clinics, and nursing homes, PVC flooring is easy to clean, helping maintain hygienic environments while providing shock absorption and slip resistance, ensuring a safe and comfortable working environment.

Sports Venues and Industrial Applications

In sports venues such as gyms, dance studios, sports halls, basketball courts, and badminton courts, floors with elasticity and slip resistance are required. Plastic flooring offers excellent shock absorption and rebound properties, reducing the impact of physical activity on joints and muscles. In industrial settings like factories, workshops, and warehouses, PVC flooring is wear-resistant and corrosion-resistant, suitable for high-intensity environments. In public facilities like airports, stations, and libraries, its durability, ease of maintenance, and aesthetic appeal make it ideal for high-traffic public spaces.

Yige Mold's Technical Advantages and Service Philosophy

Yige Mold possesses extensive technical accumulation and manufacturing experience in the field of plastic floor mold manufacturing. Utilizing advanced CAD/CAM design software and equipped with high-end processing equipment such as five-axis CNC milling machines, precision grinders, and EDM machines, the company provides customers with one-stop services from product design to mold manufacturing. The company holds multiple patents in areas such as hot runner systems, cooling systems, and venting systems. Adopting a modular design philosophy, it can quickly customize floor molds of different specifications based on customer requirements, shortening delivery cycles and reducing customer costs.

In terms of quality control, Yige Mold has established a comprehensive quality management system, with strict inspections conducted at every stage from raw material procurement to finished product shipment. The company is equipped with precision inspection equipment such as coordinate measuring machines and video measuring systems to ensure mold accuracy meets design requirements, providing customers with high-quality mold products. Yige Mold consistently adheres to a customer-centric approach, offering comprehensive pre-sales, in-sales, and after-sales services. With a professional technical team, the company provides value-added services such as technical consultation, mold maintenance, and process optimization, helping customers improve production efficiency and reduce operational costs.

Through the comprehensive technical introduction above, it is evident that plastic floor injection molds, as core equipment in modern architectural decoration, directly determine product quality and production efficiency. With continuous technological advancements and growing market demand, the plastic floor mold industry will usher in broader development prospects, providing more high-quality flooring material solutions for green buildings, smart homes, and healthy living environments.