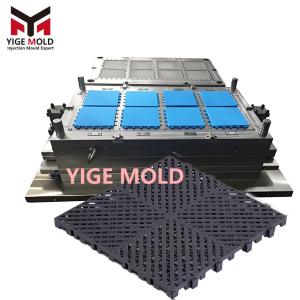

Thick-wall Plastic Planter Mold

Plastic Flower Pot Molds: Core Technology for Garden Container Manufacturing

What is a Plastic Flower Pot Mold?

A plastic flower pot mold is a core tool in the injection molding process, specifically used for producing various types of garden container products. This mold injects molten plastic into precisely designed cavities under high temperature and pressure, which then cools and solidifies to form flower pot products with specific shapes and functions. The quality of the mold directly determines the dimensional accuracy, surface finish, and production efficiency of the final product.

Core Technical Advantages

Advanced Design Concepts

Modern flower pot molds utilize multi-level exhaust systems to effectively avoid defects such as bubbles and short shots. They are equipped with zoned cooling systems to achieve rapid, uniform cooling, shortening the molding cycle. Modular structure designs support quick replacement of mold cores to meet the needs of small-batch, multi-variety production. Special angle designs and ejection mechanisms ensure smooth demolding of complex structures.

Professional Material Selection

The choice of mold steel directly affects service life. P20 pre-hardened plastic mold steel has a hardness of HRC 28-33 and a mold life exceeding 300,000 cycles. 718H mold steel, after quenching and tempering treatment, achieves a hardness of HRC 33-38, with a mold life of over 500,000 cycles. H13 hot work mold steel, after vacuum quenching, exceeds HRC 43 in hardness, with a mold life surpassing 800,000 cycles.

Precision Manufacturing Process

Design Verification Stage

Software such as UG and Pro/E is used for 3D modeling and structural optimization. Mold flow analysis simulations predict filling conditions and potential defects, while structural strength calculations ensure long-term stability of the mold.

Processing and Manufacturing Stage

Five-axis CNC machining centers are employed for precision machining, with slow wire cutting achieving an accuracy of ±0.002mm. Heat treatment processes enhance the mechanical properties of the materials, and the finishing stage achieves final dimensional accuracy. Surface treatments include polishing, plating, and other specialized processes.

Quality Testing Stage

Three-dimensional measuring instruments are used for inspection, with an accuracy of 0.001mm. Continuous production tests verify performance, fatigue strength is assessed, and maintenance cycles are confirmed. Mold life can reach 500,000 to 5 million cycles, with a service life of 5-6 years, extendable to 10 years through maintenance.

Quality Control System

Dimensional Accuracy Control

Critical molding dimensions must meet a tolerance grade of at least IT8, while non-critical dimensions must be at least IT10. Flatness (parting surface, mounting surface) is ≤0.03mm/200mm, and perpendicularity (guide pillar to template) is ≤0.02mm/100mm. The fit clearance between guide pillars and guide bushes is 0.01–0.03mm, and the fit clearance between sliders and slide grooves is ≤0.02mm.

Surface Quality Standards

The roughness of the molding surface is Ra≤0.8μm, with high-gloss products requiring Ra≤0.2μm. Surface defects such as scratches, pores, and sand holes are not allowed. Mirror surface grade evaluation follows the A0-A3 standard, texture consistency is inspected, and flawless surfaces are ensured.

Durability Testing

Continuous production tests (over 100,000 cycles), fatigue strength verification, and maintenance cycle assessments are conducted. Thermogravimetric analysis (TGA) measures material thermal stability, gas chromatography-mass spectrometry (GC-MS) detects volatile organic compounds and plasticizers, and atomic absorption spectrometry (AAS) quantitatively analyzes heavy metal elements.

Application Areas and Expansion

Plastic flower pot molds are widely used in various fields: home gardening accounts for approximately 40% of the market share, commercial decoration accounts for 25%, urban greening projects account for 15%, and professional planting bases account for 20%. Product types include round flower pots, square pots, rectangular pots, hanging pots, vegetable planters, and other styles to meet the display needs of different flowers and plants.

Professional Manufacturing Recommendations

When selecting a mold supplier, key factors to consider include: the professional background and experience of the technical team, the advancement of processing equipment, the completeness of the quality management system, the quality of after-sales service and technical support, and successful case studies and customer reviews. Payment terms typically involve a 50% advance payment, with the balance paid before the qualified mold is shipped. The delivery period is usually 35-60 days.

Conclusion

Plastic flower pot mold manufacturing is a comprehensive field integrating mechanical engineering, materials science, thermodynamics, and control technology. With the development of the gardening industry and technological advancements, mold manufacturing technology will continue to innovate, providing higher quality, more environmentally friendly, and more creative garden container solutions for the market. As a professional mold manufacturer, Yige Mold leverages its strong technical capabilities and innovative strengths to offer comprehensive mold solutions for garden product manufacturers, helping customers enhance market competitiveness and development potential.