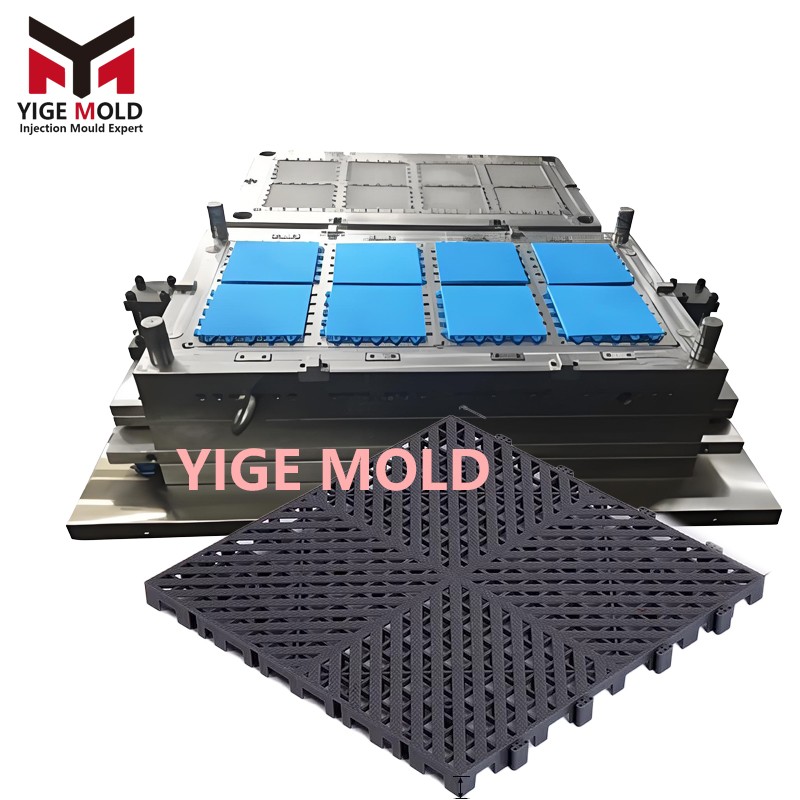

Plastic Floor Grille Mold

The plastic floor grille mold is a specialized engineering system designed to produce the critical interface between a facility's infrastructure and its daily operational demands. Yige Mold approaches this essential manufacturing component as a performance-defining platform, crafting molds that ensure the final product seamlessly integrates structural durability, optimized hydraulic flow, and assured safety in demanding environments from industrial plants to commercial wash bays.

Yige’s engineering process begins with a holistic analysis of the end-use environment. Our design integrates Finite Element Analysis (FEA) to scientifically optimize the grille's rib and deck structure, ensuring maximum load-bearing capacity with minimal material use. Computational fluid dynamics (CFD) informs the aperture geometry and layout, creating efficient, self-cleaning drainage paths. Critically, our proprietary surface texturing technology is engineered directly into the mold cavity, providing a permanently high-traction surface that meets stringent safety standards under wet, oily, or soapy conditions. Built from hardened tool steels with precision-machined components, every Yige mold is constructed for stability, producing parts with consistent dimensional accuracy that enable perfect, gap-free installation.

We specialize in molds for high-performance injection molding, expertly processing reinforced polymers and composites that offer superior chemical resistance and load capacity. Our focus on precision ensures that interlocking features and alignment systems are formed perfectly, facilitating quick, secure, and level installations. The result is a floor system built for long-term reliability.

Choosing Yige Mold is an investment in operational integrity and lifecycle efficiency. We deliver a manufacturing solution that produces floor grilles of exceptional quality and consistency, directly reducing installation time, maintenance costs, and safety risks. By mastering the complex engineering behind the plastic floor grille mold, Yige provides the reliable foundation for safer, more durable, and more efficient facilities.

Yige’s engineering process begins with a holistic analysis of the end-use environment. Our design integrates Finite Element Analysis (FEA) to scientifically optimize the grille's rib and deck structure, ensuring maximum load-bearing capacity with minimal material use. Computational fluid dynamics (CFD) informs the aperture geometry and layout, creating efficient, self-cleaning drainage paths. Critically, our proprietary surface texturing technology is engineered directly into the mold cavity, providing a permanently high-traction surface that meets stringent safety standards under wet, oily, or soapy conditions. Built from hardened tool steels with precision-machined components, every Yige mold is constructed for stability, producing parts with consistent dimensional accuracy that enable perfect, gap-free installation.

We specialize in molds for high-performance injection molding, expertly processing reinforced polymers and composites that offer superior chemical resistance and load capacity. Our focus on precision ensures that interlocking features and alignment systems are formed perfectly, facilitating quick, secure, and level installations. The result is a floor system built for long-term reliability.

Choosing Yige Mold is an investment in operational integrity and lifecycle efficiency. We deliver a manufacturing solution that produces floor grilles of exceptional quality and consistency, directly reducing installation time, maintenance costs, and safety risks. By mastering the complex engineering behind the plastic floor grille mold, Yige provides the reliable foundation for safer, more durable, and more efficient facilities.

Write your message here and send it to us