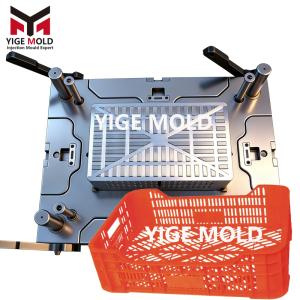

Lid-Mounted Industrial Bin Mold

Technical Specification Manual for Covered Industrial Drum Mold

Technical Specification Manual for Covered Industrial Drum Mold

Chapter 1: Product Definition and Technical Parameters

1.1 Product Overview

Covered industrial drum molds are professionally designed injection molding tools used for manufacturing various types of sealed containers for industrial applications. This type of mold is suitable for producing industrial storage drums with capacities ranging from 30 to 220 liters, widely used for raw material and finished product storage in industries such as chemicals, food, and pharmaceuticals.

1.2 Detailed Technical Specifications

|

Item |

Parameter Range |

Unit |

Notes |

|---|---|---|---|

|

Mold Type |

Hot Runner Injection Mold |

- |

Vertical or horizontal optional |

|

Max. Molded Dimensions |

600×600×800 |

mm |

Length×Width×Height |

|

Mold Weight |

8-15 |

Tons |

Adjusted based on capacity |

|

Mold Opening Stroke |

800-1200 |

mm |

Hydraulically driven |

|

Cooling Time |

60-180 |

Seconds |

Determined by wall thickness |

|

Molding Cycle |

120-300 |

Seconds |

Fully automatic production |

Chapter 2: Mold Structure Design

2.1 Main Structural System

2.1.1 Drum Body Molding Unit

-

Employs a four-plate mold structure, plate thickness ≥250mm

-

Cavity material: NAK80 pre-hardened mold steel, hardness HRC38-42

-

Core material: S136 stainless steel, hardness HRC48-52

-

Guide pins/bushings: SUJ2 bearing steel, surface hardened HRC55-60

2.1.2 Drum Lid Molding System

-

The parting line between lid and body uses a curved transition design

-

Sealing surface angle: 15°±0.5°

-

Latching structure: Three-point locking mechanism, locking force ≥200N

-

Venting system: 8-12 venting slots, depth 0.02-0.03mm

2.2 Sealing Structure Design

2.2.1 Flange Sealing System

-

Flange width: 25±0.2mm

-

Sealing groove depth: 8±0.1mm

-

Seal ring mounting position: Uses R-corner transition, R=1.5mm

-

Flatness requirement: ≤0.15mm/300mm

2.2.2 Lid Locking Mechanism

-

Number of locking points: 3-4 evenly distributed

-

Locking force adjustment range: 150-300N

-

Opening angle: Adjustable 90°-120°

-

Opening cycle life: ≥100,000 cycles

Chapter 3: Gating System Design

3.1 Hot Runner Configuration

System Type: Valve Gate Hot Runner

Number of Hot Nozzles: 4-8

Heating Power: 1500-3000W

Temperature Control Accuracy: ±1°C3.2 Feeding Scheme

-

Main Runner Diameter: Φ16-20mm

-

Branch Runner Diameter: Φ12-15mm

-

Gate Type: Submarine gate

-

Gate Location: Center of drum bottom or side

3.3 Cooling System

-

Cooling Water Hole Diameter: Φ10-12mm

-

Cooling Circuits: 6-8 independent circuits

-

Cooling Uniformity: Temperature difference ≤3°C

-

Cooling Time: Wall thickness × (1.8-2.5) seconds/mm

Chapter 4: Ejection System

4.1 Ejection Mechanism

-

Ejection Method: Combination of hydraulic and mechanical ejection

-

Number of Ejector Pins: 20-40 pins

-

Ejection Stroke: 50-80mm

-

Ejection Speed: Adjustable, 0-500mm/s

4.2 Core Pull Mechanism

-

Number of Side Core Pulls: 4-6 sets

-

Core Pull Stroke: 80-150mm

-

Core Pull Angle: 5°-10°

-

Drive Method: Angled leader pins + hydraulic assist

Chapter 5: Material Selection Standards

5.1 Raw Material Specifications

Main Body Material: High-Density Polyethylene (HDPE)

Grade: HDPE 5000S/5502

Melt Flow Rate: 0.3-0.5g/10min

Density: 0.945-0.955g/cm³

Tensile Strength: ≥24 MPa

Impact Strength: ≥50 kJ/m²5.2 Raw Material Pre-treatment

-

Drying Temperature: 80-85°C

-

Drying Time: 3-4 hours

-

Moisture Content: ≤0.03%

-

Color Masterbatch Addition: 1-2%

Chapter 6: Production Process Parameters

6.1 Injection Molding Parameter Settings

|

Process Stage |

Temperature (°C) |

Pressure (MPa) |

Speed (mm/s) |

Time (s) |

|---|---|---|---|---|

|

Injection |

190-230 |

80-120 |

80-150 |

5-10 |

|

Holding/Packing |

- |

50-80 |

- |

15-30 |

|

Cooling |

20-40 |

- |

- |

60-180 |

|

Mold Opening |

- |

- |

300-500 |

3-5 |

6.2 Molding Process Control

-

Clamping Force: 800-1500 tons

-

Shot Weight: 2000-5000g

-

Back Pressure: 5-15 MPa

-

Screw Speed: 50-80 rpm

Chapter 7: Quality Control Standards

7.1 Dimensional Accuracy Requirements

|

Inspection Item |

Tolerance Requirement |

Measurement Method |

|---|---|---|

|

Diameter Tolerance |

±0.3% |

Three-point measurement method |

|

Height Tolerance |

±0.5mm |

Height gauge |

|

Wall Thickness Uniformity |

≤0.2mm |

Ultrasonic thickness gauge |

|

Sealing Surface Flatness |

≤0.15mm/300mm |

Surface plate measurement |

7.2 Performance Test Items

-

Sealing Test: Fill with water, let stand for 24 hours, no leakage.

-

Drop Test: Drop from 1.2m height under full load, no breakage.

-

Stacking Test: 3-layer stacking under full load for 24 hours, no deformation.

-

Pressure Resistance Test: Hold 0.05 MPa internal pressure for 30 minutes, no abnormalities.

Chapter 8: Mold Maintenance

8.1 Daily Maintenance

Daily Check Items:

1. Lubrication system working status.

2. Hydraulic oil level and oil temperature.

3. Temperature control system accuracy.

4. Wear condition of moving parts.

Weekly Maintenance Items:

1. Clean mold surface dirt.

2. Check venting slot condition.

3. Lubricate all moving parts.

4. Check cooling water channel patency.8.2 Regular Maintenance

-

Every 5,000 cycles: Complete cleaning, inspect seals.

-

Every 10,000 cycles: Measure key dimensions, adjust clearances.

-

Every 50,000 cycles: Replace wear parts, polish cavity.

-

Every 100,000 cycles: Major overhaul, replace all seals.

Chapter 9: Safety Operating Procedures

9.1 Installation Requirements

-

Must check hoisting hole integrity before mold installation.

-

Ensure levelness ≤0.1mm/m during installation.

-

Must perform pressure test before connecting water lines.

-

First mold closing speed must not exceed 30%.

9.2 Operating Procedures

-

Do not inject before mold temperature reaches setpoint.

-

Stop machine immediately and inspect upon unusual noises.

-

Must use dedicated tools for mold cleaning.

-

Non-operators are not allowed in the operating area.

Chapter 10: Troubleshooting Guide

10.1 Common Issue Handling

|

Fault Phenomenon |

Possible Causes |

Solution |

|---|---|---|

|

Flash |

Insufficient clamping force |

Increase clamping force |

|

Short Shot |

Insufficient injection pressure |

Increase injection pressure |

|

Deformation |

Uneven cooling |

Adjust cooling water channels |

|

Surface Defects |

Low mold temperature |

Increase mold temperature |

10.2 Preventive Measures

-

Establish a mold usage record file.

-

Perform regular preventive maintenance.

-

Provide regular training for operators.

-

Manage spare parts inventory.

Technical Consultation & Service

For further details on the technical parameters of covered industrial drum molds or for customized service, please contact our technical team. We provide full-process technical support from mold design to production debugging, ensuring your production needs are best met.