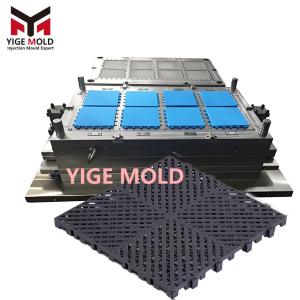

Vegetable basket injection mold

Introduction to Injection Molding Technology for Vegetable Basket Mold of Yige Mold Company

Yige Mold, as a professional injection mold manufacturer, has mature technical solutions in the field of vegetable basket molds. The company uses high-strength mold steel and combines precise processing techniques to ensure that the produced vegetable baskets have stable structures and precise dimensions.

Mold structure features

Yige Mold adopts an advanced hot runner system, which effectively reduces waste production and improves injection molding efficiency. The mold design focuses on smooth demolding, and is equipped with optimized inclined pins and sliders to ensure the smooth demolding of complex grid structures. For the basket stack slot design, Yige Mold ensures molding accuracy through precise processing to ensure the stability of basket stacking.

Production process advantages

The injection molding technology of Yige Mold enables the one-time molding of the basket body, significantly improving production efficiency. Through scientific design of the runner and optimization of the cooling system, the thickness of the basket wall is uniform and the overall strength is excellent. The mold life can exceed one million cycles and is suitable for large-scale production needs. Yige Mold also offers flexible specification adjustment solutions, allowing for quick switching between the production of different capacity vegetable baskets.

Application value

The vegetable baskets produced by Yige Mold are characterized by light weight, corrosion resistance and easy cleaning. They are widely used in agricultural product logistics, supermarket display and other scenarios. Yige Mold attaches great importance to energy-saving and environmentally friendly design. By optimizing the mold structure, it reduces raw material consumption and improves product economy.