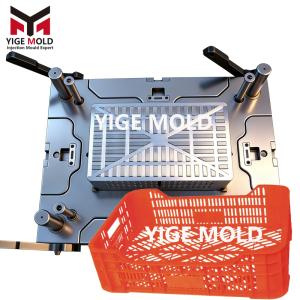

Component box mold

Component Box Mold: The Precision Cornerstone of Industrial Organization Efficiency

Component Box Mold: The Precision Cornerstone of Industrial Organization Efficiency

I. Product Definition and Core Value

A component box mold is a specialized forming tool used to manufacture various storage containers for components. Its products are widely applied in manufacturing, automotive repair, electronic assembly, laboratories, and home tool management. As a crucial carrier for lean production and 5S workplace organization, component boxes serve not only basic storage functions but are also key tools for enhancing work efficiency, ensuring material accuracy, and optimizing space utilization. An excellent component box mold must precisely balance multiple objectives—functionality, durability, spatial efficiency, and cost control—making its technical complexity far exceed that of ordinary container molds.

II. Engineering Challenges in Mold Design

1. Modular Structural Design

Modern component boxes commonly feature stacking and interlocking designs for efficient space utilization. The mold must precisely form the stacking grooves on the top of the box and the anti-slip feet on the bottom, ensuring stability and easy separation when stacked in multiple layers. Side walls typically incorporate handle holes and label slots. The mold requires sliders or lifters to form these lateral features, ensuring smooth, burr-free surfaces. For systems requiring snap-fit connections, the mold must tightly control the fit tolerance (typically within ±0.1mm) between the snap hooks and grooves to ensure secure attachment and smooth disassembly.

2. Balancing Thin Walls and High Strength

To reduce material costs and shipping weight, component boxes generally employ thin-wall design (wall thickness 1.2-2.0mm). The mold must compensate for rigidity through scientifically designed rib patterns (e.g., grid or radial ribs). Rib thickness is typically 50%-60% of the main wall thickness, with fillets at the roots to avoid stress concentration. Corners utilize a graduated thickening design to ensure load-bearing strength while preventing sink marks. The mold cooling system must be optimized for thin walls, employing a multi-point balanced cooling scheme to control temperature variation within 5°C.

3. Forming Internal Partition Systems

Professional component boxes often include adjustable partitions, posing specific demands on the mold:

-

Guide Rail Groove Formation: The inner box walls require precise formation of T-slot or dovetail grooves with consistent width and high parallelism, demanding extremely high machining accuracy and polishing of the mold.

-

Partition Mold: A separate mold system is needed to ensure partition flatness and dimensional consistency, often employing double-sided polishing to achieve surface roughness below Ra 0.8μm.

-

Interfacing Accuracy: A fit clearance of 0.2-0.3mm must be maintained between the box guide rails and partitions, requiring strict dimensional coordination between multiple mold sets.

III. Key Technological Innovations

1. Precision Stacking System Molding Technology

Using parametric design methods to establish a mathematical model for the stacking angle. When the stacking angle is set between 8-12°, it ensures both stable stacking and easy separation. The mold employs multi-stage lifter mechanisms to achieve damage-free separation of undercut structures during ejection. Pre-loaded ejection mechanisms are installed at snap-fit areas to prevent deformation from forced demolding.

2. Anti-Warpage Structural Design

Addressing warpage issues common in large flat bottom areas, the mold incorporates these solutions:

-

Corrugated Bottom Design: Improves bending stiffness through curved structures, with the mold using 5-axis machining to ensure surface accuracy.

-

Gradual Rib Layout: Dense ribbing (15-20mm spacing) in the central bottom area, transitioning gradually to a sparser layout towards the edges.

-

Asymmetric Cooling Solution: Employs differentiated cooling channels for areas of varying wall thickness, controlling differential molding shrinkage within 0.3%.

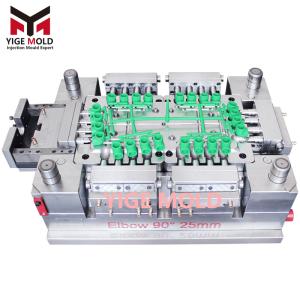

3. Multi-Cavity High-Efficiency Production System

To meet high-volume production demands, molds typically use 1x4, 1x8, or even higher cavity layouts. Runner layouts are optimized through mold flow analysis, using H-type or radial runner systems to ensure fill time differences between cavities are less than 0.15 seconds. Hot runner systems combined with sequential valve gate control enable precise fill control for each zone.

IV. Material Compatibility and Surface Treatment

1. Multi-Material Compatible Design

Common materials for component boxes include PP, ABS, PC/ABS, etc. The mold must be adapted to different material properties:

-

PP Material: Higher shrinkage (1.6-2.0%), requiring increased draft angles (above 1.5°).

-

ABS Material: Requires higher mold temperatures (60-80°C) to ensure surface gloss.

-

Anti-Static Materials: Special surface treatment of the mold is needed to prevent material sticking.

2. Functional Surface Treatment

-

Anti-Slip Texture: Diamond or grid patterns 0.3-0.5mm deep on the bottom, achieved via etching.

-

Identification Areas: Mirror-polished zones for labels or screen printing, with surface roughness Ra ≤ 0.1μm.

-

Scratch-Resistant Treatment: Fine spark erosion textures (VDI 18-22) in high-wear areas to improve durability.

V. Manufacturing Precision Control

1. Dimensional Accuracy Assurance

-

Uses pre-hardened mold steels (P20, 718, etc.) for long-term stability.

-

Key fitting areas employ insert structures for easier maintenance and replacement.

-

CMM inspection ensures main dimensional tolerances within ±0.05mm.

-

Cavities use mirror EDM finishing to achieve surface roughness of Ra 0.4μm.

2. Assembly Testing Standards

-

Stacking Test: 10-layer stacking under full load for 24 hours shows no deformation.

-

Drop Test: No cracking after 6 drops from 1.2-meter height.

-

Environmental Test: Dimensional change rate ≤ 0.3% after temperature cycling from -20°C to 70°C.

-

Life Cycle Test: Snap-fit functions normally after 5000 open/close cycles.

VI. Production Optimization Solutions

1. Quick Mold Change System

The mold features standardized interfaces for quick connection to different tonnage injection molding machines. Standardized designs like locating rings and side locks enable complete mold changeovers within 30 minutes. Cooling circuits use quick-disconnect couplings to reduce setup time.

2. Automation Compatibility

Mold design considers requirements for automated part removal:

-

Standardized robot gripper locations.

-

Ejection system synchronized with robot signals.

-

Design for automatic part drop to avoid manual intervention.

3. Maintenance-Friendly Design

-

Wear parts use standardized specifications.

-

Dedicated cleaning access for venting systems.

-

Zoned cooling circuit control for easier troubleshooting.

VII. Industry Application Expansion

1. Anti-Static Series

Molds incorporate additional surface conductive treatment processes to produce component boxes with volume resistivity of 10^6-10^9 Ω, used for electronic component storage.

2. Chemical-Resistant Series

Using special steels and surface coatings to produce industrial-grade component boxes resistant to chemicals like engine oil and cutting fluid.

3. Transparent Series

Optimizing mold venting and temperature control systems to produce high-clarity component boxes, enabling visual content management.

4. Heavy-Duty Series

Reinforced rib design and wall thickness optimization to produce heavy-duty component boxes with load capacities up to 50kg, meeting tool and mold storage needs.

VIII. Economic Benefit Analysis

Optimally designed component box molds bring significant benefits to manufacturers:

-

Material utilization increases above 95%, saving 8-12% raw material per thousand pieces through wall thickness optimization.

-

Production cycle shortens by 15-20%, with increased output from improved cooling efficiency.

-

Mold life extends to 800,000 - 1,000,000 cycles, reducing maintenance frequency by 40%.

-

Product defect rate controlled below 0.5%, lowering quality costs.

As the foundational manufacturing equipment for industrial organization systems, the technical level of component box molds directly impacts the material management efficiency of modern manufacturing enterprises. From simple storage containers to intelligent material management units, continuous innovation in mold technology is redefining the product value of component boxes. Excellent mold design must consider not only the molding process but also a deep understanding of the usage scenarios, maximizing functionality within cost constraints. This requires mold engineers to possess cross-disciplinary systems thinking and continuous technological innovation capabilities.