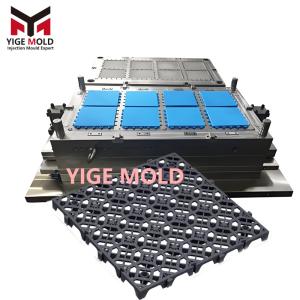

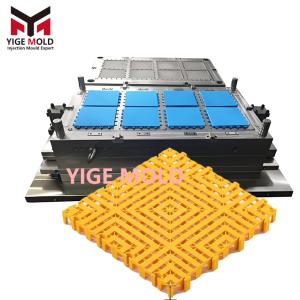

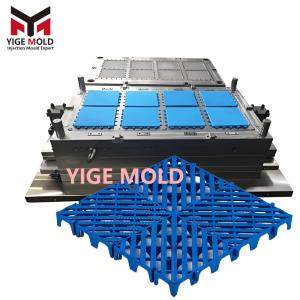

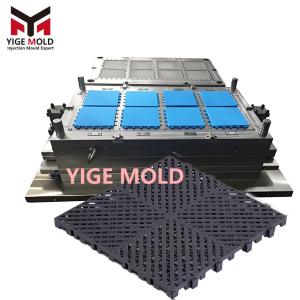

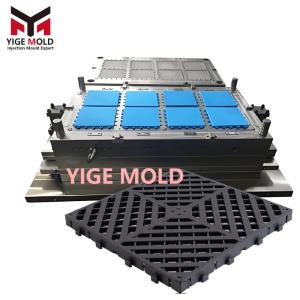

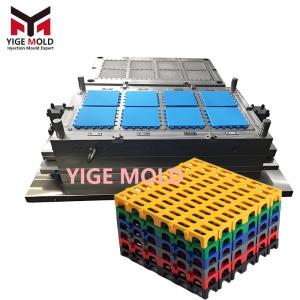

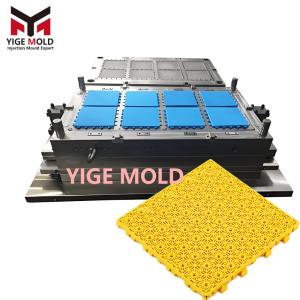

Floor Tile Mold

Precision-Engineered Flooring Molds: YIGE MOLD, Your Heavy-Duty Stadium & Industrial Matting Partner

The foundation of any high-performance commercial flooring system isn't the tile you see—it's the precision tooling you don't. For over a decade, YIGE MOLD has partnered with leading facility operators and manufacturers, engineering the robust plastic stadium floor tile molds and heavy-duty matting molds that define durability underfoot. We operate on a simple principle: standard solutions breed standard problems. That’s why every project begins with a blank slate, focused on delivering a truly custom plastic floor grid mold solution engineered for your exact load, traffic, and environmental demands—not an off-the-shelf compromise.

Our reputation as a trusted car wash floor mat mold supplier and sports flooring specialist is built on solving two core industry challenges: premature mold wear and inconsistent part quality. While many offer molds, we deliver engineered systems. Each heavy-duty plastic stadium floor tile mold is designed for a minimum of 2.5 million cycles using grade-specific steels, with targeted hardening on high-wear components. This isn't just about longevity; it's about guaranteeing that the 100,000th tile produced has the same dimensional accuracy and surface finish as the first, ensuring seamless interlock and reliable performance in demanding environments from arena concourses to industrial work bays.

The YIGE MOLD Difference: Where Engineering Meets Application

Choosing a custom plastic floor grid mold partner is a technical decision. Our engineers bridge the gap between your functional requirements and production reality through application-specific design:

For Stadiums & High-Traffic Areas: We design plastic stadium floor tile molds with patented venting systems that eliminate sink marks on large surface areas, ensuring consistent color and strength. Our lug and interlock profiles are simulation-tested to withstand lateral forces from crowds and equipment, preventing separation under load.

For Car Wash & Industrial Facilities: As a car wash floor mat mold supplier, our focus is on chemical resistance and drainage efficiency. We engineer molds for dual-material injection (combining rigid and flexible polymers) for anti-fatigue mats and design drainage channels with specific draft angles to ensure clean, consistent demolding of complex geometries, preventing clogging and maintaining flow rate.

For Modular & Utility Grids: Our custom plastic floor grid mold capabilities include conformal cooling channel design. This technology allows for uniform cooling within thick grid walls, drastically reducing cycle times by up to 20% and preventing warpage, a critical factor for large-format, interlocking tiles used in ground stabilization.

From Concept to Production: Our Collaborative, Transparent Process

We function as an extension of your team, with a process built on transparency and iteration:

Technical Scoping & DFM Audit: We analyze your part design, not just for function, but for manufacturability. Our initial report often identifies opportunities to reduce weight by 5-10% or enhance strength through rib design without increasing material cost—value engineering that starts on day one.

Advanced Flow & Cooling Simulation: Before any steel is cut, we digitally prototype the mold. Our simulation software models plastic flow, pressure, and cooling to predict and eliminate potential defects like air traps or weld lines, de-risking the project upfront.

Precision Machining & In-Process QC: Core components are machined in our climate-controlled workshop. We implement a layered inspection protocol, verifying critical dimensions at the roughing, semi-finishing, and finishing stages against the original CAD model.

Sampling & Tiered Approval: We don’t just send samples; we host a virtual or in-person T1 sample review. We provide a detailed process report with each sample batch, documenting parameters and measurements, empowering you with data for informed approval.

Production Launch & Sustained Support: Upon shipment, you receive a comprehensive mold passport—a digital dossier with maintenance schedules, spare part lists, and optimal process settings. Our support doesn’t end at delivery.

Your Next Step: Engineer a Superior Flooring Product

In a market where product failure means facility downtime, your mold is your most critical capital investment. Partnering with YIGE MOLD means investing in engineered certainty, from the first tile to the last.

Move beyond generic suppliers. Let's engineer your solution.

Submit your tile or grid design for a confidential DFM and value-engineering analysis. Contact the YIGE MOLD engineering team today to start the conversation.

-

Plastic Floor Mold

-

Anti-slip Plastic Floor Mold

-

Interlocking Mat Mold

-

Industrial Plastic Floor Mold

-

Injection Mold for Plastic Floors

-

Plastic Floor Tile Mold

-

Platform Grating Mold

-

Plastic Floor Grille Mold

-

Injection Mold for Plastic Grilles

-

Plastic Grating Mold

-

Plastic Grid Mold

-

Plastic Grille Mold

-

Mold for Car Wash Grilles

-

Heavy-duty Plastic Grating Floor Mold

-

Automotive Wash Bay Grating Mold

-

PVC Flooring Mold

-

Resilient Flooring Mold