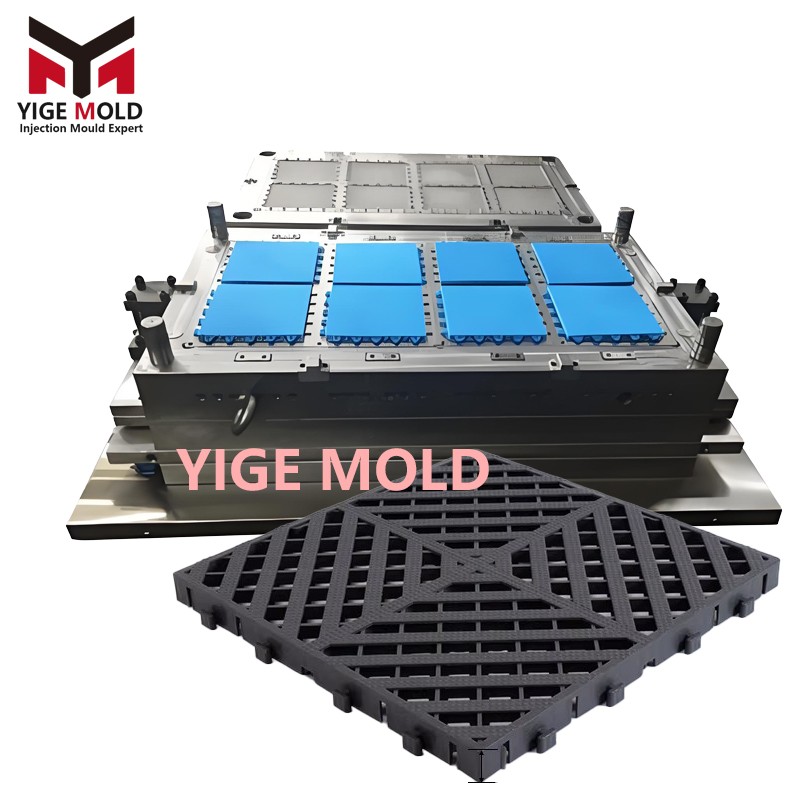

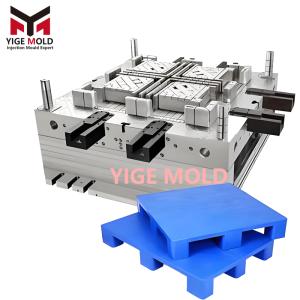

Injection Mold for Plastic Grilles

Yige Mold: Engineering Precision for High-Performance Plastic Grilles

The injection mold for plastic grilles serves as the foundational engineering interface between raw polymer and a finished component that must meet precise structural, functional, and aesthetic demands. Yige Mold approaches this manufacturing critical point as a system-level engineering challenge, creating molds that are not merely shaping tools, but precision instruments designed to ensure part consistency, longevity, and performance in the most demanding applications, from automotive fronts to specialized filtration units.

Yige's engineering process begins with a deep analysis of the grille's end-use environment. Our design philosophy integrates Advanced Flow Simulation and Structural Finite Element Analysis (FEA) to pre-emptively solve the core challenges of molding intricate lattice structures. We optimize gate design and runner systems to achieve perfect flow front advancement, eliminating weld lines and ensuring uniform density in thin ribs. Our proprietary Multi-Zone Temperature Control technology within the mold stabilizes the cooling process, preventing warpage and securing dimensional stability for parts that must fit seamlessly into assemblies. Mold cavities are machined with micron-level precision and often treated with specialized surface coatings to enhance flow release and extend tool life dramatically.

We excel in molding complex, high-aspect-ratio grille designs from a wide spectrum of materials, including glass-filled composites and high-temperature resins. Our molds are built for the rigors of high-volume production, ensuring that every unit—from the first to the millionth—maintains identical tolerances and surface quality. The result is a grille that performs consistently, whether its function is directing airflow, providing protection, or defining a brand's visual identity.

Choosing Yige Mold is an investment in manufacturing reliability and product excellence. We deliver a mold system engineered for optimal cycle times, minimal maintenance, and flawless part quality, effectively reducing the total cost of ownership. By mastering the science behind the plastic grille mold, Yige enables manufacturers to produce components that are not just parts, but reliable, high-performance assets integral to the success of the final product.