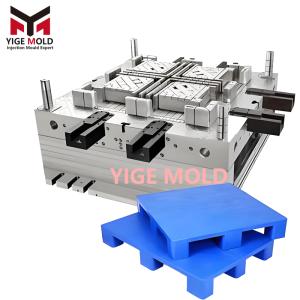

Industrial Pallet Mould

Nowadays, Plastic pallets are revolutionizing logistics and warehousing, offering durability, hygiene, and cost efficiency compared to traditional wooden pallet alternatives. As a leading plastic pallet mould manufacturer, Taizhou Yige Mold Co., Ltd with optimal plastic pallet mould design and competitive pricing to deliver molds that meet global industrial standards.

As we know, plastic pallet production will common mix in a high proportion of recycled plastic raw material, so we designed the pallet mould adopt with valve gate hot runner system, the special filter system design which allow the recycled material injection moulding, this helped customer save much cost and keep the molding running soomthly. In the meantime, we designed the optimal injection & cooling system, approached the mould high speed injection to expand production. Yige pallet mould can pass the drop test, loading test and all the chemical solutions for industrial pallet standard requirements, Yige Mold offer the best pallet molding solutions.

Below is a structured overview of key parameters for plastic pallet molds for reference:

|

Parameter |

Details |

Applications |

|

Material |

High-Density Polyethylene (HDPE) / Polypropylene (PP) |

Heavy-duty logistics, food-grade storage |

|

Mold Cavity |

1-4 cavities (customizable for batch production efficiency) |

Bulk orders, multi-size pallet series |

|

Mold Lifespan |

500,000–1,000,000 shots (depending on maintenance & material quality) |

Long-term industrial use |

|

Clamping Force |

800–2,500 tons (adaptable to pallet size and wall thickness) |

Large-format pallets (1200x1000mm+) |

|

Surface Finish |

Textured or smooth (anti-slip patterns, EDM/etching options) |

Pharma, food industries, outdoor storage |

|

Weight Capacity |

1,000–5,000 kg (static load) / 500–2,000 kg (dynamic load) |

Automotive, construction, warehousing |

|

Cooling Time |

25–60 seconds (optimized for cycle time reduction) |

High-volume manufacturing |

|

Certifications |

ISO 9001, CE, FDA (for food-contact applications) |

Global export compliance |

Material Advantages

HDPE: Resists chemicals, moisture, and UV degradation. Ideal for outdoor pallets.

PP: Lighter weight with high impact strength, suited for nestable designs.

Customization Flexibility

Adjust cavity numbers and clamping force to align with production scales (e.g., 4-cavity molds for 10,000+ units/month).

Durability Metrics

Molds with hardened steel cores (e.g., 718H/NAK80 steel) extend lifespan beyond 800,000 shots.

Eco-Friendly Compliance

Offer recycled HDPE/PP molds (30–50% recycled content) to meet EU/NA sustainability regulations.

With over 15 years of industry leadership, Taizhou Yige Mold Co., Ltd is a trusted plastic pallet mould manufacturer serving clients in 40+ countries. Our portfolio includes molds for:

Logistics Pallets: Nestable, rackable, and four-way entry designs.

Hygienic Pallets: Smooth surfaces for food and pharmaceutical sectors.

Heavy-Duty Pallets: Reinforced structures for automotive and construction industries.

If you need custom plastic pallet mold design for specialized applications or scalable pallet molding solutions, our expertise ensures seamless integration into your supply chain. Get a quote now!