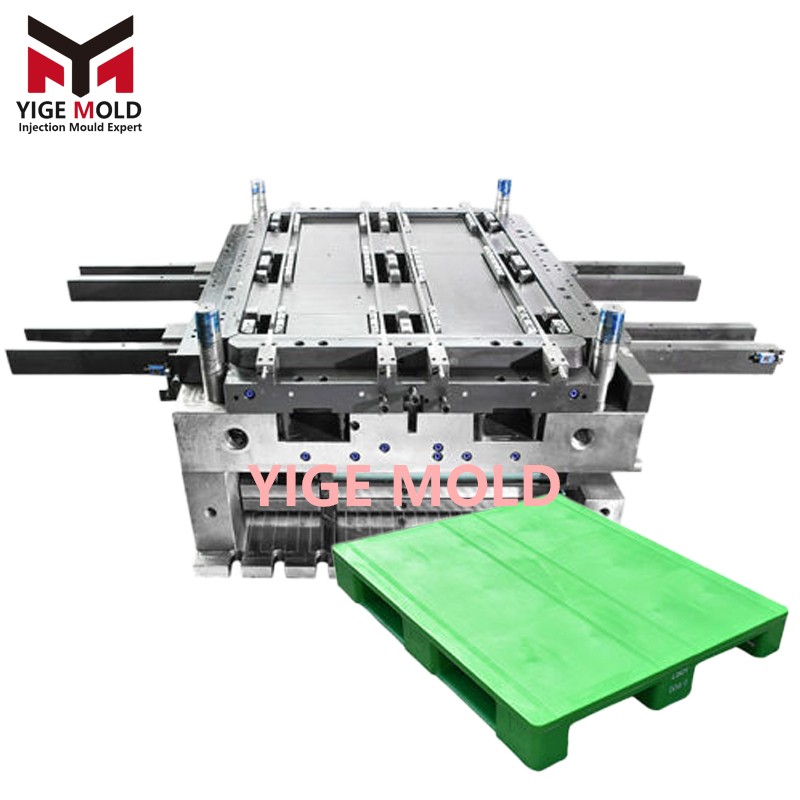

9-leg-4-way Pallet Mold

The 9-leg-4-way Pallet Mold professionally manufactured by Yige Mold adopts hot runner technology and is specifically designed for the logistics and warehousing industry. It molds the nine-leg structure pallet in a single cycle, featuring high load-bearing capacity, stable structure, and long service life, making it an ideal choice for cargo handling and warehouse stacking.

Technical Specifications (Yige Standard)

|

Parameter |

Specification |

|---|---|

|

Mold Type |

Hot Runner Injection Mold |

|

Cavity Quantity |

1-out-1 (Single Cavity) |

|

Mold Material |

P20/718H Pre-hardened Mold Steel (Yige Preferred) |

|

Cycle Time |

8-12 seconds/mold (Optimized Design) |

|

Daily Output |

700-800 pieces (24-hour Continuous Production) |

|

Mold Life |

Over 1.5 million cycles (Yige Quality Assurance Standard) |

|

Suitable Injection Machine |

1800-2500 tons (Large Machine Special) |

|

Product Dimensions |

1200×1000×150mm (Customizable) |

|

Product Weight |

18-22kg |

|

Yige Delivery Time |

35-45 days (Including Trial Run and Debugging) |

Yige Mold Technical Features

Hot Runner System: Utilizes an optimized valve-gate hot runner layout with a melt filling balance deviation of <3%, reducing runner waste by 65% and significantly lowering material costs.

Cooling System: Multi-circuit cooling channel design improves cooling efficiency by 35% and shortens cycle time by 18%, ensuring dimensional stability of the product.

Ejection Mechanism: A combined ejector pin and hydraulic slide ejection system is employed for the special structure of the nine-leg pallet, ensuring smooth and damage-free demolding.

Exhaust System: Multi-stage exhaust structure prevents gas traps and burn marks, stabilizing the defect rate at over 99.5%.

Product Performance

Load-Bearing Capacity: Dynamic load of 1.5 tons and static load of 4 tons, meeting the requirements of the logistics and warehousing industry.

Structural Design: Nine-leg support structure with reinforced ribs at the bottom, providing impact resistance and durability against aging.

Temperature Resistance: Long-term usability in environments ranging from -30°C to 65°C without deformation or cracking.

Wear Resistance: Smooth surface with excellent wear and corrosion resistance, ensuring long service life.

Yige Exclusive Services

Design Customization Support: Free DFM analysis and mold structure optimization solutions, supporting personalized designs such as anti-slip patterns, forklift holes, and stacking limiters.

Trial Run Verification Assurance: Conducts at least 3 complete trial runs at the Yige factory to ensure smooth mass production, providing trial run reports and process parameter packages.

Rapid Response System: 24/7 online technical support, 72-hour spare parts supply, and on-site service support from professional engineers.

Extended Warranty Commitment: Offers a 24-month extended warranty, lifetime maintenance services, and regular follow-up maintenance.

Application Areas

-

Logistics and Warehousing: Warehouse cargo stacking, handling, and turnover

-

Manufacturing Industry: Material turnover in factory workshops and production lines

-

Commercial Facilities: Supermarkets, shopping malls, wholesale markets

-

Agricultural Sector: Agricultural product storage and transportation

Cooperation Process

-

Requirement Communication → 2. Yige Solution Design → 3. 3D Structure Review → 4. Mold Manufacturing → 5. Factory Trial Run → 6. Mass Production → 7. After-Sales Follow-Up