Plastic Planter Mold

Plastic Planter Mold: Precision Injection Molding for Garden and Horticulture

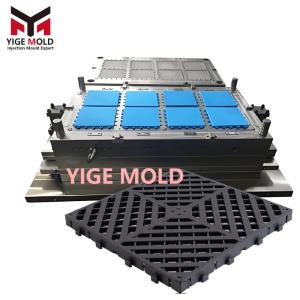

A plastic planter mold is a specialized injection molding tool designed for the mass production of plastic flower pots, garden planters, and horticultural containers. This precision-engineered equipment plays a crucial role in determining the final product's shape, quality, functionality, and production efficiency. The mold operates by injecting molten plastic material into its cavity under high pressure, where it cools and solidifies to form the finished planter product.

Core Manufacturing Process

The injection molding process for plastic planters follows a systematic six-stage cycle: mold clamping, injection, pressure holding, cooling, mold opening, and plastic planter removal. This continuous production cycle enables high-volume manufacturing with consistent quality output. Modern planter molds are typically designed as multi-cavity systems, allowing simultaneous production of multiple planters in a single cycle - commonly one-out-two or one-out-four configurations.

Material Selection and Technical Specifications

The choice of mold material is critical for long-term performance and product quality. Common materials include:

-

P20: Pre-hardened plastic die steel with HRC 28-33 hardness, ideal for long-term production of high-quality plastic molds with mold life exceeding 300,000 shots

-

718: Enhanced quenching capability with HRC 33-36 hardness, offering better performance in large-size plastic mold applications and mold life over 500,000 shots

-

H13: Hot work die steel requiring vacuum quenching to achieve hardness above HRC 43, with mold life exceeding 800,000 shots

-

S136: High-performance mold steel with HRC 48-52 hardness, capable of producing over 1,000,000 shots

Advanced Design Features

Modern plastic planter molds incorporate several sophisticated design elements:

Multi-Cavity Configuration: Enables simultaneous production of multiple planters, significantly boosting manufacturing efficiency and reducing per-unit costs.

Hot Runner System: Maintains molten plastic at optimal temperature throughout the injection process, reducing material waste and cycle times.

Precision Cooling Channels: Strategically designed cooling systems ensure uniform temperature distribution, preventing product deformation and shortening cycle times.

Automatic Ejection: Integrated ejection systems with pins and plates ensure smooth product removal without manual intervention.

Quality Control and Performance Standards

Professional mold manufacturers like Yige Mold implement rigorous quality control measures throughout the production process. Key performance indicators include:

-

Dimensional Tolerance: Typically maintained within ±0.01mm

-

Cycle Time: Average 45-60 days for T1 time

-

Mold Life: Capable of producing 50-500 million shots over 5-6 years, with proper maintenance extending to 10 years

-

Surface Finish: Options include high-gloss polishing, texture finishing, and EDM surface treatment

Customization Capabilities

Plastic planter molds can be fully customized to meet specific design requirements, including:

-

Various planter types (standard, self-watering, wall-mounted, modular)

-

Different materials (PP, PC, ABS, PET, PE, PVC, PMMA)

-

Custom colors and surface treatments

-

Brand logos and size indicators

-

Special features like built-in drainage systems or non-slip bases

Industry Applications

These molds serve diverse market segments including:

-

Home Gardening: Decorative planters for indoor and outdoor use

-

Commercial Horticulture: Production planters for nurseries and greenhouses

-

Landscape Architecture: Large planters for urban beautification

-

Retail Display: Decorative pots for retail environments

Technical Support and After-Sales Service

Reputable manufacturers like Yige Mold provide comprehensive support including:

-

2D/3D design and mold flow analysis using UG, Auto CAD, and Pro-E software

-

CNC milling, high-speed carving, and EDM processing

-

Mold assembly and surface finishing

-

Trial production and sample testing

-

1 year warranty or 1 million shot times with spare parts availability

The plastic planter mold industry continues to evolve with advancements in materials science, precision engineering, and automation technologies, enabling manufacturers to produce high-quality horticultural containers with improved efficiency and reduced environmental impact.