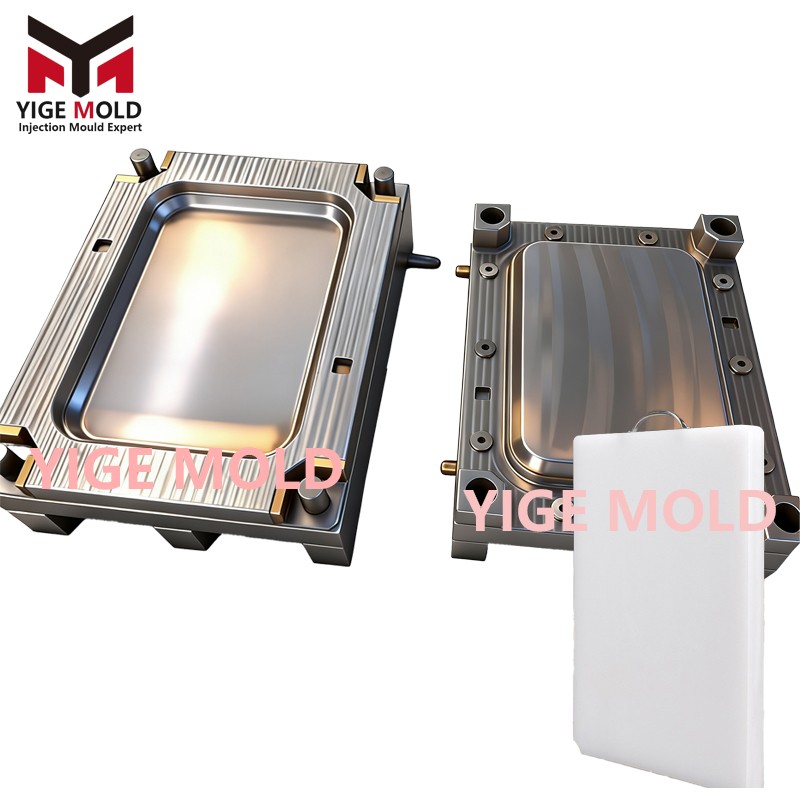

Plastic Chopping Board Mold

Plastic Chopping Board Mold: The Manufacturing Foundation of Kitchen Safety and Durability

Plastic Chopping Board Mold: The Manufacturing Foundation of Kitchen Safety and Durability

I. Product Positioning and Market Demand

Plastic chopping board molds represent a high-tech category within food-contact plastic product molds, with their products directly impacting food safety and kitchen work efficiency. Modern plastic chopping boards have evolved from simple cutting surfaces into intelligent kitchen tools integrating hygiene protection, functional zoning, and material innovation. Mold manufacturing must meet multiple performance requirements including food-grade safety standards, cut/impact resistance, warp resistance, ease of cleaning and maintenance, while also considering ergonomics and aesthetics.

With increasing consumer attention to kitchen hygiene, chopping boards are transitioning from traditional wood to high-performance plastics. Market data shows the global plastic chopping board market growing at an annual rate of 6.8%, with antibacterial, categorized-use, and smart sensing products becoming the main growth drivers. Mold manufacturers must adapt to this trend by developing production solutions that meet diverse needs.

II. Key Points in Mold Structure Design

1. Main Body Structure Design

A balanced layout of 1x2 or 1x4 cavities is adopted, with mold size determined by board dimensions (common specs: 30x20cm to 60x40cm). Thickness is designed between 1.5-2.5cm, using graduated wall thickness technology where edges are 20-30% thicker than the center to enhance impact resistance. The bottom incorporates a reinforcing grid structure, with grid width 8-12mm, depth 40-50% of wall thickness, and R3-R5 fillets at grid intersections to avoid stress concentration.

2. Anti-Slip System Design

The bottom anti-slip structure uses modular design. Standard models feature 4-8 anti-slip feet, with foot diameter 15-25mm, height 2-4mm, and reinforcement ribs at connection points with the main body. Premium models use annular anti-slip patterns, with pattern width 1-1.5mm, depth 0.5-0.8mm, spacing 3-5mm, and incline angle 15°-25°. Anti-slip feet feature a graduated connection design to the main board body, avoiding sharp transitions.

3. Functional Zoning Design

For categorized use needs, molds for multi-zone boards are designed. Slider mechanisms create partitions between different zones, with partition height 8-15mm and thickness 3-5mm. Edges incorporate juice grooves, with groove width 10-15mm, depth 3-5mm, and rounded transitions for easy cleaning. Premium versions integrate weighing areas, with number scales formed via inserts, scale depth 0.3-0.5mm.

III. Materials Engineering Innovation

1. Substrate Selection Strategy

Food-grade High-Density Polyethylene (HDPE) has become the mainstream choice, with Melt Flow Index 0.3-0.5 g/10min, density 0.95-0.96 g/cm³. Antibacterial products incorporate silver-ion or zinc oxide masterbatch, addition rate 1-3%. High-temperature resistant types use Polypropylene (PP), with Heat Deflection Temperature up to 110°C. Eco-friendly types use composite materials with 30-50% recycled plastic content, performance retention rate ≥85%.

2. Functional Additives

Anti-mold agent addition rate 0.5-1%, ensuring no mold spots in humid environments. Anti-static agent addition rate 0.3-0.8%, reducing surface dust adhesion. Colorants use food-grade organic pigments with migration resistance meeting FDA standards. Toughening agent addition rate 5-8%, improving impact resistance, falling dart impact strength ≥50 kJ/m².

3. Composite Structure Design

Development of three-layer co-extrusion molds: surface layer is antibacterial (thickness 0.3-0.5mm), middle layer is reinforcement (60-70% of total thickness), bottom layer is anti-slip (thickness 0.5-1mm). Mechanical interlock structures are set between layers, bonding strength ≥8 MPa. The wear resistance of composite boards is 2-3 times that of single-layer structures, extending service life by over 50%.

IV. Key Mold Manufacturing Technologies

1. Ultra-Mirror Polishing Process

Food-contact surfaces require A1 grade mirror polish (Ra ≤ 0.012 μm). A seven-stage polishing process is used: 600# sandpaper rough grinding → 1000# sandpaper fine grinding → 3μm diamond compound pre-polish → 1μm diamond compound fine polish → 0.5μm aluminum oxide polish → final chromium oxide polish → buffing with wool wheel. The entire process is conducted in a clean room to avoid secondary contamination.

2. Anti-Slip Texture Machining

Anti-slip textures are created via chemical etching, depth 0.4-0.6mm, texture uniformity error ≤0.05mm. Texture patterns are computer-aided designed to ensure a slip resistance coefficient between 0.65-0.75. Secondary polishing follows etching to remove sharp burrs, fillet radius ≥0.3mm.

3. Precision Temperature Control System

Multi-layer cooling channels are designed: surface channels 8-10mm from cavity surface, middle channels 12-15mm, bottom channels 15-18mm. Zoned control technology divides the mold into 6-8 temperature zones, temperature variation between zones ≤2°C. Cooling water flow is controlled at 15-20 L/min, inlet-outlet temperature difference ≤3°C.

V. Hygiene and Safety Assurance

1. Microorganism Protection Design

Surface roughness is controlled at Ra ≤ 0.2 μm, reducing bacterial adhesion potential. Edges feature smooth transitions with fillet radius ≥3mm, avoiding food residue accumulation. Bottom support protrusions ensure 3-5mm clearance from countertops, facilitating air circulation and cleaning.

2. Chemical Stability Assurance

Food-contact components are made from 316 or 420 stainless steel, chromium content ≥16%, nickel content ≥10%. Surfaces undergo passivation treatment, improving corrosion resistance 5-8 times. All plastic-contact surfaces are electropolished to eliminate micro-pits.

3. Cleaning Verification System

A cleaning verification mold is developed for microbial testing after simulated use. Cleaning standards are set: coliform bacteria undetectable, total bacterial count ≤10 CFU/cm². A cleaning procedure verification database is established to ensure design effectiveness.

VI. Quality Control System

1. Dimensional Accuracy Control

Full-dimensional inspection using Coordinate Measuring Machines (CMM): thickness tolerance ±0.2mm, flatness ≤0.3mm/300mm, warpage ≤0.5%. Anti-slip foot height tolerance ±0.1mm, positional tolerance ±0.15mm. Weight controlled within ±3% of nominal value.

2. Mechanical Performance Testing

Drop weight impact test: 1kg steel ball free fall from 1m height, surface shows no cracks. Cyclic loading test: 50kg load applied 1000 cycles, deformation ≤0.5mm. Knife cut test: Standard kitchen knife cuts 1000 times, cut depth ≤0.3mm.

3. Chemical Safety Testing

Migration testing per GB 4806.7 standard, heavy metal content complies. Formaldehyde emission test: emission ≤1.5 mg/L. Antioxidant migration test: migration ≤0.05 mg/dm².

VII. Production Efficiency Optimization

1. Rapid Molding Technology

Sequential valve control technology reduces injection time by 20%. Development of rapid cooling system reduces cooling time 15-20%. Optimized ejection system reduces ejection stroke 30%, cycle time controlled at 35-45 seconds.

2. Automated Production Integration

Configuration of automatic part removal robots, pick time ≤3 seconds. Integrated vision inspection system, inspection speed ≤2 seconds/part. Establishment of automated packaging line, packaging speed ≥20 pieces/minute. Development of mold health monitoring system, real-time monitoring of 32 parameters including temperature and pressure.

3. Energy Consumption Management Optimization

Closed-loop control of hot runner reduces energy consumption 25-30%. Variable frequency control of cooling system reduces pump energy use 40%. Insulation added to mold exterior reduces heat loss 20%. Optimized heating power configuration reduces total power 15%.

VIII. Application Scenario Expansion

1. Household Series

Development of size-graded products: Small (25x15cm) for fruits, Medium (35x25cm) for daily use, Large (45x30cm) for meat processing. Color coding for categorization: Red for raw meat, Blue for seafood, Green for vegetables, White for cooked food.

2. Commercial Series

Restaurant boards increased to 3-4cm thickness, wear resistance improved 50%. Development of lipped board design, edge height 2-3cm, preventing juice spillage. Integrated antibacterial technology, antibacterial rate ≥99.9%. Addition of anti-slip strips on bottom, slip resistance coefficient ≥0.8.

3. Special Applications

Development of high-temperature resistant boards, washable in dishwashers (withstands 120°C). Development of lightweight boards, weight reduced 30% while strength maintained. Development of foldable boards, volume reduced 70% when folded for easy storage.