plastic rattan chair mold

plastic rattan chair mold is the core forming equipment for the large-scale production of plastic rattan chairs. It is specially designed for environmentally friendly materials such as PP and PE, and can complete the forming of key components such as the seat, backrest, and armrests in one step. It accurately reproduces the texture, smooth curves, and hollow beauty of natural rattan weaving, achieving a high-quality replication of "plastic replacing rattan". Please provide the text you would like translated.

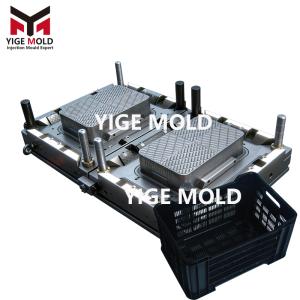

The core material of the mold is made of high-quality P20 and H13 die steel, which is processed by precision CNC and mirror polishing. The cavity surface is smooth and flawless, ensuring that the formed products have no burrs and a fine touch, with an extremely high degree of simulation of rattan weaving. In response to the demolding difficulties of the irregular structure of the rattan chair, an innovative combination solution of "optimized parting surface design + inclined top mechanism + core-pulling system" is adopted, combined with strict dimensional tolerance control of ±0.02mm, to ensure product consistency and forming stability. Please provide the text you would like translated.

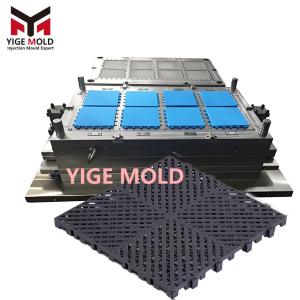

To enhance mass production efficiency, the mold is equipped with high-efficiency cooling water channels that fit the cavity contour, which can rapidly reduce the mold temperature and compress the single mold forming cycle to 30-60 seconds. The mold base adopts a standardized and modular design, featuring strong universality of accessories, low maintenance costs, and excellent wear resistance and corrosion resistance. Its service life can reach over 500,000 mold cycles, balancing efficiency and durability.

The core material of the mold is made of high-quality P20 and H13 die steel, which is processed by precision CNC and mirror polishing. The cavity surface is smooth and flawless, ensuring that the formed products have no burrs and a fine touch, with an extremely high degree of simulation of rattan weaving. In response to the demolding difficulties of the irregular structure of the rattan chair, an innovative combination solution of "optimized parting surface design + inclined top mechanism + core-pulling system" is adopted, combined with strict dimensional tolerance control of ±0.02mm, to ensure product consistency and forming stability. Please provide the text you would like translated.

To enhance mass production efficiency, the mold is equipped with high-efficiency cooling water channels that fit the cavity contour, which can rapidly reduce the mold temperature and compress the single mold forming cycle to 30-60 seconds. The mold base adopts a standardized and modular design, featuring strong universality of accessories, low maintenance costs, and excellent wear resistance and corrosion resistance. Its service life can reach over 500,000 mold cycles, balancing efficiency and durability.

Write your message here and send it to us