rattan style chair mold

rattan style chair mold is the core tool for efficient production of imitation rattan furniture. Traditional hand-woven rattan chairs are time-consuming and labor-intensive, while the application of molds enables standardized and mass production, bringing the beauty of rattan craftsmanship to more households.

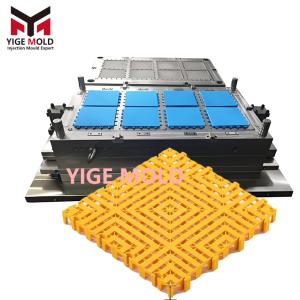

The rattan chair mold is mainly made of P20 and H13 steel. It is processed by CNC to form the shape, perfectly replicating the texture and curves of the rattan strips. The inner wall of the mold is smooth, ensuring that the resin or plastic material can fill every detail under high pressure, and after cooling, form a realistic appearance of rattan. A set of molds usually consists of upper and lower molds and multiple sliders to shape complex curved surfaces such as armrests and backrests.

The rattan chair components produced using molds have uniform sizes, stable structures, and are waterproof and moisture-resistant, making them easy to clean. Molded production significantly reduces costs, transforming rattan chairs from handmade artworks into practical and widely available household items.

The rattan chair mold is mainly made of P20 and H13 steel. It is processed by CNC to form the shape, perfectly replicating the texture and curves of the rattan strips. The inner wall of the mold is smooth, ensuring that the resin or plastic material can fill every detail under high pressure, and after cooling, form a realistic appearance of rattan. A set of molds usually consists of upper and lower molds and multiple sliders to shape complex curved surfaces such as armrests and backrests.

The rattan chair components produced using molds have uniform sizes, stable structures, and are waterproof and moisture-resistant, making them easy to clean. Molded production significantly reduces costs, transforming rattan chairs from handmade artworks into practical and widely available household items.

Write your message here and send it to us