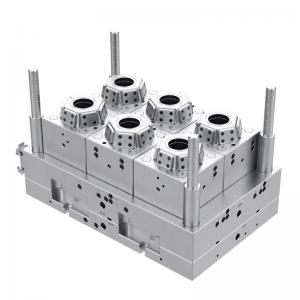

Portable Table Mold

Portable Table Mold - Yige Molds Professional Injection Molding Solution

Portable Table Mold - Yige Molds Professional Injection Molding Solution

I. Product Overview

The portable table mold is a professional mold equipment used for manufacturing various types of portable tables, utilizing injection molding processes to produce lightweight, durable, foldable, or detachable table products. With 17 years of injection mold manufacturing experience, Yige Molds specializes in providing high-quality customized portable table mold services, with products widely used in outdoor camping, household use, office scenarios, and other fields.

II. Core Design Points

1. Structural Design Optimization

-

Folding Mechanism Design: Adopts multi-stage folding structures, ensuring volume compression ratios of 4:1 to 6:1 after folding for easy carrying and storage

-

Snap Connection System: Table legs and tabletop use snap connections for quick installation and stable reliability, withstanding over 10,000 folding cycles

-

Lightweight Design: Through optimized structural design, product weight is controlled within 2-8 kg range, with load-bearing capacity reaching 30-50 kg

2. Material Selection

-

Tabletop Material: Uses PP (polypropylene) or PC (polycarbonate) materials, with calcium carbonate added to PP to enhance material performance, and PC used for fully transparent products

-

Mold Steel: Employs high-quality mold steels such as P20, 718H, 2738, with hardness controlled between HRC33-62, ensuring mold service life

-

Surface Treatment: Cavity surfaces undergo chrome plating or PVD coating treatment, achieving roughness of Ra≤1.6μm, enhancing product surface finish

3. Functional Configuration

-

Anti-slip Design: Anti-slip bumps on tabletop bottom and wear-resistant pads on table legs ensure usage stability

-

Multi-functional Integration: Some products feature height adjustment, tabletop angle adjustment, and other intelligent functions to meet different usage scenarios

-

Modular Design: Uses modular connection structures for easy assembly and maintenance, improving product flexibility

III. Technical Advantages

1. High-Precision Molding

-

Uses five-axis machining centers for precision processing, with cavity accuracy controlled within ±0.02mm

-

Through high-precision mold production, ensures accurate product dimensions, smooth surfaces, and smooth opening/closing

-

Positioning slot dimensional accuracy reaches ±0.1mm, ensuring seamless integration with automated logistics equipment

2. Efficient Cooling System

-

Uses zoned temperature control and efficient cooling systems, maintaining cavity temperature differences ≤±2°C

-

Cooling system adopts conformal cooling technology, using 3D printing to create cooling channels, improving cooling efficiency by approximately 30%

-

Water channel spacing controlled at 20-30mm, ensuring uniform cooling of large structures and preventing warping deformation

3. Material Compatibility

-

Mold materials use high-quality mold steels such as P20, 718H, 2738, with hardness controlled between HRC33-62

-

High-frequency friction areas like sliders and core pins use tungsten steel inserts with surface nitriding treatment, hardness reaching above HV900

-

Surface treatment processes achieve cavity roughness of Ra≤1.6μm, enhancing product surface finish

4. Structural System Optimization

-

Multi-point synchronized ejection system, ejection pin density at least 2 per 100cm², ensuring smooth demolding of large products

-

Optimized exhaust system design, vent hole dimensions set at 0.03-0.05mm, preventing defects like bubbles and shrinkage porosity

-

"Avoidance layout" parting surface design, adjusting parting lines from stress areas to non-stress areas, avoiding flash residue

IV. Yige Molds Service Advantages

1. Technical Expertise

-

Yige Molds has professional design teams and 17 years of injection mold manufacturing experience, with engineering teams able to provide customized mold solutions within 14 working days based on specific customer requirements

-

Uses CAD/CAM software for 3D modeling, combined with Moldflow molding analysis technology, simulating parameters like melt flow, filling pressure, and shrinkage deformation in advance, optimizing gate positions and cooling system layouts

-

Uses modular hot runner technology and multi-layer cooling structure design, shortening molding cycles by 25%, with daily production capacity reaching 300-800 pieces

2. Quality Assurance

-

Each mold undergoes strict quality inspection and trial verification, with three-coordinate measurement of grid dimensional tolerances ±0.15mm

-

Mold key components use slow wire EDM machining with accuracy reaching ±0.005mm

-

Mold lifespan exceeds 800,000 cycles, product dimensional tolerances controlled within ±0.1mm

-

Surface finish Ra≤0.08μm ensures stable batch-to-batch product quality

3. After-sales Service

-

Provides 24-hour technical support teams to solve various production problems

-

Common spare parts delivered within 48 hours to minimize customer downtime losses

-

Establishes mold asset management platforms allowing customers to view mold usage status, maintenance records, and remaining lifespan predictions online

-

When molds reach service life, recycling and renovation services are provided, restoring mold performance to over 80% by replacing key components and repairing worn parts

4. Cost Advantage

-

Through mass production and optimized processes, provides customers with the most competitive prices

-

Implements a standardized and customized mold development model, establishing a comprehensive mold standard parts library covering mold bases, ejector pins, guide pillars, bushings, etc., reducing mold design and processing time, lowering costs

-

Optimized gating system using hot runner technology reduces material waste by 15%-20% compared to traditional cold runners

-

Improved cooling system design using variable frequency pumps to regulate cooling water flow reduces energy consumption by 30%

V. Reasons to Choose Yige Molds

1. Professional Team

-

Has experienced design engineers and technical personnel teams capable of quickly responding to customer needs

-

Provides full-process services from product design, mold manufacturing to injection molding

-

Offers professional technical advice and optimization solutions based on customer product characteristics and usage scenarios

2. Advanced Equipment

-

Equipped with advanced processing equipment including CNC milling machines, high-speed engraving machines, EDM machines, wire cutting machines

-

Uses high-precision measuring instruments to ensure mold processing accuracy and product quality

-

Possesses comprehensive testing equipment and quality control systems, ensuring products meet customer requirements

3. Rapid Response

-

Provides 30-day free trial period to ensure mold performance meets standards and products comply with customer requirements

-

Conducts pre-trial water channel sealing tests and ejection mechanism flexibility checks

-

Uses stepped parameter adjustment methods to systematically record product molding data under different injection pressures, temperatures, and speed combinations

-

Trial products undergo 3D scanning detection, combined with mechanical performance test data, using reverse engineering technology to optimize molds

4. Customization Services

-

Supports small-batch customization and large-scale production to meet different customer needs

-

Can perform mold design and manufacturing based on customer-provided samples, drawings, or creative concepts

-

Offers multiple material and process options to meet different product performance requirements