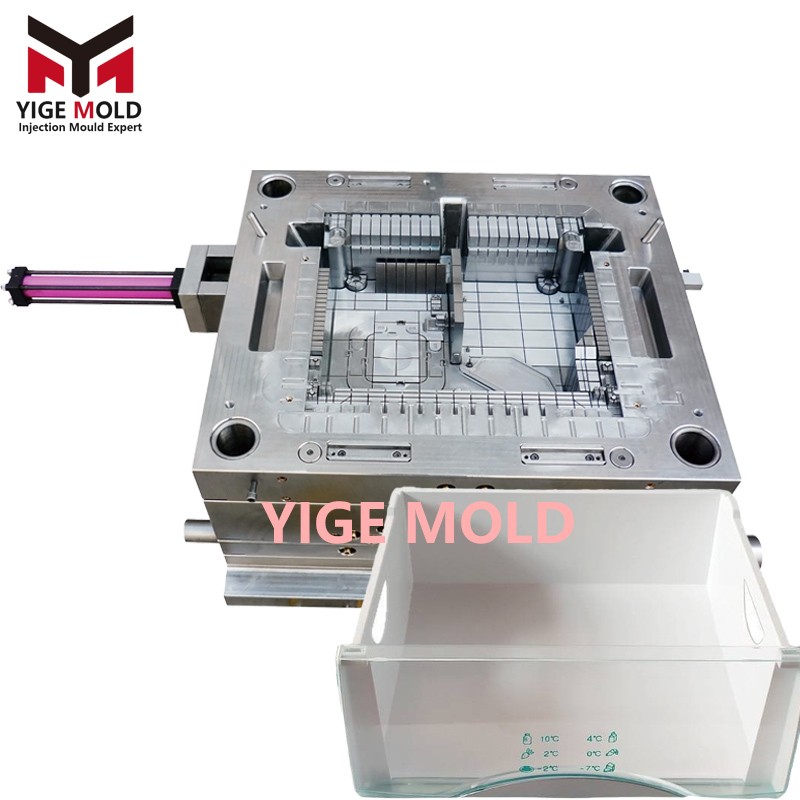

Refrigerator drawer mold

Introduction to the Injection Mold for Refrigerator Drawers

Yige Mold, as a professional manufacturer in the industry, focuses on the research and production of high-standard injection molds for refrigerator drawers. These molds are the core precision equipment used for efficient mass production of plastic drawers inside refrigerators.

Due to the complex structure and strict size requirements of refrigerator drawers, Yige Mold focused on solving the problems of forming and demolding caused by deep cavities and thin walls in the design. The molds generally adopt multi-point hot runner systems and efficient continuous cooling water channels to ensure uniform filling of the plastic parts and rapid cooling, thereby minimizing deformation and shortening the cycle. To address the inverted features around the drawer, Yige Mold utilized mature inclined top and side cylinder lateral core ejection mechanisms to achieve stable ejection of complex structures.

In the manufacturing process, Yige Mould selects high-quality pre-hardened mould steel, combines precise processing with professional surface treatment technologies (such as high-gloss polishing or fine etching), to meet the strict requirements of drawer products for appearance texture, dimensional accuracy and durability. At the same time, Yige Mould actively adopts new materials and new technologies to meet the forming needs of special plastics with glass-like texture and antibacterial properties, and integrates automation functions to provide customers with stable, efficient and integrated mould solutions.

Yige Mold, with its profound understanding of the home appliance industry and its advanced manufacturing capabilities, has produced excellent injection molds for refrigerator drawers. These molds excel in terms of stability, durability and production efficiency. They are trusted partners by many renowned home appliance brands and are dedicated to creating long-term value for customers.