Bathtub tooling

Bathtub Tooling: The Comprehensive Engineering Foundation for Modern Manufacturing

Bathtub Tooling: The Comprehensive Engineering Foundation for Modern Manufacturing

In modern bathtub production, tooling represents the complete set of specialized equipment, fixtures, and technical systems required to transform design concepts into serial-produced, high-quality products. Unlike the specific focus of an injection mold, Bathtub Tooling encompasses the entire manufacturing ecosystem—from initial forming and structural shaping to assembly, finishing, and quality verification. It is the integrated infrastructure that enables efficiency, precision, and scalability in manufacturing.

I. Core Components: An Interdependent System of Precision

Bathtub tooling is a multi-layered system where each element must function in precise coordination with others to achieve consistent output.

-

Primary Forming Tools

-

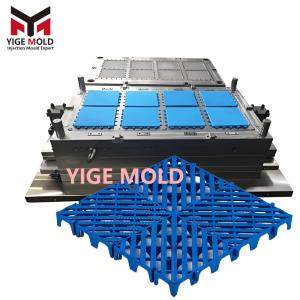

Molding Tools: This category includes the specific tooling required for the chosen material and process, such as injection molds for acrylic/ABS composites, compression molds for cultured marble, FRP lay-up molds for fiberglass, or casting patterns for metal bathtubs. These tools directly create the primary shape and surface finish of the product.

-

-

Supporting and Secondary Process Tooling

-

Assembly & Welding Fixtures: For bathtubs composed of multiple components (e.g., a steel tub with a separate apron), precision welding jigs and assembly fixtures ensure all parts align perfectly, guaranteeing dimensional consistency and joint integrity.

-

Machining Fixtures: Dedicated CNC holding fixtures and drilling templates are used for accurately creating cutouts for drains, overflow ports, and faucet holes, as well as for trimming edges. They ensure machining accuracy and repeatability.

-

Finishing & Handling Tools: This includes trimming dies for removing flash, polishing mandrels for surface refinement, and specialized handling racks that protect the product during transport between stages.

-

-

Measurement, Inspection, and Validation Tools

-

Quality Control Gauges: Custom check fixtures and CMM inspection programs are created from the product's digital master model. They allow for rapid verification of critical dimensions, contours, and hole patterns against tight tolerances.

-

Surface and Leak Test Equipment: Specialized water-testing stations and visual inspection lighting rigs are part of the tooling suite to validate functionality and finish quality consistently.

-

II. System-Specific Design: Tailored for Material and Process

The configuration of bathtub tooling varies fundamentally based on the chosen manufacturing method.

-

For Acrylic/Fiberglass Bathtubs:

The tooling system is typically a two-stage process. It begins with a high-gloss, female forming tool (often nickel-electroformed or high-grade composite) used for vacuum-forming the acrylic sheet. This skin is then transferred to a separate, structurally robust laminating mold where fiberglass reinforcement is applied via spray-up or hand lay-up. The tooling system must manage thermal expansion, material adhesion, and precise alignment between the two stages.

-

For Cast Iron/Steel Bathtubs:

The tooling revolves around metal forming. For steel tubs, massive stamping dies are the core, engineered for deep draws and metal flow. For cast iron, the system consists of precision sand-casting patterns and core boxes used to create the disposable sand molds into which iron is poured. The tooling must account for material shrinkage, surface finish for enamel coating, and draft angles for pattern removal.

-

For Solid Surface or Cultured Marble:

The process relies on gel-coated composite molds and often involves mixing/dispensing equipment for the resin and filler. The molds must produce a high-quality surface finish directly and are designed for easy demolding of the cured product.

III. Core Value: Enabling Manufacturing Excellence

Investing in a comprehensive, well-engineered tooling system delivers value across the entire product lifecycle and business operation.

-

The Engine of Production Scalability: Proper tooling transforms a prototyping effort into a repeatable manufacturing process. It standardizes steps, reduces reliance on artisan skill, and enables predictable cycle times, which is essential for scaling production to meet market demand.

-

The Guardian of Product Consistency: The primary purpose of tooling is precise replication. High-quality fixtures and molds ensure that the ten-thousandth unit is virtually identical to the first in fit, form, and function, which is the cornerstone of brand reputation and customer trust.

-

The Enabler of Design Fidelity: Complex organic shapes, integrated features, and stringent ergonomic requirements cannot be mass-produced consistently by hand. Advanced tooling, often manufactured via 5-axis CNC machining from digital models, is the essential link that faithfully translates a designer's vision into a tangible, reproducible product.

-

The Determinant of Long-Term Cost and Flexibility: While the initial capital outlay is significant, robust tooling with a long service life drives down the per-unit amortized cost. Furthermore, modular tooling design—using interchangeable inserts or adaptable fixtures—allows for cost-effective production of product variants and faster adaptation to new designs.

Conclusion

Bathtub Tooling represents the materialization of manufacturing intent. It is the critical, physical infrastructure that sits between a brilliant design and a commercially successful product. More than just individual tools, it is a holistic system designed for repeatability, quality, and efficiency. In an industry driven by aesthetics, durability, and value, excellence in tooling design and execution is not merely an operational expense—it is a fundamental strategic investment. It defines a manufacturer's capability to innovate with confidence, compete on quality, and deliver reliably at scale. Ultimately, bathtub tooling is the unsung hero that makes high-quality sanitaryware an accessible reality, forming the very foundation upon which modern bathroom manufacturing is built.