Anti-slip Plastic Floor Mold

Yige Molds - Professional Anti-Slip Plastic Floor Mold Manufacturer

Yige Molds is a professional manufacturer of anti-slip plastic floor molds, specializing in providing high-precision and efficient injection mold solutions for the plastic flooring industry. With over 10 years of experience in mold manufacturing, the company employs advanced CAD/CAM 3D design technology to ensure mold cavity precision reaches micrometer-level accuracy.

Product Advantages

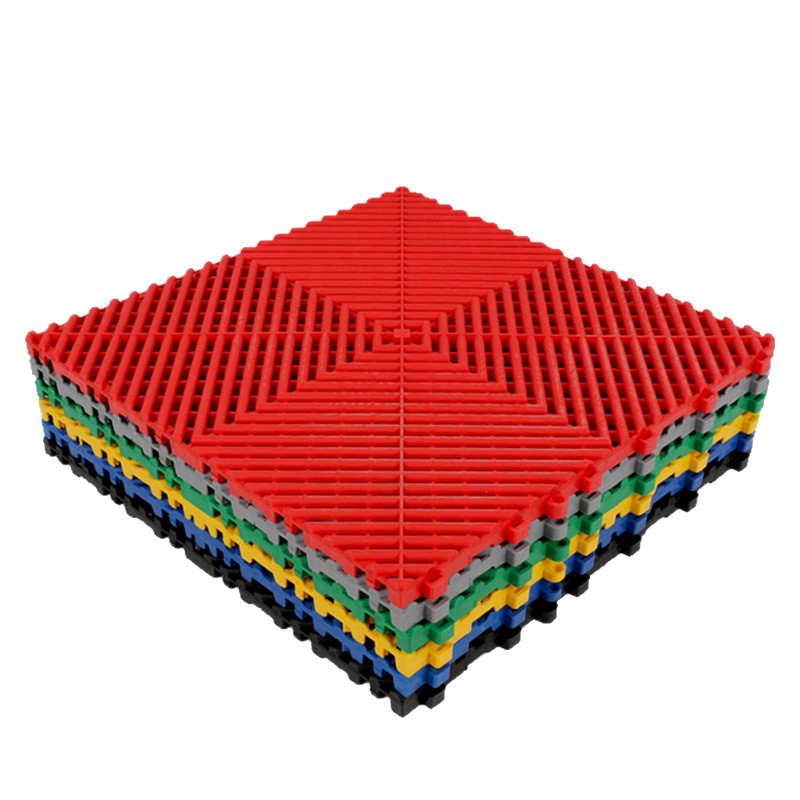

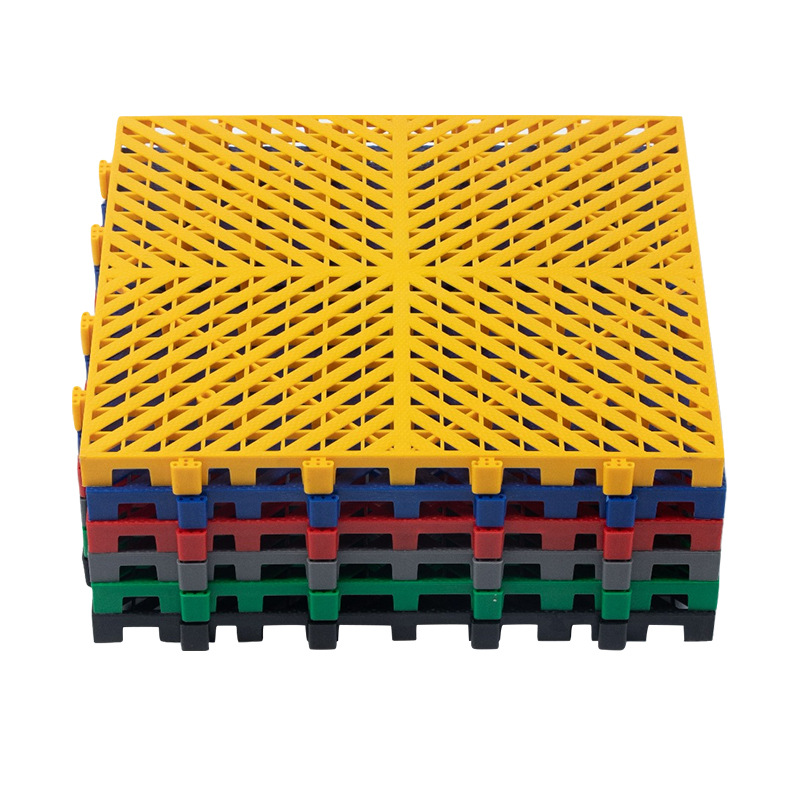

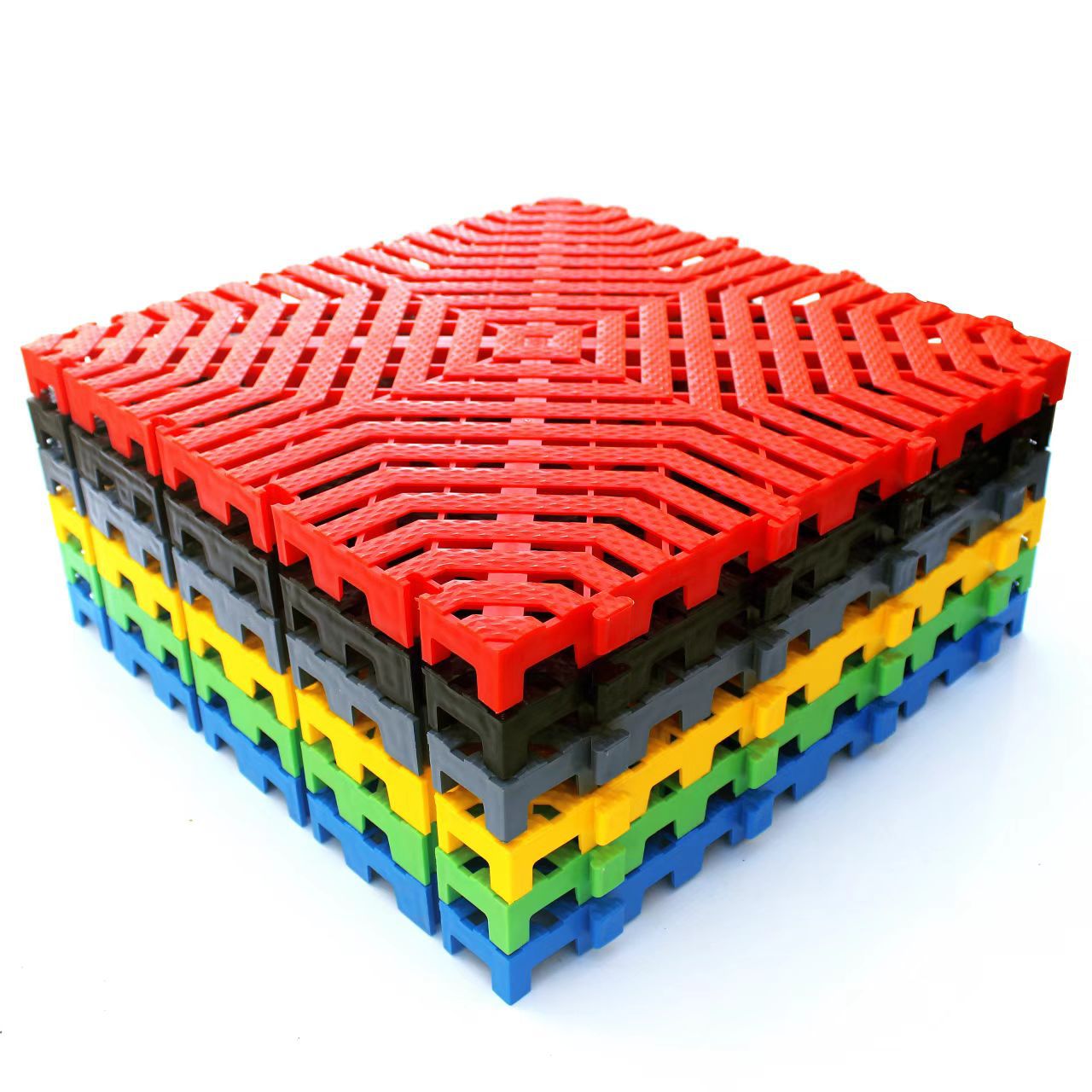

Yige Molds uses high-quality mold steels such as P20, 718, and S136, which undergo heat treatment processes like tempering, quenching, and nitriding to achieve hardness levels of HRC 35-38. The mold lifespan can reach 500,000 to 2 million cycles. The mold surface is designed with special anti-slip groove structures, utilizing a combination of diamond-shaped and circular cores to create anti-slip textures on the floor surface, enhancing friction coefficient. Equipped with optimized cooling channel systems, the molds employ cold runner or hot runner technology, combined with copper tube and aluminum fin heat exchangers, to achieve rapid cooling and molding, significantly improving production efficiency.

Technical Capabilities

Yige Molds utilizes advanced processing equipment, including CNC machining centers, high-speed milling machines, EDM (Electrical Discharge Machining), and wire-cutting machines, strictly adhering to the ISO9001 quality management system. The molds support injection molding with various plastic materials such as PVC, PP, HDPE, and PC. Mold cavity configurations, including 1-out-1 and 1-out-2 setups, can be customized according to customer requirements.

Applications

The anti-slip plastic floors produced using Yige Molds are widely used in various fields, including residential decoration, commercial buildings, public facilities, and industrial plants. The products feature waterproof and anti-slip properties, wear resistance, durability, environmental safety, and are particularly suitable for flooring in crowded places such as schools, hospitals, shopping malls, and factory workshops.

Service Commitment

Yige Molds offers end-to-end services from design and manufacturing to debugging, with sample production cycles ranging from 35 to 85 days, a one-year warranty, and lifelong maintenance. The company boasts a professional design team that provides technical support and prompt responses to address various production challenges. Leveraging the advantages of large-scale production, Yige Molds delivers the most competitive prices to customers. For more information or to request a customized solution, please feel free to contact us.