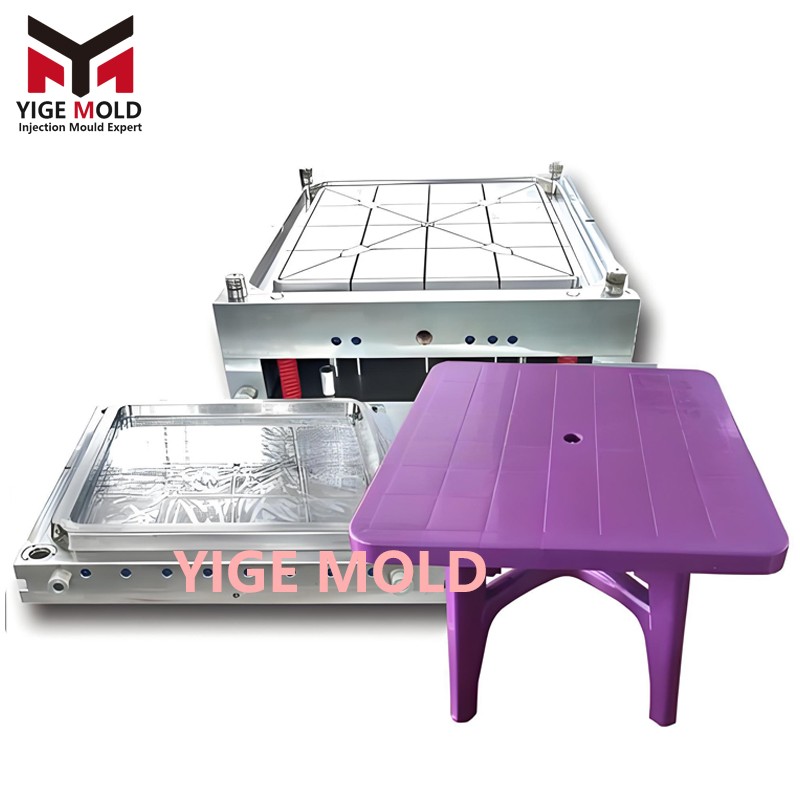

Plastic table mold

The plastic table mold is a core product of Yige Mold, which focuses on the mass injection molding of plastic table bodies. Its design and manufacturing aim to achieve efficient, stable and large-scale production of the product.

The molds strictly adopt high-quality mold steels such as P20 and 718H, and undergo precise CNC machining and heat treatment processes, ensuring the molds themselves have high hardness, high wear resistance and a long service life. A standard mold produced by Yige Molds fully includes the cavity for forming the desktop, the core for the supporting structure, as well as an efficient and balanced cooling system, a reliable ejection system and a runner system.

The standardized workflow of its process involves melting the plastic raw materials and then injecting them under high pressure into a closed mold cavity. After rapid shaping through an internal cooling system, the parts are automatically ejected by the ejection mechanism. The advantage of Yige molds lies in its ability to precisely process the mold cavity to produce plastic table bodies with highly uniform dimensions, clear surface textures, and stable structures in a single molding process. Its mature design enables multi-cavity molds, significantly enhancing the production efficiency and capacity of customers.

As a key carrier for transforming plastic tables from blueprints to products, the solutions provided by Yige Mould deeply reflect its integrated understanding of material properties, molding processes, and precision manufacturing technologies, serving as a solid foundation for ensuring the quality and market competitiveness of the final products.

The molds strictly adopt high-quality mold steels such as P20 and 718H, and undergo precise CNC machining and heat treatment processes, ensuring the molds themselves have high hardness, high wear resistance and a long service life. A standard mold produced by Yige Molds fully includes the cavity for forming the desktop, the core for the supporting structure, as well as an efficient and balanced cooling system, a reliable ejection system and a runner system.

The standardized workflow of its process involves melting the plastic raw materials and then injecting them under high pressure into a closed mold cavity. After rapid shaping through an internal cooling system, the parts are automatically ejected by the ejection mechanism. The advantage of Yige molds lies in its ability to precisely process the mold cavity to produce plastic table bodies with highly uniform dimensions, clear surface textures, and stable structures in a single molding process. Its mature design enables multi-cavity molds, significantly enhancing the production efficiency and capacity of customers.

As a key carrier for transforming plastic tables from blueprints to products, the solutions provided by Yige Mould deeply reflect its integrated understanding of material properties, molding processes, and precision manufacturing technologies, serving as a solid foundation for ensuring the quality and market competitiveness of the final products.

Write your message here and send it to us