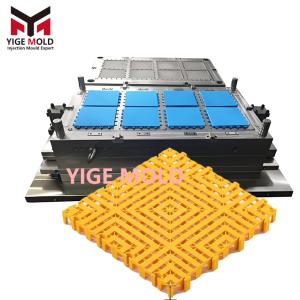

Stackable Container Mold

Comprehensive Technical Analysis of Stackable Plastic Tub Molds: Design Philosophy and Production Optimization Solutions

Comprehensive Technical Analysis of Stackable Plastic Tub Molds: Design Philosophy and Production Optimization Solutions

1. Product Definition and Market Value

1.1 Core Characteristics of Stackable Plastic Tubs

Stackable plastic tub molds are specialized forming tools for manufacturing plastic containers with stacking functionality. The core design feature lies in enabling safe, stable multi-layer stacked storage while ensuring the tub's normal functionality, significantly improving warehouse and transportation space utilization.

1.2 Market Differentiation Advantages

-

Space Efficiency: Saves 60-70% of storage space when stacked

-

Logistics Optimization: Reduces transportation costs by over 40%

-

Usage Convenience: Enables easy stacking and separation with one hand

-

Product Protection: Stacking structure prevents scratches and deformation

2. Structural Innovations in Mold Design

2.1 Key Points in Stacking Structure Design

Stacking Guidance System

-

Uses tapered guide posts and corresponding guide grooves with a taper of 3-5°

-

Bottom reinforcement ribs precisely correspond to support points of the upper tub bottom

-

Four-corner positioning structure ensures automatic centering during stacking

Stacking Limiting Mechanism

-

Stacking height limit design prevents excessive compression

-

Optimized limit contact area avoids stress concentration

-

Elastic buffer structure protects tub edges

Separation Assistance Design

-

Separation groove depth: 8-12mm, width: 15-20mm

-

Anti-vacuum venting grooves prevent vacuum adhesion after stacking

-

Separation force controlled within 15-30N range

2.2 Mold Materials and Process Innovations

Special Steel Applications

-

Core and cavity: Select high-polishability steels such as S136H, NAK80

-

Guide components: Use ASSAB 8407 with excellent wear resistance

-

Ejection system: Uses high-strength SKD61 heat-treated to HRC 50-54

Surface Treatment Technology

-

Cavity mirror polishing to #8000-10000 grit

-

TiN coating on guide areas, hardness reaching HV2500

-

Special texture treatment on separation groove areas to reduce friction

3. Precision Manufacturing Process

3.1 Key Machining Technologies

High-Precision CNC Machining

-

Five-axis simultaneous machining center, accuracy ±0.005mm

-

High-speed milling technology, surface roughness below Ra0.4μm

-

Stacking mating surfaces processed with slow wire EDM, accuracy ±0.002mm

Special Process Treatments

-

Guide grooves processed with precision EDM

-

Separation groove areas treated with ultrasonic polishing

-

Mating surfaces undergo matching and lapping, contact area ≥85%

3.2 Inspection and Verification System

3D Inspection Technology

-

Blue light 3D scanning for full-dimensional accuracy inspection

-

CMM measurement of stacking fit clearance, controlled within 0.1-0.3mm

-

Geometric tolerance inspection, flatness ≤0.1mm/100mm

Function Test Verification

-

Continuous stacking test: 10-layer stacking stability verification

-

Separation force test: 5000 separation cycle tests

-

Load test: 200kg/layer load capacity in stacked state

4. Production Technology Parameter Optimization

4.1 Special Requirements for Injection Molding Process

Precise Temperature Control

-

Zoned mold temperature control, temperature deviation in stacking areas ≤±1°C

-

Independent hot runner temperature control, individual adjustment for each gate

-

Optimized cooling system ensuring uniform cooling

Precision Pressure Adjustment

-

Segmented injection speed control to avoid stress at stacking structures

-

Multi-stage holding pressure settings, focusing on dimensional stability of mating surfaces

-

Precise back pressure control ensuring uniform material density

4.2 Quality Control Standards

Dimensional Control Standards

-

Stacking guide diameter tolerance: ±0.05mm

-

Tub opening flatness: ≤0.2mm

-

Wall thickness uniformity: Deviation at any point ≤5%

Function Test Standards

-

Stacking stability: 10-layer stacking offset ≤2mm

-

Separation effect: One-hand separation force 15-25N

-

Cycle durability: 10000 stacking/separation cycles without damage

5. Production Efficiency Optimization Solutions

5.1 Mold Structure Optimization

Quick Mold Change Design

-

Standardized positioning system, mold change time ≤15 minutes

-

Modular cooling water channels with quick-connect design

-

Automated ejection system reducing manual intervention

Production Efficiency Improvement

-

Hot runner system optimization reducing cycle time by 20%

-

Multi-cavity mold design increasing capacity 3-5 times

-

Automated take-out system enabling unmanned production

5.2 Production Management Optimization

Intelligent Monitoring

-

Real-time mold status monitoring system

-

Online product quality inspection devices

-

Production process data collection and analysis

Preventive Maintenance

-

Key component life warning system

-

Automatic regular maintenance plan reminders

-

Intelligent spare parts inventory management system

6. Comprehensive Cost-Benefit Analysis

6.1 Investment Return Analysis

Mold Investment Comparison

-

Standard plastic tub molds: 80,000-120,000 RMB

-

Stackable plastic tub molds: 120,000-180,000 RMB (50% premium)

-

Investment payback period: 6-12 months (through logistics savings)

Production Cost Optimization

-

Warehouse cost reduction: 60-70%

-

Transportation cost reduction: 40-50%

-

Packaging cost reduction: 80-90%

6.2 Capacity Efficiency Improvement

Production Efficiency Data

-

Single mold daily output: Conventional design 800-1200 pieces, optimized design 1500-2000 pieces

-

Mold lifespan: Conventional molds 800,000-1 million cycles, premium molds 1.2-1.5 million cycles

-

Comprehensive efficiency improvement: 25-35%

Conclusion

Stackable plastic tub molds represent an important development direction in plastic container mold technology. Their technical sophistication is reflected not only in precision manufacturing processes but also in deep understanding of user scenarios and innovative design. Selecting a professional stackable plastic tub mold manufacturer requires comprehensive consideration of design capability, manufacturing precision, production experience, and after-sales service. As logistics efficiency and space utilization requirements continue to increase, stackable plastic tub products with stable stacking performance, convenient operation, and long-term durability will play significant roles in more application areas.