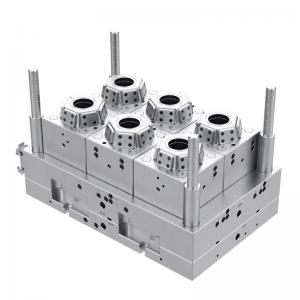

Plastic Drum Mold

Yige Mold: Professional Manufacturer of Plastic Drum Molds

Yige Mold: Professional Manufacturer of Plastic Drum Molds

Professional Manufacturing for Industrial Safety

In modern industries such as chemical, food, pharmaceutical, and logistics transportation, plastic drums are the most important storage and transportation containers for liquid and solid materials. Their quality directly affects production safety and transportation efficiency. As a leading enterprise with twenty years of professional mold manufacturing experience, Yige Mold specializes in the field of plastic container molds, providing customers with comprehensive solutions from design to mass production.

Product Positioning and Technical Advantages

Precision Design and Professional Manufacturing

Yige Mold focuses on the research, development, and manufacturing of molds for plastic drums, including standard 200L/220L chemical drums, food-grade storage and transport drums, IBC tote tank liners, and more. We adopt a modular design concept and develop various specifications of professional molds, such as closed-head drums, open-head drums, and conical drums, tailored to the needs of different industries.

Core Technical Advantages

-

Structural Strength Optimization Technology: By combining finite element analysis with actual testing, we design scientifically arranged reinforcement ribs in key areas of the drum body to ensure structural integrity under a 1.8-meter drop test and 3-4 layers of stacking pressure.

-

Precision Sealing System Molding: We utilize multi-stage hot runner systems and precise temperature control technology to ensure one-time molding of drum thread openings and sealing surfaces, achieving dimensional accuracy in compliance with ISO standards and a leakage rate below 0.01%.

-

Efficient Production Solutions: Our innovatively designed conformal cooling system increases cooling efficiency by 35% and reduces the molding cycle to 90-120 seconds, significantly improving production efficiency.

Manufacturing Process and Quality Control

Advanced Manufacturing Equipment

Yige Mold is equipped with heavy-duty precision equipment, including large-scale gantry machining centers (worktable size 4000×2000mm), deep-hole drills (maximum machining depth 1500mm), and five-axis machining centers, ensuring the machining accuracy and efficiency of large molds.

Stringent Quality Management System

-

Material Inspection: All mold steels are sourced from premium suppliers such as Baosteel and Fushun Special Steel, with batch testing implemented to ensure stable material performance.

-

Process Control: We have established a digital manufacturing management system to monitor key parameters such as machining accuracy, heat treatment processes, and assembly clearances in real time.

-

Final Verification: Continuous 72-hour trial runs are conducted on large 800-2500 ton injection molding machines to verify mold stability and product qualification rates.

Technical Parameters and Performance Indicators

Mold Specifications

-

Applicable injection molding machine tonnage: 800-2500 tons

-

Mold size range: 1500×1500mm to 2500×2500mm

-

Mold weight: 8-25 tons

-

Number of cavities: 1-2 cavities (customizable according to customer requirements)

Product Performance Parameters

-

Drum body wall thickness: 1.8-3.5mm (adjustable)

-

Minimum roundness error: ≤0.3%

-

Sealing surface flatness: ≤0.05mm

-

Drop resistance height: ≥1.8m

-

Stacking load capacity: ≥1500kg

Professional Service Process

Requirement Analysis Phase (3-5 working days)

Our technical team conducts in-depth analysis of customer requirements, including:

-

Product usage environment (chemical compatibility, temperature range, etc.)

-

Production process requirements (automation level, production cycle, etc.)

-

Relevant industry standard certifications (UN certification, food-grade certification, etc.)

Design and Development Phase (25-30 working days)

-

3D modeling and structural design

-

Mold flow analysis and process optimization

-

Mold drawing review and confirmation

-

Material procurement and pre-treatment

Manufacturing and Debugging Phase (50-60 working days)

-

Precision machining and heat treatment

-

Component inspection and pre-assembly

-

Mold final assembly and debugging

-

Trial runs and process optimization

Delivery and After-Sales Service

-

Provide complete technical documentation package

-

On-site installation guidance and operation training

-

Regular maintenance reminders and technical support

-

Lifetime repair and modification services

Industry Application Cases

Chemical Industry Solution

Developed a 200L closed-head chemical drum mold for a multinational chemical enterprise, using special anti-corrosion steel and an enhanced sealing structure. The product passed UN certification and has been put into use at multiple production bases worldwide, with cumulative production exceeding 3 million units and a product qualification rate of 99.8%.

Food Industry Application

Customized a food-grade storage and transport drum mold for a well-known food enterprise, utilizing mirror polishing and non-toxic coating technology. The product complies with FDA standards and is widely used in the transportation of liquid foods such as edible oil and soy sauce.

Customized Service Case

Developed a square industrial drum mold for a special industry client, optimizing space utilization while maintaining standard performance, improving warehousing and transportation efficiency by 30%.

Five Reasons to Choose Yige Mold

-

Professional Experience: Twenty years of experience in plastic drum mold manufacturing, with over 1,000 successful cases.

-

Technical Strength: Possesses a provincial-level engineering technology center and more than 20 national patents.

-

Quality Assurance: Strict quality control system with a first-time product acceptance qualification rate of 98.5%.

-

Comprehensive Service: 7×24-hour technical support with a 48-hour emergency response time.

-

Cost-Effectiveness: Significant price advantages and shorter delivery times compared to imported molds.

Yige Mold is committed to providing high-quality plastic drum mold solutions for global customers. We have an experienced technical team and advanced production equipment, enabling us to offer customized services based on specific customer requirements and ensure that every mold meets the strictest industrial standards and usage demands.

From preliminary design to final delivery, we maintain close communication with customers throughout the process to ensure smooth project execution. Our goal is not only to provide a mold but also to offer complete production process solutions and technical support to our customers.