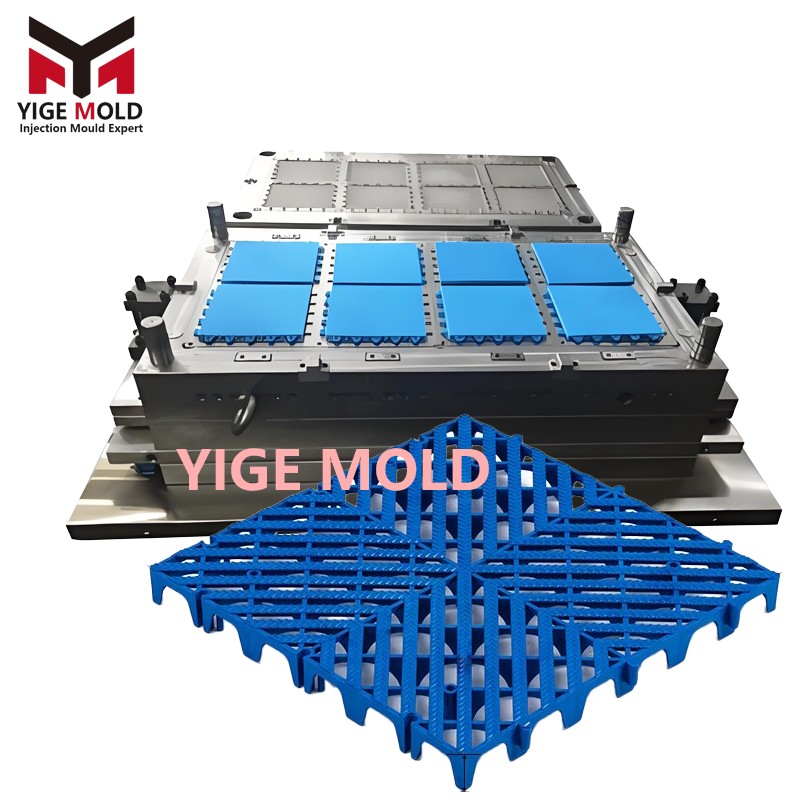

Platform Grating Mold

Platform Grating Mold: Professional Manufacturing Solution for Industrial Anti-Slip Platforms

Platform Grating Mold: Professional Manufacturing Solution for Industrial Anti-Slip Platforms

I. Product Definition and Market Positioning

Yige mold A Platform Grating Mold is a specialized injection molding mold used for producing grating plates for industrial platforms, walkways, operating platforms, and similar scenarios, belonging to the category of industrial-grade mold products. These molds are primarily used to manufacture plastic grating plates with high strength, high load-bearing capacity, and excellent anti-slip performance, meeting the safety operation requirements of industrial settings such as petroleum and chemical plants, wastewater treatment facilities, power equipment sites, and construction sites. With the continuous improvement of industrial safety standards, the requirements for platform gratings in terms of anti-slip properties, corrosion resistance, and load-bearing capacity are becoming increasingly stringent, placing higher demands on the mold's precision, strength, and durability.

II. Core Technical Features

1. High-Strength Structural Design

Platform grating molds utilize a multi-layer rib layout and cross-support structure to ensure stability during high-pressure injection molding. The mold cavity design fully considers stress distribution, incorporating R-angle transitions (≥3.0mm) in stress concentration areas to avoid mold cracking caused by stress concentration. The grating base employs a grid or channel framework. Through CAE analysis optimization of the rib layout, bending strength is improved by over 40%.

2. Anti-Slip Surface Design

The mold surface features a special anti-slip texture design. Through serrated flat steel or surface embossing processes, regular patterns of serrated protrusions or diamond patterns are formed on the grating surface. This design effectively increases the roughness of the contact surface and improves the friction coefficient. In dry conditions, the friction coefficient can reach 0.8, and it can remain above 0.6 under wet and slippery conditions, significantly reducing the incidence of slip-and-fall accidents.

3. Multi-Directional Core Pulling Mechanisms

For complex grating plate structures, the mold uses multi-directional core pulling designs such as "large slides + hydraulic cylinders" or "angled leader pins + large slides" to solve demolding challenges in undercut areas. The core pulling mechanisms are made from high-strength Cr12 mold steel, ensuring precision and durability under frequent operation.

4. Hot Runner System

To reduce molding clamp force and improve part quality, platform grating molds commonly employ a hot runner system. The hot runner design minimizes runner waste, improves material utilization, and shortens the molding cycle. The system is equipped with multiple hot nozzles to ensure uniform melt filling of the large cavity, preventing defects like short shots or weld lines.

5. Precision Guiding System

The mold uses precision leader pin and bushing guides with a fit clearance controlled within 0.02mm to ensure accurate mold closing. Leader pins are made from high-strength steel, surface-treated with nitriding (HV≥1000), offering excellent wear resistance and a service life exceeding 1 million cycles.

III. Materials and Process Standards

1. Mold Steel Selection

-

Cavity Material: Pre-hardened mold steels like S136H, NAK80, hardness HRC 38-42, offering excellent wear resistance and polishability.

-

Moving Components: Hot-work steels like SKD61, H13, hardness HRC 48-52, with high-temperature and fatigue resistance.

-

Mold Frame Material: S50C steel, providing sufficient strength and rigidity.

2. Surface Treatment Processes

-

Mirror Polishing: Cavity surfaces polished to Ra ≤ 0.05μm, ensuring part surface smoothness.

-

Nitriding Treatment: Mold surface hardness can reach HV ≥ 1000, significantly improving wear and corrosion resistance.

-

Hard Chrome Plating: Some moving components are hard chrome plated for further enhanced wear resistance.

3. Injection Molding Process Parameters

-

Barrel Temperature: 190-230°C for PP, 220-260°C for ABS.

-

Mold Temperature: 40-80°C, adjusted based on part wall thickness.

-

Injection Pressure: 70-120 MPa (high-pressure injection is required for heavy-duty gratings).

-

Holding Pressure: 60-80% of injection pressure.

-

Molding Cycle: Typically 3-5 minutes, depending on product size and wall thickness.

IV. Product Performance Advantages

1. High Load-Bearing Capacity

Grating plates produced by platform grating molds can bear loads of 3-5 tons/㎡, with some specially designed products reaching over 8 tons/㎡. Through optimized structural design and material selection, gratings remain stable and resistant to deformation even under full load, meeting the needs for the passage of heavy machinery and equipment.

2. Excellent Anti-Slip Performance

Using serrated flat steel or surface embossing designs, dense anti-slip contact points are formed on the grating surface. The friction coefficient can reach 0.8 in dry conditions and remain above 0.6 under wet and slippery conditions, effectively reducing the incidence of slip-and-fall accidents. Statistics show that workplaces using anti-slip grating can see a reduction in slip-and-fall accidents of over 70%.

3. Corrosion Resistance

The molds are made from corrosion-resistant materials, and the produced grating plates exhibit excellent resistance to acids, alkalis, and solvents. In corrosive environments such as chemical plants and wastewater treatment facilities, grating plates can maintain stable performance over long periods, with a service life of up to 15 years or more.

4. Lightweight and High Strength

Grating plates use a hollow grid structure, making them lightweight and high-strength, facilitating transportation and installation. Compared to traditional metal grating, the weight is reduced by over 50%, installation efficiency is improved by 60%, and construction time is halved.

5. Long Service Life

Platform grating molds are manufactured using premium steels and advanced processes, achieving a service life exceeding 1 million cycles. The produced grating plates have a service life of 15-20 years under normal usage conditions, with low maintenance costs.

V. Main Application Areas

1. Petroleum and Chemical Industry

Used for oil drilling platforms, chemical plant operating platforms, equipment maintenance walkways, etc., requiring grating plates with corrosion resistance, anti-slip properties, and high load-bearing capacity.

2. Wastewater Treatment Plants

Used for covers on wastewater treatment tanks, walkway platforms, maintenance access, etc., requiring grating plates resistant to acids/alkalis, anti-slip, and aging.

3. Power Equipment

Used for substation operating platforms, electrical room walkways, equipment maintenance platforms, etc., requiring grating plates with insulation, anti-slip properties, and high load-bearing capacity.

4. Construction Sites

Used for high-altitude work platforms, construction walkways, material storage platforms, etc., requiring grating plates with anti-slip properties, high load-bearing capacity, and easy installation.

5. Ports and Docks

Used for dock loading/unloading areas, ship decks, cargo storage yards, etc., requiring grating plates with corrosion resistance, anti-slip properties, and high load-bearing capacity.

VI. Production Process Flow

1. Mold Design and Manufacturing

CAD/CAM technology is used for mold design, with CAE analysis to optimize structure and ensure design rationality. Manufacturing utilizes advanced equipment like CNC milling machines, EDM machines, and wire-cutting machines, strictly controlling machining accuracy and surface quality.

2. Injection Molding

Dried plastic pellets are fed into the injection machine hopper, conveyed by the screw to the heated barrel for melting, and injected into the mold cavity under high pressure. Temperature, pressure, and time parameters are strictly controlled during injection to ensure stable part quality.

3. Cooling and Solidification

The melt cools and solidifies within the mold. Cooling time is determined by part wall thickness, typically 15-50 seconds. Mold temperature is controlled between 40-80°C to ensure proper cooling and dimensional stability.

4. Mold Opening and Demolding

The mold opens, and the part is ejected via the ejection system. Ejection speed and position must be carefully controlled during demolding to avoid part deformation or damage.

5. Post-Processing and Inspection

Parts undergo post-processing like deburring and trimming, followed by quality inspections including dimensional checks, visual inspection, and load-bearing tests to ensure products meet design requirements.

VII. Summary of Professional Manufacturing Key Points

The successful manufacturing of Platform Grating Molds relies on four core elements:

-

Precision Design: Accurate structural design based on CAE analysis ensures mold stability under high-pressure injection and precise part dimensions.

-

Quality Materials: Matching high-performance mold steels with quality plastic materials meets requirements for high strength and wear resistance.

-

Advanced Processes: Application of advanced technologies like hot runner systems and multi-directional core pulling mechanisms improves production efficiency and part quality.

-

Strict Quality Control: Full-process quality control from mold machining to product molding ensures products meet international standards.

Through systematic technical implementation and professional production management, it is possible to stably and efficiently produce products that comply with international standards and meet the diverse needs of the industrial platform market.

Platform Grating Mold: Professional Manufacturing Solution for Industrial Anti-Slip Platforms

Platform Grating Mold: Professional Manufacturing Solution for Industrial Anti-Slip Platforms

Cavity Material: Pre-hardened mold steels like S136H, NAK80, hardness HRC 38-42, offering excellent wear resistance and polishability.

Moving Components: Hot-work steels like SKD61, H13, hardness HRC 48-52, with high-temperature and fatigue resistance.

Mold Frame Material: S50C steel, providing sufficient strength and rigidity.

Mirror Polishing: Cavity surfaces polished to Ra ≤ 0.05μm, ensuring part surface smoothness.

Nitriding Treatment: Mold surface hardness can reach HV ≥ 1000, significantly improving wear and corrosion resistance.

Hard Chrome Plating: Some moving components are hard chrome plated for further enhanced wear resistance.

Barrel Temperature: 190-230°C for PP, 220-260°C for ABS.

Mold Temperature: 40-80°C, adjusted based on part wall thickness.

Injection Pressure: 70-120 MPa (high-pressure injection is required for heavy-duty gratings).

Holding Pressure: 60-80% of injection pressure.

Molding Cycle: Typically 3-5 minutes, depending on product size and wall thickness.

Precision Design: Accurate structural design based on CAE analysis ensures mold stability under high-pressure injection and precise part dimensions.

Quality Materials: Matching high-performance mold steels with quality plastic materials meets requirements for high strength and wear resistance.

Advanced Processes: Application of advanced technologies like hot runner systems and multi-directional core pulling mechanisms improves production efficiency and part quality.

Strict Quality Control: Full-process quality control from mold machining to product molding ensures products meet international standards.