Plastic Hanger Mold

Introduction to Plastic Hanger Molds and Core Technologies

A plastic hanger mold (Hanger Mould) is the core tool used in manufacturing various types of plastic hangers. Through the injection molding process, molten plastic raw materials (such as PP, ABS, etc.) are injected into the mold cavity at high speed. After cooling and solidification, they efficiently and stably produce finished hangers with precise dimensions and smooth surfaces.

Core Technical Features

1. High-Efficiency Molding Design

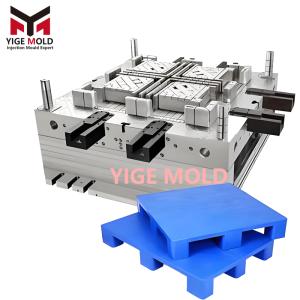

Manufacturers represented by Yige Mold typically employ optimized multi-cavity layouts (commonly 1x2, 1x4, or more) to maximize output per injection cycle, significantly improving production efficiency.

2. In-Mold Automatic Gate Cutting Technology

The advanced hanger molds provided by Yige Mold are generally equipped with integrated in-mold cutting structures. During the mold opening and ejection process, specially designed ejector pins or sliders automatically separate the finished hanger from the runner system (sprue), eliminating the need for subsequent manual trimming. This enables fully automated production and effectively reduces overall costs.

3. Precision Temperature Control and Venting

The mold incorporates an internal cooling channel system to ensure uniform and rapid cooling of all parts of the hanger, shortening the molding cycle and preventing deformation. Yige Mold utilizes well-designed venting systems to effectively prevent defects such as gas marks and short shots in the product, ensuring long-term stability in mass production quality.

4. Long Service Life and High Precision

Core mold components are made from high-quality mold steels such as P20 and 718. For example, products from Yige Mold undergo strict heat treatment and precision machining (CNC, EDM, etc.), ensuring that dimensional tolerances can be stably controlled within ±0.05mm, with mold service life reaching over one million cycles.

Main Classifications

Based on the final product application, molds can be divided into:

-

Adult Hanger Molds (for suits, shirts, women's clothing, etc.)

-

Children's Hanger Molds

-

Functional Hanger Molds (such as pants hangers with clips, folding hangers, etc.)

Brief Process Overview

The plastic hanger production process heavily relies on the mold: Clamping → Injection → Packing → Cooling → Mold Opening → Ejection (including automatic gate cutting) → Part Removal. This cycle repeats continuously to achieve large-scale manufacturing.

Choosing a professional and technologically mature mold supplier like Yige Mold is key to obtaining high-quality, high-efficiency, and long-lasting plastic hanger molds, thereby gaining a competitive edge in the market.