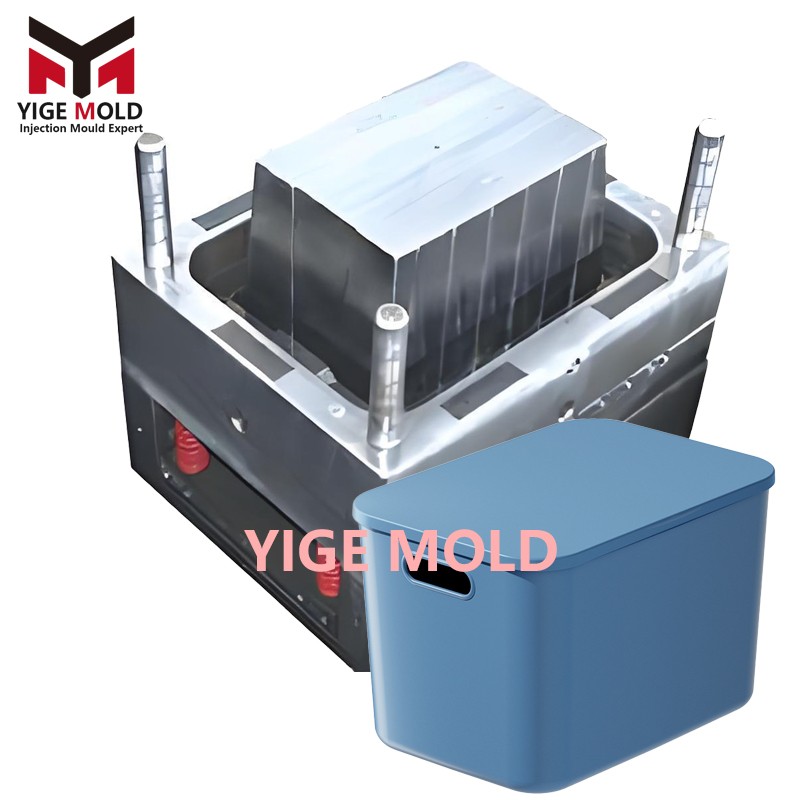

Toy Storage Box Mold

Yige Mold specializes in the R&D and manufacturing of toy storage box molds. Utilizing advanced mold technology, we efficiently transform plastic pellets (such as PP, PE, ABS) into structurally sound, safe, and durable storage containers. Our mold solutions help clients produce high-quality toy storage products that meet the organizational needs of households, kindergartens, and educational institutions, while complying with international safety standards for children's products.

Yige Mold Technical Advantages

1. Professional Design Team

-

Over 10 years of experience in designing molds for children's products

-

Proficient in various storage box structures: stackable, lidded, transparent, and more

-

Utilizes 3D simulation analysis to optimize mold structure and injection processes

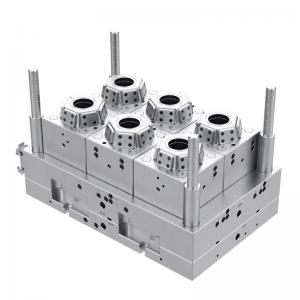

2. Precision Manufacturing Capabilities

-

Equipped with Swiss precision machining equipment

-

Strict tolerance control (±0.02mm)

-

Advanced surface treatment processes

Yige Mold Main Product Types

1. Stackable Storage Box Molds

-

Design Features: Patented buckle structure for stable stacking

-

Mold Characteristics: Yige's self-developed side-core pulling system

-

Customer Value: Increases space utilization and enhances product competitiveness

2. Safe and Eco-Friendly Storage Box Molds

-

Material Standards: Compliant with international safety standards such as EN71, ASTM F963

-

Structural Design: Fully rounded edges, no sharp corners causing injury risks

-

Yige Advantage: Deep collaboration with food-grade raw material suppliers

3. Multi-Functional Storage Box Molds

-

Modular Design: Adjustable internal partition system

-

Mold Characteristics: Quick-change insert technology

-

Production Flexibility: One mold produces multiple product variants

Yige Mold Manufacturing Process

Phase One: Design & Analysis

-

Requirement Communication: Deep understanding of the client's product positioning

-

Structural Design: 3D modeling by Yige's professional team

-

Mold Flow Analysis: Predicts and resolves potential issues in advance

Phase Two: Precision Machining

-

Material Selection: Recommends suitable steels (P20, 718H, etc.) based on production volume requirements

-

CNC Machining: High-precision CNC machine tool processing

-

Heat Treatment: Enhances mold lifespan and stability

Phase Three: Assembly & Debugging

-

Component Assembly: Professional technician team assembly

-

Trial Run Optimization: Debugging in Yige's trial run workshop

-

Sample Confirmation: Production begins after client approval

Yige Mold Quality Assurance System

1. Material Control

-

Premium Mold Steels: P20, 718H, etc., scientifically selected based on production needs

-

Raw Material Test Reports: Traceability for every batch

-

Lifespan Guarantee: Corresponding production cycle guarantees provided based on different steel grades

2. Process Inspection

-

CMM Inspection: 100% inspection of critical dimensions

-

Trial Run Report: Detailed debugging parameter records

-

Safety Testing: Simulates real-world child usage scenarios

3. After-Sales Service

-

Technical Training: Provides mold usage training for clients

-

Rapid Response: Technical support within 24 hours

-

Regular Maintenance: Establishes mold maintenance records

Six Reasons to Choose Yige Mold

-

Industry Focus: Deep expertise in the children's product mold sector, understanding specific safety requirements

-

Technical Leadership: Continuous R&D on new structures and production processes

-

Delivery Assurance: Standardized processes ensure on-time delivery

-

Cost Optimization: Rational design reduces client production costs

-

Consistent Quality: Strict control ensures consistent quality for every mold

-

Comprehensive Service: Full-process technical support from design to production

Yige Mold Steel Application Guide

P20 Mold Steel

-

Characteristics: Pre-hardened plastic mold steel, hardness HRC 28-32

-

Application Scenarios: Small to medium batch production, general-purpose toy storage box molds

-

Yige Application: Cost-effective mold solution with high value for money

718H Mold Steel

-

Characteristics: Pre-hardened high-strength mold steel, hardness HRC 33-38

-

Application Scenarios: Large batch production, high-precision molds with high surface finish requirements

-

Yige Application: High-end storage box molds ensuring long-term stable production

Cooperation Process

-

Requirement Consultation: Client provides product concept or sample

-

Solution Design: Yige provides mold design proposal and quotation

-

Contract Signing: Clarifies technical specifications and delivery standards

-

Mold Manufacturing: Fully transparent process with regular progress updates

-

Trial Run Acceptance: On-site or video acceptance by the client

-

Mass Production: Provides production parameter guidance and technical support

-

After-Sales Maintenance: Establishes a long-term cooperative relationship

Frequently Asked Questions

Q: What is the typical delivery time for a Yige Mold?

A: Depending on complexity, typically 25-45 days. We offer an expedited channel for urgent needs.

Q: How to choose between P20 and 718H steel?

A: P20 is suitable for small to medium batch production (typically 200k-500k cycles), while 718H is for large batch production (typically 500k+ cycles). Yige engineers will recommend the most suitable material based on your production volume and budget.

Q: How does Yige guarantee mold lifespan?

A: We recommend steel grades based on the client's expected production volume. Both P20 and 718H are sourced from premium suppliers to ensure stable material performance, and we provide a clear lifespan guarantee.

Q: Do you support small-batch orders?

A: Yes. We offer flexible modular design solutions to reduce production costs for small batches.

Q: Does Yige have successful case studies for reference?

A: We have collaborated with several well-known toy brands and can provide reference cases as needed (subject to a Non-Disclosure Agreement).