Drink Crate Mold

Drink Crate Mold: The Precision Core of High-Strength Logistics Circulation Systems

Drink Crate Mold: The Precision Core of High-Strength Logistics Circulation Systems

The product of a drink crate mold is far from an ordinary container—it is a standardized logistics unit designed for high-intensity, high-frequency cycles within the modern beverage supply chain. The core objective of its mold design and manufacturing is to ensure the product withstands hundreds or even thousands of cycles under extremely demanding conditions: robotic handling on automated filling lines, low-temperature shocks during cold-chain transport, frequent stacking and display at retail points, and return washing. This demands that the mold represents the ultimate integration of mechanical performance, dimensional stability, and production efficiency.

I. Structural Design: Engineering for "Circularity"

-

Impact and Fatigue Resistance Design

-

Grid Mechanics of the Crate Body: The grid structure of the crate walls is not merely perforated but follows a topology-optimized truss-style mechanical model. Each intersection is critical for stress calculation, ensuring deformation is controlled within millimeters when bearing the weight of a full load of bottles (often exceeding 20 kg). The mold must precisely form these ribs with graduated wall thickness—thicker at the base for bending resistance and tapered at the top for easy demolding.

-

Bottom Load-Bearing System: The bottom is designed with multiple sets of mutually supportive "crisscross" or "star-pattern" reinforcing ribs, integrally molded with heavy-duty stacking feet at the four corners. The feet often incorporate internal reinforcing ribs. The mold uses complex angled lifters and sliders to form these internal structures, ensuring stacking pressure is transferred vertically to prevent sidewall stress.

-

-

Automated Logistics Compatibility Design

-

Precision Locating Features: To interface with Automated Storage/Retrieval Systems (AS/RS) and robotic arms, the mold must form highly precise locating slots, guide ramps, or identification surfaces at specific positions on the crate (e.g., bottom edges, short sides). The dimensional tolerance for these features is typically within ±0.1mm to guarantee absolute accuracy for every automated pick-and-place operation.

-

Ergonomic and Reliable Handholds: The handhold (Hand Hole) shape balances ergonomics and mechanical gripping. The mold must form smooth, double-sided radii with full rounded edges to prevent injury and distribute lifting stress. Adequate backing support is designed behind them to prevent tearing after prolonged use.

-

II. Mold Engineering: Achieving Maximum Production Efficiency and Consistency

-

High Yield and Fast Cycling

-

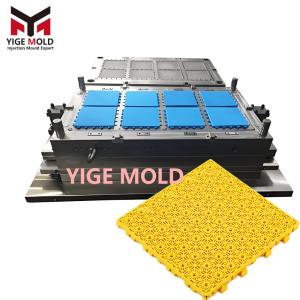

Family Mold and Multi-Cavity Strategies: To meet the massive demands of the beverage industry, molds often employ multi-cavity or family mold layouts (producing different parts, like crate and lid, in the same mold). This places extremely high demands on the balance of the hot runner system, requiring identical filling, packing, and cooling conditions in each cavity to eliminate weight and shrinkage variations between crates.

-

High-Pressure, High-Speed Molding: To maximize production rates, mold design must withstand very high injection pressure and speed (often >150 MPa). This requires a mold base with exceptional rigidity and specially reinforced guide pins/bushings to prevent "mold breathing" under sustained high pressure, thereby ensuring dimensional stability.

-

-

Long Service Life and Minimal Maintenance

-

Reinforcement Against Wear: Service life requirements for crate molds often exceed 1.5 million cycles. Wear-resistant inserts (e.g., powder metallurgy steel with hardness HRC 54-56) are used in high-wear areas like grid ribs. All moving components (sliders, lifters) are equipped with self-lubricating systems.

-

Efficient Conformal Cooling: The complex grid structure makes uniform cooling critical to prevent warpage and shorten cycle times. Molds widely adopt 3D-printed conformal cooling channels or special-shaped thermal conductive inserts to ensure heat is removed quickly and evenly, minimizing cycle times (achievable within 25-35 seconds).

-

III. Materials Science and Sustainability Adaptation

-

Adaptation to Dedicated Material Formulations

-

Mold design is optimized for copolymer polypropylene (PP), the dominant material. PP offers excellent fatigue and low-temperature impact resistance, but has relatively high shrinkage and pronounced orientation. The mold's cooling system and packing profile require specialized tuning to control the crate's dimensional stability across an environmental range of -25°C to 70°C.

-

For production using high percentages of Post-Consumer Recycled (PCR) material, the mold's runners and gates must be designed wider and smoother to accommodate potential flow variations and contaminants in the recycled content, while also enhancing the steel's corrosion resistance.

-

-

Lightweighting and Carbon Footprint

-

Through structural optimization and precise wall thickness control, modern molds enable individual crate weight to be reduced by 15-20% compared to a decade ago, directly reducing raw material consumption and transport carbon emissions while maintaining performance. The precision of the mold ensures this lightweighting does not come at the cost of strength.

-

IV. Quality Validation: Simulating a Lifetime of Harsh Use

Mold acceptance relies not just on first-article samples but must pass small-batch pilot production validation:

-

Dynamic Load Fatigue Testing: Simulating handling and drops (corner, edge, and flat) under full load.

-

High/Low-Temperature Cycle Testing: Alternating exposure between -30°C and 60°C environments to test material weatherability and dimensional recovery.

-

Automation Compatibility Testing: Thousands of pick, convey, and stack cycles on actual automated lines to verify the reliability of locating features.

Conclusion: The Silent Cornerstone of the Supply Chain

The drink crate mold is the physical cornerstone connecting the closed loop of beverage production, logistics, sales, and recycling. Its value lies not merely in manufacturing a box, but in shaping an efficient, reliable, and sustainable logistics circulation system. A top-tier crate mold is a high concentration of materials science, precision engineering, and supply chain management intelligence. It silently ensures that every bottle of beverage travels safely and efficiently from the production line to the consumer, ready to begin its next cycle.