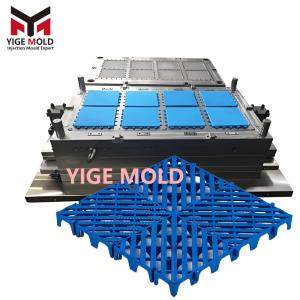

Air Cooler Mold

YiGe Molds - Professional Air Cooler Mold Manufacturer

YiGe Molds is a professional air cooler mold manufacturer, specializing in providing high-precision and high-efficiency injection mold solutions for the air cooler manufacturing industry. With over 20 years of experience in mold manufacturing, the company utilizes advanced CAD/CAM 3D design technology to ensure cavity precision reaches micrometer levels.

Product Advantages

YiGe Molds selects premium mold steels such as P20, 718, and S136, which undergo heat treatment processes including tempering, quenching, and nitriding to achieve hardness levels up to HRC 35-38. The mold lifespan can reach 500,000 to 2 million cycles. Equipped with optimized cooling channel systems, the molds utilize cold runner or hot runner technology combined with copper tube-aluminum fin heat exchangers to achieve rapid cooling and molding, significantly improving production efficiency.

Technical Capabilities

YiGe Molds employs advanced processing equipment such as CNC machining centers, high-speed milling machines, EDM, and wire cutting, strictly adhering to the ISO9001 quality management system. The molds support injection molding with various plastic materials, including ABS, PP, HDPE, PC, PVC, PA6, PA66, and PET. The number of mold cavities can be customized according to customer requirements, supporting configurations such as 1-out-1, 1-out-2, and more.

Service Commitment

YiGe Molds provides end-to-end services from design and manufacturing to debugging, with sample production cycles ranging from 35 to 85 days, a 1-year warranty, and lifelong maintenance. The company boasts a professional design team, offering technical support and rapid response to address various production challenges. Leveraging the advantages of large-scale production, YiGe provides customers with the most competitive prices.

YiGe Molds are widely used in industries such as home appliances, automotive, electronics, food, pharmaceuticals, chemicals, and textiles. They are particularly suitable for injection molding of products like household air cooler housings, industrial air cooler casings, and water-cooled air conditioner enclosures. For more information or to request a customized solution, please feel free to contact us.