Plastic stool mould

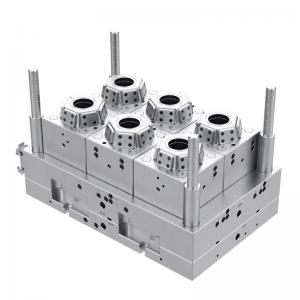

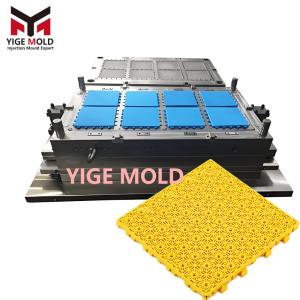

Yige mold In the production system of plastic stools, the design and processing quality of the molds directly determine the performance and production efficiency of the final products. The mold design begins with a thorough analysis of the structure, functional requirements, and material properties of the stool body. Through 3D modeling and mold flow simulation, the pouring system, cooling circuit, and ejection mechanism are precisely planned. Among them, the design of the flow channel needs to ensure the balanced filling of the plastic melt, the cooling waterway needs to meet the requirements of rapid and uniform heat dissipation, and the ejection structure must guarantee the complete ejection of the product without affecting functions such as stacking.

In the processing and manufacturing stage, the core components of the molds are made of high-hardness mold steel (such as P20, 718, etc.). The cavity milling is completed by a precise CNC machining center. For complex curved surfaces and fine structures, slow wire electrical discharge machining and electro-discharge machining are used to achieve the desired results. All mating surfaces need to be processed by a precision grinding machine to ensure the mating accuracy. Finally, through multiple rounds of mold testing and parameter adjustment, the molds reach a stable production state, ensuring that each molding cycle can produce plastic stools with precise dimensions and solid structure.

In the processing and manufacturing stage, the core components of the molds are made of high-hardness mold steel (such as P20, 718, etc.). The cavity milling is completed by a precise CNC machining center. For complex curved surfaces and fine structures, slow wire electrical discharge machining and electro-discharge machining are used to achieve the desired results. All mating surfaces need to be processed by a precision grinding machine to ensure the mating accuracy. Finally, through multiple rounds of mold testing and parameter adjustment, the molds reach a stable production state, ensuring that each molding cycle can produce plastic stools with precise dimensions and solid structure.

Write your message here and send it to us