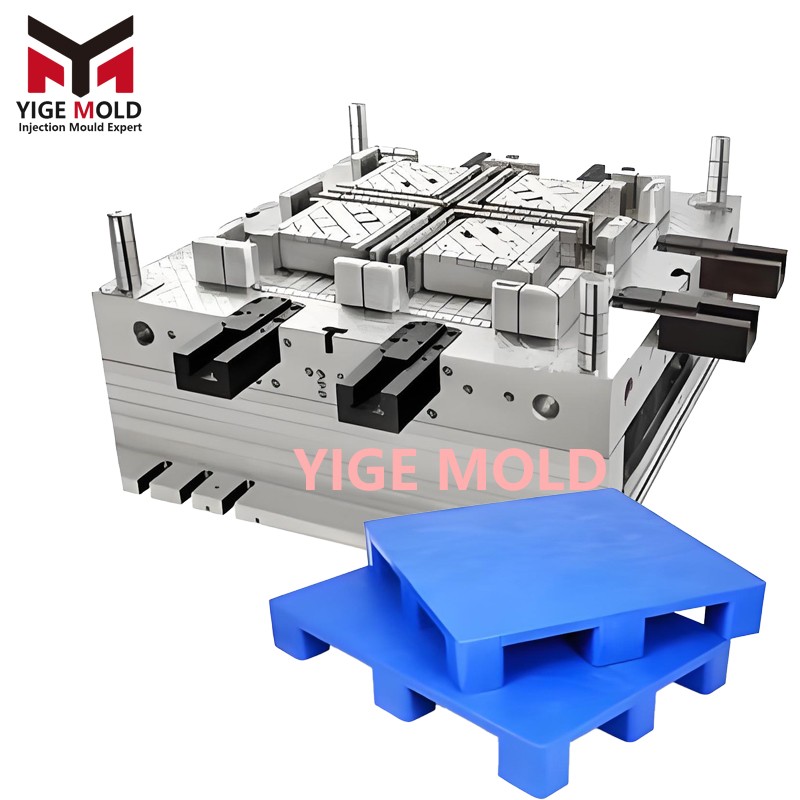

Pallet Injection Mold

Introduction to Pallet Injection Molds: Key Design and Manufacturing Points

Introduction to Pallet Injection Molds: Key Design and Manufacturing Points

Overview

Pallet injection molds are specialized tools used for producing standardized pallets that comply with international transportation specifications. These molds must be designed to meet the pallet size standards, load-bearing requirements, and material specifications of different countries and regions, ensuring the produced pallets are universally interchangeable within the global logistics system. As a professional manufacturer in this field, Yige Mold is committed to providing high-precision, long-lasting pallet injection mold solutions.

Key International Standard Specifications

1. Size Standards

-

European Standard Pallet: 800×1200mm (Mainstream in Europe)

-

American Standard Pallet: 1000×1200mm (Common in North America)

-

Japan/Korea Standard: 1100×1100mm (Parts of Asia)

-

Australian Standard: 1165×1165mm

2. Load-Bearing Requirements

-

Static Load: ≥1500kg

-

Dynamic Load: ≥500kg

-

Rack Load: ≥800kg (For rack usage)

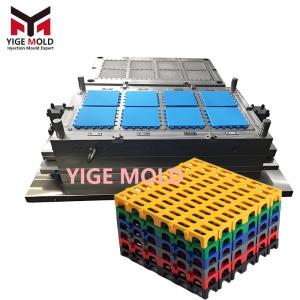

Design Features of Yige Injection Molds

Structural Design

-

Modular Design: Facilitates quick size module changes for multi-specification production

-

Optimized Rib Layout: Scientifically distributed rib structures enhance overall pallet strength

-

Standardized Interfaces: Ensure perfect compatibility with forklifts, racks, and other equipment

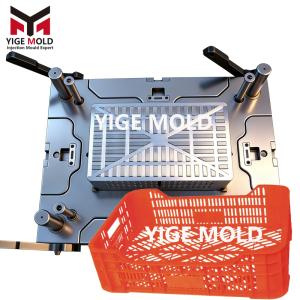

Materials and Processes

-

High-Quality Mold Steel: Yige Mold strictly selects premium-grade steels such as P20, 718, and S136

-

Surface Treatment: Utilizes advanced chrome plating and nitriding processes to significantly improve wear and corrosion resistance

-

Heat Treatment: Precise vacuum heat treatment technology ensures uniform and stable hardness within 48-52 HRC

Manufacturing Advantages of Yige Injection Molds

1. Precision Machining Technology

-

Utilizes imported five-axis CNC machining centers from Germany and Japan to ensure cavity accuracy within ±0.02mm

-

Employs EDM (Electrical Discharge Machining) for complex structures and fine details

-

Features a proprietary high-precision mold clamping system to guarantee absolute consistency across production batches

2. Intelligent Temperature Control System

-

Multi-layer, multi-circuit cooling design significantly reduces molding cycle times

-

Equipped with an intelligent temperature control module to precisely maintain mold surface temperature uniformity within ±1.5°C

-

Optimized venting system effectively minimizes defects like air bubbles and short shots

Quality Control System of Yige Injection Molds

Inspection Standards

-

Dimensional Tolerances: Strictly adhere to international standards such as ISO 6780

-

Weight Deviation: Achieves single-product weight error ≤1% through precision measurement

-

Balance Testing: Employs digital force measurement systems to ensure four-corner load-bearing variation ≤2.5%

Durability and Service

-

Extended Service Life: Yige Injection Molds can achieve over 1 million cycles under standard use and maintenance

-

Preventive Maintenance Plan: Provides customers with scientific periodic maintenance recommendations

-

Global Service Network: Yige Mold has established a rapid spare parts supply and technical support system to minimize customer downtime

Export Compatibility Assurance

Standards Compliance

Yige Mold has a deep understanding of global market differences. Every mold shipped ensures that the produced pallets meet the core standards of the target market:

-

Dimensions and tolerances comply with mainstream international logistics system requirements

-

Structural design meets load testing specifications of different regions

-

Material selection adapts to various industry needs such as food and chemicals

Packaging and Delivery

-

Professional Protection: Uses VCI anti-rust packaging and vacuum treatment to ensure zero corrosion during long-distance sea freight

-

Secure Transportation: Customized packaging frames prevent mold deformation during transit

-

Complete Documentation: Yige Mold provides detailed factory inspection reports, operation manuals, and material certificates to assist with customer customs clearance and acceptance

Core Value of Yige Injection Molds

Choosing Yige pallet injection molds delivers significant advantages:

-

Plug-and-Play: Molds are ready for stable production upon delivery, enabling quick response to overseas orders

-

Optimal Cost: High durability and low failure rates significantly reduce the per-pallet mold amortization cost

-

Consistent Quality: Excellent precision control ensures every pallet meets export standards

-

Seamless Integration: Produced pallets perfectly fit international containers, racks, and automated handling systems, enhancing supply chain efficiency

Conclusion

In the highly competitive global market, a reliable and professional pallet injection mold is the cornerstone of product competitiveness and supply chain stability. Yige Mold, with its profound technical expertise, precision manufacturing processes, and accurate grasp of international standards, provides customers with trustworthy pallet injection mold solutions. It serves as a powerful ally for expanding and consolidating your overseas market presence.