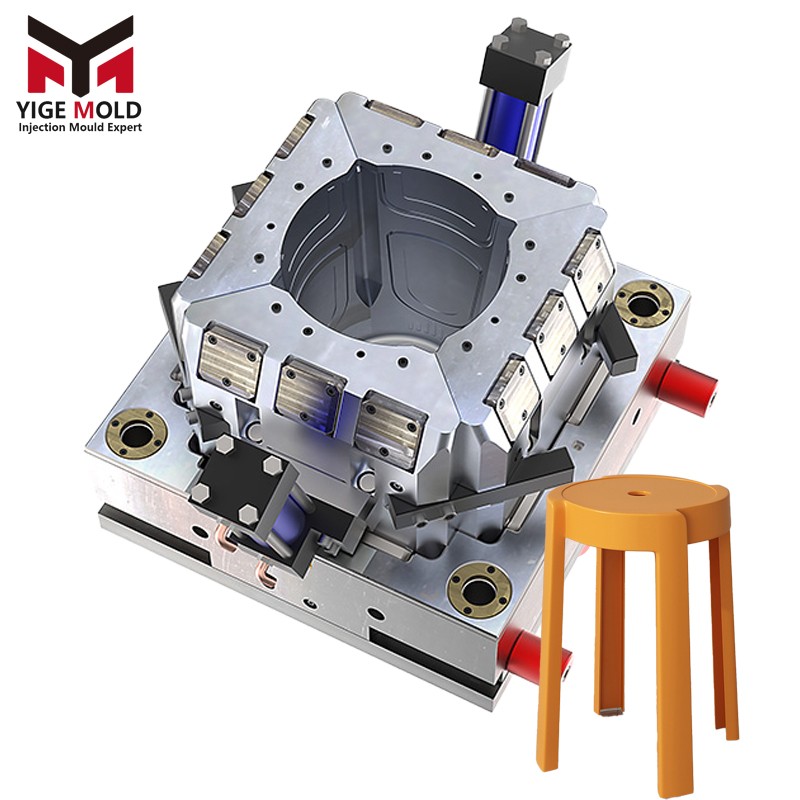

Injection plastic stool mold

Introduction to Injection Plastic Stool Mold

Introduction to Injection Plastic Stool Mold

1. Product Definition and Classification

The injection plastic stool mold is a specialized injection mold used specifically for manufacturing various types of plastic stools. It forms molten plastic by injecting it into the mold cavity, where it cools and solidifies to create the final stool product. This type of mold is an indispensable core production tool in the modern furniture manufacturing industry, widely used in household, office, outdoor leisure, and other fields.

Classification by Product Type:

-

Household Plastic Stool Mold: Primarily used for producing plastic stools for home use. Features simple structure, diverse size specifications, and high surface finish requirements.

-

Outdoor Portable Stool Mold: Specifically designed for outdoor leisure scenarios. The products are characterized by being lightweight, foldable, and highly weather-resistant.

-

Children's Plastic Stool Mold: Targeted for kindergartens, children's rooms, etc. Product design emphasizes safety, with rounded edges and environmentally compliant materials.

-

Office Stool Mold: Used for producing plastic stools for office environments. Products are generally larger in size with high structural strength requirements.

Classification by Mold Structure:

-

Two-Plate Mold Structure: Simple structure, low manufacturing cost, suitable for stool products with simple geometry.

-

Three-Plate Mold Structure: Suitable for molds requiring multi-point gating or for products with complex structures.

-

Hot Runner Mold: Utilizes a hot runner system to reduce runner waste and improve material utilization. Ideal for large-sized stool molds.

2. Technical Parameters and Specifications

Mold Steel Selection

The choice of steel for a stool mold directly impacts its service life and the quality of the final product. Commonly used mold steels include:

-

P20 Pre-Hardened Steel: Hardness 30-35 HRC, offers good machinability and wear resistance. Minimum service life: 300,000 cycles under normal use.

-

718 Pre-Hardened Steel: Hardness 32-36 HRC, superior wear and corrosion resistance compared to P20. Minimum service life: 500,000 cycles.

-

S136 Stainless Steel: Excellent corrosion resistance and mirror polishability, suitable for molds requiring high-gloss surface finishes.

-

H13 Hot Work Tool Steel: Hardness 48-52 HRC, good high-temperature resistance, suitable for die-casting molds or high-temperature injection molding applications.

Mold Precision Requirements

The machining precision of the stool mold directly determines the dimensional stability and appearance quality of the product. Key precision indicators include:

-

Cavity Dimensional Accuracy: Within ±0.05mm to ensure product dimensions meet design requirements.

-

Parting Surface Fit Accuracy: ≤0.02mm to prevent flash formation.

-

Surface Roughness: Cavity surface Ra ≤0.4μm to ensure a smooth product finish.

-

Guide Pin/Bushing Fit Accuracy: H7/g6 fit to ensure smooth mold opening and closing.

Mold Life Indicators

-

P20 Material Mold: Minimum 300,000 cycles under normal use, can exceed 500,000 cycles with proper maintenance.

-

718 Material Mold: Minimum 500,000 cycles, can reach up to 1,000,000 cycles.

-

S136 Material Mold: Minimum 800,000 cycles, suitable for high-demand products.

3. Core Elements of Mold Design

Parting Surface Design

The parting surface is a core aspect of mold design, directly affecting product demolding and appearance quality. The design principles for stool mold parting surfaces include:

-

Parting Line Location: Should be placed on non-cosmetic or hidden surfaces whenever possible to avoid affecting aesthetics.

-

Draft Angle: Set appropriately (typically 1°-3°) based on product height and material shrinkage to ensure smooth ejection.

-

Venting System: Designed to prevent defects like bubbles or burn marks. Vent depth is typically 0.02-0.05mm.

Gating System Design

The gating system is the channel for molten plastic to enter the cavity, directly affecting filling and appearance.

-

Gate Type: Selected (side gate, pin-point gate, submarine gate, etc.) based on product structure and cosmetic requirements. Stool molds often use multi-point gating for uniform filling.

-

Runner Design: Uses a balanced runner layout to ensure simultaneous cavity filling and prevent warpage. Runner cross-sections are typically circular or trapezoidal, sized according to product and material.

-

Cold Slug Well: Located at the end of the sprue to trap the initial cold material, preventing it from entering the cavity.

Cooling System Design

The cooling system is key to improving production efficiency. Proper design shortens cycle times and enhances quality.

-

Water Line Layout: Should be as close to the cavity surface as possible, using conformal cooling channels for efficiency. Spacing is typically 3-5 times the channel diameter.

-

Cooling Time Control: Determined based on wall thickness and material. Typically accounts for 60%-80% of the total cycle time for stools.

-

Temperature Control: Uses mold temperature controllers to ensure uniform cooling and reduce internal stress.

Ejection System Design

The ejection system removes the molded part from the mold. Design considers product geometry and ejection force.

-

Ejection Method: Chosen (ejector pins, stripper plate, air ejection, etc.) based on product shape. Stool molds typically use multiple ejector pins for stable demolding.

-

Ejector Placement: Pins should be located on non-cosmetic areas like ribs or bosses to avoid witness marks.

-

Ejection Stroke: Should be greater than the product height to ensure complete part removal.

4. Complete Manufacturing Process

Stage 1: Design and Planning

-

Requirement Analysis: Communicate with the client to clarify design requirements, dimensions, materials, etc.

-

Mold Structure Design: Use CAD/CAM software for 3D design, defining parting surfaces, gating, cooling, and ejection systems.

-

CAE Analysis: Use software like Moldflow for flow analysis to predict filling, cooling, warpage, and optimize design.

-

Drawing Output: Complete full set of design drawings: assembly, part, and electrode drawings.

Stage 2: Material Preparation

-

Steel Procurement: Purchase suitable mold steel per design, including mold base, core, cavity, slider materials.

-

Steel Pre-processing: Perform rough machining, heat treatment, tempering, etc., to improve material properties.

Stage 3: Precision Machining

-

CNC Machining: Use CNC milling machines and machining centers for roughing and semi-finishing of cavities and cores.

-

EDM (Electrical Discharge Machining): Use EDM for deep cavities and corners inaccessible to CNC.

-

Wire EDM: Used for precision holes like guide pin and ejector pin holes.

-

Finishing: Use grinders, engraving machines, etc., for final machining of cavities and cores to achieve design precision.

Stage 4: Heat Treatment and Surface Treatment

-

Heat Treatment: Quenching and tempering of core, cavity, and other key components to increase hardness and wear resistance.

-

Surface Treatment: Polishing, texturing, plating, etc., as per product requirements. High-gloss surfaces require mirror finish; textured surfaces must match design specifications.

Stage 5: Mold Assembly and Debugging

-

Component Assembly: Assemble all machined parts, including guide pins/bushings, ejection system, slider mechanisms.

-

Trial Run Verification: Conduct trial runs on an injection molding machine to verify molding results and product quality.

-

Mold Adjustment: Make necessary adjustments and optimizations based on trial run results to ensure products meet design requirements.

-

Final Acceptance: Deliver the mold after client acceptance.

5. Quality Control Standards

Dimensional Accuracy Control

-

Use CMM (Coordinate Measuring Machine) for full-dimensional inspection.

-

Critical dimensions CPK ≥ 1.33.

-

Uniform clearance in fitting areas, no interference.

Surface Quality Requirements

-

Cosmetic surfaces free of scratches, pits, or polishing marks.

-

Uniform texture for textured surfaces.

-

High-gloss surfaces achieving mirror finish (Ra ≤ 0.012μm).

Functional Testing

-

Smooth mold opening/closing without sticking.

-

Stable ejection system operation with accurate return.

-

No leaks in cooling system, flow rate meets design specs.

-

Continuous production stability test (minimum 500 cycles).

Durability Verification

-

Fatigue testing simulating long-term use.

-

Wear testing on critical components.

-

Maintenance interval assessment and schedule creation.

6. Detailed Application Areas

Household Furniture Sector

Plastic stools are widely used in modern homes due to their lightness, durability, and easy cleaning. Mold design focuses on aesthetics, structural stability, safety, and high surface finish requirements.

Commercial and Office Sector

Office stool molds need to consider functional designs like cable management, storage structures, and adjustability. They must also meet demands for high-volume production and product consistency.

Outdoor Leisure Sector

Outdoor stools require properties like weather resistance, UV stability, and temperature change tolerance. Mold design must account for material shrinkage and incorporate structural reinforcements.

Public Space Applications

Stools for schools, hospitals, airports, etc., have higher safety and durability requirements. Mold design considers special standards like rounded edges and fire-retardant materials.

Customization Needs

The market for customized stool molds is growing with increasing demand for personalization. Mold designs need to be flexible to quickly adapt to small-batch, multi-variety production.

7. Selection and Usage Considerations

Key Points for Mold Selection

-

Choose mold steel based on the intended product material.

-

Determine mold life grade based on production volume requirements.

-

Select mold type based on product structure complexity.

-

Consider the convenience of future maintenance and modifications.

Usage Notes

-

Operate the mold strictly according to procedures.

-

Perform regular cleaning and maintenance.

-

Use appropriate mold release agents and protective oils.

-

Record mold usage cycles and maintenance history.

Maintenance Requirements

-

Check the lubrication system each shift.

-

Inspect cooling water lines periodically.

-

Repair minor damage promptly.

-

Establish and maintain a mold maintenance file.

8. Economic Benefit Analysis

Investment Cost Composition

-

Mold Design Fee: 5-10% of total investment.

-

Material Cost: 30-40%.

-

Machining/Manufacturing Cost: 40-50%.

-

Trial Run and Debugging Cost: 5-10%.

Production Efficiency Indicators

-

Injection Cycle Time: Typically 60-180 seconds.

-

Daily Output: 400-1,200 pieces per single mold (estimates vary).

-

Material Utilization: Can exceed 95% for hot runner molds.

-

Energy Consumption: 15-30% reduction in energy per part.

Return on Investment (ROI) Analysis

-

Mold Payback Period: Typically 6-18 months.

-

Total Output Over Lifetime: Can reach hundreds of thousands of pieces.

-

Unit Cost Advantage: Significant in high-volume production.

-

Quality Stability: Reduces defect rates and improves product consistency.

Conclusion

As critical equipment in the plastics industry, the technical level of injection plastic stool molds directly impacts the quality, cost, and production efficiency of the final product. Every stage—from design and manufacturing to use and maintenance—requires professional expertise and strict management. With the continuous application of new materials and processes, the manufacturing standards for stool molds will keep improving, creating greater value for users. Choosing the right mold supplier and establishing long-term partnerships is vital for the sustainable development of manufacturing enterprises.