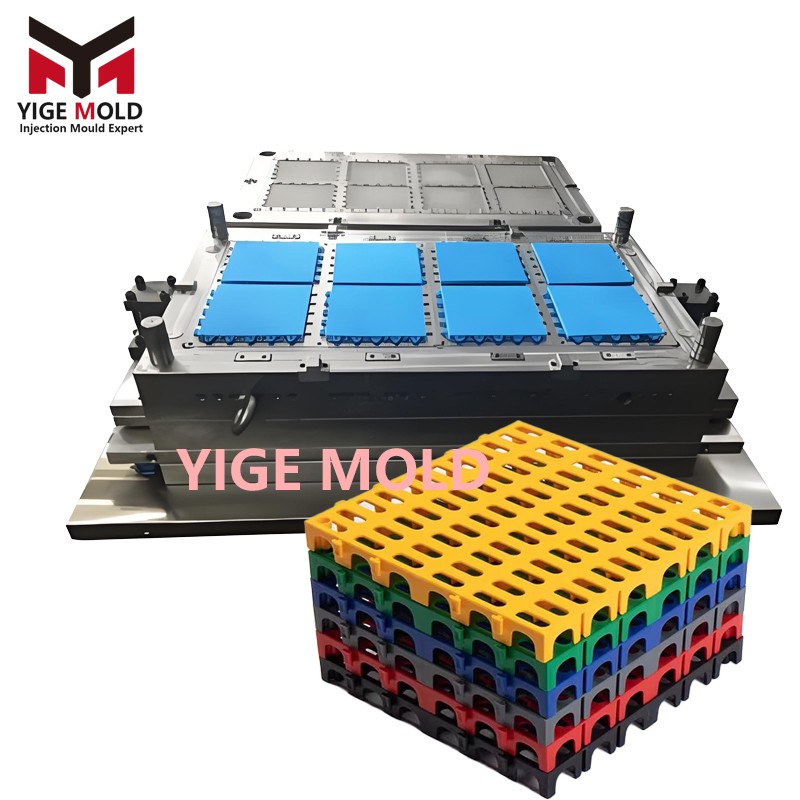

Plastic Grating Mold

In modern infrastructure and industrial systems, plastic grilles undertake multiple engineering tasks such as fluid management, structural support, and safety protection. The excellence of their performance begins at the manufacturing stage - the Plastic Grating Mold. yige Mold, as a professional solution provider in this field, positions the molds as a precise converter between engineering requirements and material properties. Through systematic design and manufacturing, it offers high-standard grille products with predictable performance and guaranteed lifespan for various application scenarios.

The R&D system of Yige Mold begins with a deep analysis of the end-user conditions. We not only consider the geometric shape of a single grille, but also optimize its functional attributes from the perspective of system integration. Through multi-physics field coupling simulation technology, we precisely balance the grille's opening rate, structural strength and fluid efficiency, ensuring that the product maintains optimal performance in complex loads and media environments. The mold surface is processed using Yige's proprietary micro-structure forming technology, which can build functional textures on the grille surface, achieving integrated integration of anti-slip, flow diversion, anti-fouling and other multiple characteristics. The mold body is made of high-performance special steel, combined with an intelligent temperature control system and high-precision guiding mechanism, ensuring micro-micron-level stability during long-term continuous production.

Yige Mold specializes in efficient molding solutions for complex structural engineering plastic products. We are particularly skilled in handling high-tech materials such as long glass fiber reinforced materials and high-temperature resistant polymers. Through optimized channel design and cooling systems, we solve industry problems such as the deformation of large thin-walled grids and uneven filling. Our mold system enables the integration of multiple functional structures in a single molding process, significantly improving product performance consistency and production efficiency.

The R&D system of Yige Mold begins with a deep analysis of the end-user conditions. We not only consider the geometric shape of a single grille, but also optimize its functional attributes from the perspective of system integration. Through multi-physics field coupling simulation technology, we precisely balance the grille's opening rate, structural strength and fluid efficiency, ensuring that the product maintains optimal performance in complex loads and media environments. The mold surface is processed using Yige's proprietary micro-structure forming technology, which can build functional textures on the grille surface, achieving integrated integration of anti-slip, flow diversion, anti-fouling and other multiple characteristics. The mold body is made of high-performance special steel, combined with an intelligent temperature control system and high-precision guiding mechanism, ensuring micro-micron-level stability during long-term continuous production.

Yige Mold specializes in efficient molding solutions for complex structural engineering plastic products. We are particularly skilled in handling high-tech materials such as long glass fiber reinforced materials and high-temperature resistant polymers. Through optimized channel design and cooling systems, we solve industry problems such as the deformation of large thin-walled grids and uneven filling. Our mold system enables the integration of multiple functional structures in a single molding process, significantly improving product performance consistency and production efficiency.

Write your message here and send it to us