Custom Plastic Hanger Mold

Custom Plastic Hanger Mold Introduction

Custom plastic hanger molds are specially designed and manufactured injection molding tools that meet the personalized needs of customers, enabling efficient production of various specifications and styles of plastic hanger products. Through custom services, enterprises can obtain exclusive mold solutions that align with their brand positioning, functional requirements, and production needs.

Custom Service Advantages

Personalized Design: Based on product drawings or physical samples provided by customers, Yige Mold's professional mold engineers conduct structural optimization and process analysis to ensure the molds meet production requirements. Various sizes, shapes, and functional hanger products can be customized, including adult hangers, children's hangers, non-slip hangers, folding hangers, and many other types.

Technical Capability Assurance: Yige Mold possesses over 10 years of design and manufacturing experience, enabling comprehensive analysis of mold structure and product structure, including key aspects such as mold draft angles, product surface shrinkage, gating system design, venting system design, and cooling system design.

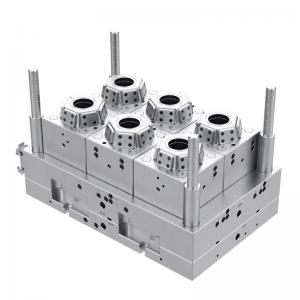

Cost Control: Through Yige Mold's rational design of mold cavity counts (such as 1x2, 1x4, or multi-cavity), production efficiency can be significantly improved, and unit costs reduced. Mold lifespan can exceed 1 million cycles, offering high cost-effectiveness for long-term use.

Custom Process

Requirements Communication Stage: Customers provide product design drawings or samples, specifying product specifications, material requirements, production quantities, and other relevant information. Yige Mold's technical department conducts feasibility analysis to determine the optimal design solution.

Mold Design Stage: Yige Mold utilizes professional software such as CAD, Pro/E, UG, and Solidworks for 3D modeling and conducts mold flow analysis to proactively prevent quality issues. The design cycle is typically completed within 3 days.

Manufacturing and Processing Stage: Yige Mold employs advanced equipment such as CNC machining centers, precision engraving machines, EDM machines, and wire-cutting machines for precision processing. Mold steel materials can be selected from high-quality options including 45#, P20, 718, 2738, 2316, H13, and S136, with processes such as quenching and tempering, vacuum heat treatment, and nitriding applied to enhance mold hardness and wear resistance.

Mold Trial and Validation Stage: After mold completion, trial production is conducted to inspect product dimensional accuracy, appearance quality, demolding performance, and other indicators. Yige Mold optimizes and adjusts based on trial results until customer satisfaction is achieved.

Delivery and Service Stage: Yige Mold provides complete sets of mold spare parts and maintenance documentation, establishing an after-sales service system to ensure long-term stable operation of the molds.

Technical Features

Efficient Molding System: Yige Mold employs a swirl-type multi-runner injection system to achieve uniform distribution of molten material, improving injection efficiency. The multi-cavity synchronous molding design enables simultaneous production of multiple hangers, significantly boosting output.

In-Mold Cutting Technology: Yige Mold integrates in-mold cutting and multi-ejector pin components that automatically separate finished products from runners during mold opening, eliminating the need for manual trimming and achieving fully automated production.

Precision Temperature Control System: Yige Mold's optimally designed cooling channels ensure uniform and rapid cooling of all hanger parts, shortening the molding cycle and preventing product deformation. A well-designed venting system avoids defects such as gas marks and short shots.

Long Lifespan Design: Yige Mold's mold core components use high-quality steel materials, undergoing three heat treatment processes (quenching and tempering, vacuum heat treatment at 42-46 HRC hardness, and 48-hour tempering), achieving surface hardness above HV850 and extended service life.

Application Fields

Custom plastic hanger molds are widely used in industries such as apparel retail, hotel supplies, home storage, supermarkets, and department stores, capable of producing hanger products of various specifications to meet usage requirements in different scenarios.

Choosing a professional custom mold service provider like Yige Mold enables enterprises to obtain full-process support from design to manufacturing, ensuring stable product quality, high production efficiency, and optimal cost control, thereby creating greater market competitiveness.