Inlet Pipe Fitting Mold

Comprehensive Guide to Water Inlet Pipe Fitting Molds: Design, Types, and Selection Considerations

Comprehensive Guide to Water Inlet Pipe Fitting Molds: Design, Types, and Selection Considerations

Core Definition and Technical Characteristics

Water inlet pipe fitting molds are specialized forming tools used for the mass production and high-precision manufacturing of inlet connection components in various pipeline systems. As critical sealing and connecting elements in fluid transport systems, these molds must meet stringent requirements for sealing performance, pressure resistance, and dimensional accuracy.

Main Product Types and Corresponding Mold Applications

1. Classification by Connection Method

-

Threaded Fitting Molds

-

Internal/External Threaded Fitting Injection Molds

-

Special Molds for Tapered Pipe Threads (R/Rc)

-

Special Molds for Parallel Threads (G)

-

-

Quick-Connect Fitting Molds

-

Snap-fit Quick-Connect Fitting Molds

-

Push-to-Connect Fitting Molds

-

Twist-lock Fitting Molds

-

-

Flanged Fitting Molds

-

Flat-face Flanged Fitting Molds

-

Loose Flanged Fitting Molds

-

2. Classification by Material and Process

-

Plastic Injection Molds

-

Special Molds for PP/PE/PVC/Nylon Inlet Pipe Fittings

-

High-temperature Resistant PPS/PEEK Fitting Molds

-

Food-grade Fitting Molds (Complying with FDA/NSF Standards)

-

-

Metal Forming Molds

-

Brass Fitting Die-casting Molds

-

Stainless Steel Fitting Precision Casting Molds

-

Forged Fitting Molds

-

Key Design Elements of Molds

Structural Design Considerations

-

Parting Line Design: Optimized for flash-free molding and easy demolding

-

Core-pulling Mechanism: Side core-pulling and angled-lifter systems for complex internal cavities

-

Venting System: Multi-layer venting to prevent air traps and ensure product density

-

Cooling Layout: Conformal cooling channels to ensure uniform cooling and reduce deformation

Precision Control Standards

-

Dimensional tolerance for critical sealing surfaces: ±0.02mm

-

Thread accuracy: Meeting 6H/6g grade standards

-

Concentricity: ≤0.05mm (ensuring sealing effectiveness)

-

Surface roughness: Ra ≤0.8μm (sealing surface areas)

Production Technology and Processes

Injection Molding Process Parameters

-

Injection pressure: 80-120MPa (adjusted based on material)

-

Mold temperature control: ±2°C precision (40-60°C for PP, 80-100°C for POM)

-

Cycle time: 15-45 seconds (depending on fitting size and wall thickness)

-

Holding pressure profile: Multi-stage holding pressure to ensure dimensional stability

Quality Inspection Items

-

Pressure testing: 1.5x working pressure held for 5 minutes with no leakage

-

Full dimensional inspection: 100% inspection of critical dimensions

-

Sealing surface inspection: Blue-light 3D scanning for sealing surface flatness

-

Material certification: Material property reports for each batch of raw material

Application Fields

1. Household Applications

-

Washing machine/dishwasher inlet fitting molds

-

Water purifier pipe connector molds

-

Bathroom equipment water inlet accessory molds

2. Industrial Applications

-

Cooling system pipe fitting molds

-

Hydraulic system quick-connect fitting molds

-

Chemical fluid transfer fitting molds

Mold Selection and Maintenance

Selection Considerations

-

Production Volume: <100,000 pieces: choose simple molds; >500,000 pieces: choose hard molds

-

Material Characteristics: Corrosive materials require corrosion-resistant steels like S136/DIN1.2316

-

Automation Level: Requirements for automated unscrewing, automatic gate cutting, etc.

-

Certification Requirements: NSF certification for potable water contact applications

Maintenance Guidelines

-

Daily maintenance: Cleaning and lubrication of moving parts

-

Weekly inspection: Check wear on sliders and angled lifters

-

Monthly maintenance: Inspect cooling channels for blockages

-

Quarterly overhaul: Complete disassembly inspection, polishing, and replacement of wear parts

Cost-Benefit Analysis

Mold Investment Return

-

Small fitting molds (single cavity): 80,000-150,000 RMB

-

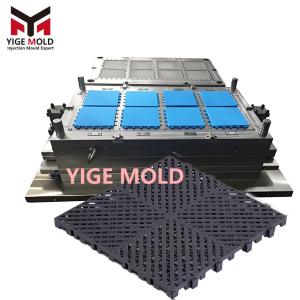

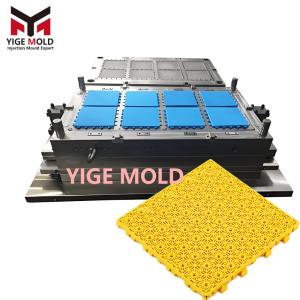

Medium multi-cavity molds (4-8 cavities): 200,000-400,000 RMB

-

Large automated molds (16-32 cavities): 500,000+ RMB

Production Efficiency Indicators

-

Single-cavity molds: 2,000-4,000 pieces/day

-

8-cavity molds: 15,000-25,000 pieces/day

-

32-cavity fully automated molds: 60,000-100,000 pieces/day

Conclusion

Selecting professional water inlet pipe fitting molds requires not only considering initial investment costs but also comprehensively evaluating mold lifespan, production efficiency, quality stability, and technical adaptability. With the development of materials science and manufacturing technologies, modern water inlet fitting molds are evolving towards higher precision, longer lifespan, and increased intelligence. Users are advised to have in-depth communication with experienced mold manufacturers during selection, taking into account the comprehensive lifecycle costs and benefits of the product.