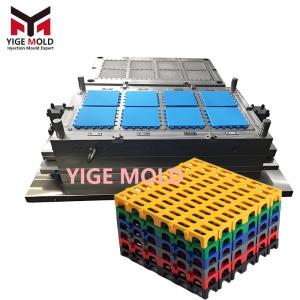

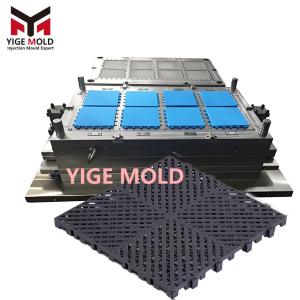

Pail mold

Yige Molds: Precision Manufacturing Experts in Pail Molds

Yige Molds: Precision Manufacturing Experts in Pail Molds

Yige Molds is a high-tech enterprise specializing in the design and manufacturing of pail molds, with over 20 years of industry experience. The company focuses on providing high-quality pail mold solutions for the chemical, food, pharmaceutical, and other industries. With advanced technical capabilities and a comprehensive service system, Yige Molds has become a leading enterprise in the domestic pail mold field.

Core Technical Advantages

High-Precision Hot Runner System

Yige Molds employs multi-point hot runner technology to ensure uniform filling of the molten plastic into the cavity, preventing defects such as shrinkage and warping in the product. The mold cavity surface undergoes mirror polishing, achieving a surface smoothness of up to Ra0.8μm, ensuring smooth demolding and excellent appearance quality. The hot runner system enables uniform filling of molten plastic through precise temperature control and timing. The runner layout is optimized according to the product's structural characteristics to avoid weld lines in stress-bearing areas, ensuring product structural strength.

Long-Life Design Philosophy

Core components of Yige Molds are made from high-quality imported mold steels such as 718H, S136, and NAK80. After vacuum heat treatment and cryogenic treatment, the hardness can reach HRC48-52, with a service life exceeding 1 million cycles. Guide pillars and bushings adopt an oil-free lubrication design, reducing maintenance frequency and lowering operational costs for enterprises. Material selection is based on a comprehensive consideration of mold service life, injection product requirements, and costs to ensure optimal cost-effectiveness.

Efficient Cooling and Venting Systems

The cooling system directly impacts production efficiency and product quality. Yige Molds utilizes a multi-circuit cooling system, with independent cooling channels for the core and cavity to ensure uniform cooling. Cooling channels are designed in a spiral or baffle style to improve cooling efficiency and shorten the molding cycle. The venting system includes venting slots at the parting line, core inserts, sliders, and other locations, with slot depth controlled at 0.03–0.05mm and width at 8–10mm, preventing defects such as burning or short shots in the product.

Production Process Flow

Mold Design Stage

The design process at Yige Molds includes multiple stages such as product mapping, 3D modeling, and mold structure design. First, the product is measured, and 2D engineering drawings are created. Then, software such as CAD and UG is used for 3D modeling. Key parameters such as parting line location, cavity quantity, and gate type are determined based on the product's structural characteristics. Mold design must consider factors such as the product's usage environment, load-bearing requirements, and sealing performance to ensure the mold meets production requirements.

Processing and Manufacturing Stage

Yige Molds employs advanced equipment such as five-axis CNC milling machines, precision grinders, and slow wire EDM. Main forming parts like cavities and cores are roughed and finished using five-axis machining centers, achieving machining accuracy of ±0.01mm. Standard parts such as guide pillars, bushings, and ejector pins are processed using precision grinders, with fit clearance controlled within 0.005–0.01mm to ensure smooth movement. For areas difficult to mill, such as deep cavities and narrow slots, electrical discharge machining (EDM) technology is used, achieving machining accuracy of ±0.003mm.

Assembly and Debugging Stage

Yige Molds uses precision measuring instruments during assembly to ensure the fit accuracy of all components. Guide pillars and bushings adopt an oil-free lubrication design to reduce maintenance frequency. The ejection system uses nitrogen springs or mechanical springs to ensure stable and reliable ejection. The cooling system undergoes water pressure testing to ensure no leakage. During trial molding, injection process parameters, including injection speed, holding pressure, holding time, and mold temperature, need to be adjusted. Product dimensions, appearance quality, and structural strength are verified through trial molding.

Material Selection and Performance Requirements

Mold Material Selection

Core components of Yige Molds require mold steel materials with excellent wear resistance, corrosion resistance, and thermal stability. Commonly used materials include 718H, S136, and NAK80. 718H material offers good polishing performance and wear resistance, making it suitable for main forming parts such as cavities and cores. S136 material has excellent corrosion resistance, making it suitable for producing transparent or food-grade products. NAK80 material features high hardness and good wear resistance, making it ideal for moving parts such as sliders and lifters.

Material Performance Requirements

Yige Molds materials must meet the following performance requirements: wear resistance, strength and toughness, thermal stability, corrosion resistance, good thermal conductivity, and dimensional stability. Wear resistance is one of the most fundamental and important properties of molds. The surface hardness of the mold cavity should be higher than that of the workpiece material, typically 30–50HB higher. For molds operating in high-temperature environments, materials must have high tempering resistance to maintain high hardness and strength at working temperatures.

Application Areas

Chemical Industry

Yige Molds is most widely used in the chemical industry, primarily for producing packaging containers for chemical raw materials, coatings, paints, and other products. The chemical industry has high requirements for pail sealing, corrosion resistance, and load-bearing capacity. Products must pass strict drop and sealing tests.

Food Industry

The food industry has stringent hygiene and safety requirements for pails, and products must meet food-grade standards. Food packaging containers produced by Yige Molds must have excellent sealing performance, oil resistance, and ease of cleaning.

Pharmaceutical Industry

The pharmaceutical industry has extremely high requirements for pail cleanliness, sealing, and impact resistance, and products must comply with GMP standards. Pharmaceutical packaging containers produced by Yige Molds must have excellent moisture-proof, oxidation-resistant, and contamination-resistant properties.

Yige Molds Technical Advantages

High-Efficiency Production Capacity

Yige Molds adopts quick mold change systems, combined with robotic automatic part removal, to achieve fully automated production. A single mold can achieve a daily output of 2,000–3,000 pieces, meeting the demands of large-scale logistics packaging. The mold design process fully considers the product's usage environment and performance requirements, such as compressive strength and durability, ensuring stable product quality under high-speed production conditions.

Product Quality Control

Yige Molds has established a comprehensive quality management system, with strict inspections conducted at every stage from raw material procurement to finished product shipment. The company is equipped with precision inspection equipment such as coordinate measuring machines and video measuring systems to ensure mold accuracy meets design requirements, providing customers with high-quality mold products. Through strict process control and quality management, products produced by Yige Molds achieve dimensional accuracy of ±0.1mm and mirror-like surface quality.

Technological Innovation Capability

Yige Molds holds multiple patents in areas such as hot runner systems, cooling systems, and venting systems. Adopting a modular design philosophy, the company can quickly customize pail molds of different specifications based on customer requirements, shortening delivery cycles and reducing customer costs. The company has a professional technical team capable of providing value-added services such as technical consultation, mold maintenance, and process optimization, helping customers improve production efficiency and reduce operational costs.

Service Philosophy

Yige Molds consistently adheres to a customer-centric approach, providing comprehensive pre-sales, in-sales, and after-sales services. The company has a professional technical team capable of providing value-added services such as technical consultation, mold maintenance, and process optimization, helping customers improve production efficiency and reduce operational costs. Yige Molds upholds the business philosophy of "quality first, customer foremost," committed to providing customers with high-quality mold products and excellent services, growing together with customers, and creating brilliance.

Through the comprehensive technical introduction above, it is evident that as a core equipment supplier for modern industrial packaging, Yige Molds' design and manufacturing level directly determines product quality and production efficiency. With continuous technological advancements and growing market demand, Yige Molds will embrace broader development prospects, providing more high-quality packaging solutions for industries such as chemicals, food, and pharmaceuticals.