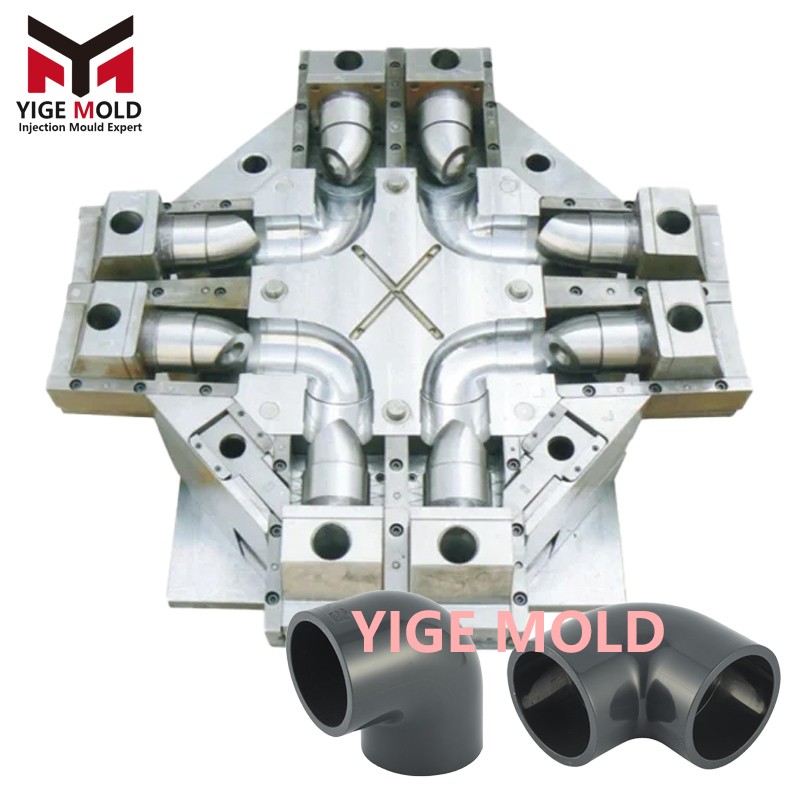

90-degree water inlet connector mold

90-Degree Water Inlet Fitting Mold - Yige Molds Professional Injection Molding Solution

90-Degree Water Inlet Fitting Mold - Yige Molds Professional Injection Molding Solution

I. Product Overview

The 90-degree water inlet fitting mold is specialized mold equipment used for manufacturing various types of 90-degree elbow fittings, employing injection molding processes to produce structurally stable, user-friendly pipe fitting products. 90-degree water inlet fittings feature lightweight construction, high strength, corrosion resistance, and easy cleaning, making them widely applicable in bathroom fixtures, pipeline connections, industrial fluid transportation, and other fields.

II. Core Design Features

1. Structural Design Optimization

90-Degree Elbow Structure: Utilizes right-angle elbow design to ensure smooth fluid directional change and reduce flow resistance. The mold incorporates slider side core-pulling mechanisms, achieving lateral parting and core-pulling through angled guide pins to ensure complete 90-degree elbow molding.

Sealing Structure Design: Both ends of the fitting incorporate sealing grooves for installing sealing rings, ensuring leak-free and airtight connections. Sealing grooves are precision-machined with surface roughness reaching Ra≤1.6μm.

Threaded Connection Design: One end features internal or external threads compatible with standard pipe fittings. Thread precision meets MT8 standards, ensuring secure and reliable connections.

2. Material Selection

Mold Steel: Uses high-quality mold steels (such as P20, 718H, 2738) with cavity accuracy controlled within ±0.03mm, ensuring stable structure and no deformation or cracking after fitting formation.

Plastic Material: Compatible with engineering plastics including ABS, Nylon 66+glass fiber reinforced, PP. Nylon 66+50% glass fiber reinforced material offers excellent mechanical properties, impact resistance, and wear resistance, suitable for high-pressure water flow environments.

Surface Treatment: Cavity surfaces undergo chrome plating or PVD coating treatment, achieving roughness of Ra≤1.6μm, enhancing product surface finish.

3. Functional Configuration

Quick Connection System: Uses compression or threaded connection methods for fast installation, reducing connection time. Some models support push-to-connect installation requiring no tools.

Leak Prevention Design: Integrated sealing rings with temperature resistance range of -40℃ to +80℃ and pressure resistance up to 3.0MPa, ensuring long-term leak-free operation.

Compatibility Design: Product specifications are compatible with international brand standards including HASCO, DME, MISUMI, STAUBLI, NITTO, allowing use with original equipment parts.

III. Technical Advantages

1. High-Precision Molding

Cavity Accuracy: Uses five-axis machining centers for precision processing, with cavity accuracy controlled within ±0.02mm. High-precision mold production ensures accurate product dimensions and smooth surfaces.

Thread Precision: Thread cores use precision EDM machining, achieving MT8 thread precision standards, ensuring perfect fit with standard pipe fittings.

Positioning Accuracy: Positioning slot dimensional accuracy reaches ±0.1mm, ensuring seamless integration with automated logistics equipment.

2. Efficient Cooling System

Zoned Temperature Control: Uses zoned temperature control and efficient cooling systems, maintaining cavity temperature differences ≤±2°C. Cooling system adopts conformal cooling technology, using 3D printing to create cooling channels, improving cooling efficiency by approximately 30%.

Cooling Uniformity: Water channel spacing controlled at 20-30mm ensures uniform cooling of large structures and prevents warping deformation. Cooling circuits use direct circulation design with symmetrical arrangement in upper and lower molds, improving cooling uniformity.

3. Material Compatibility

Mold Materials: Mold materials use high-quality mold steels such as P20, 718H, 2738, with hardness controlled between HRC33-62. High-frequency friction areas like sliders and core pins use tungsten steel inserts with surface nitriding treatment, hardness reaching above HV900.

Plastic Materials: Compatible with multiple engineering plastics including ABS, Nylon 66+glass fiber reinforced, PP, HDPE. Nylon 66+50% glass fiber reinforced material offers excellent mechanical properties, high tensile strength, and good corrosion resistance.

4. Structural System Optimization

Multi-point Synchronized Ejection System: Ejection pin density at least 2 per 100cm², ensuring smooth demolding of large products. Ejection mechanism uses pusher pin+slider combination, with specialized ejection mechanisms designed for fitting undercut structures.

Optimized Exhaust System: Vent hole dimensions set at 0.03-0.05mm, preventing defects like bubbles and shrinkage porosity. Exhaust slots designed near parting surfaces utilize parting surface gaps for natural exhaust.

"Avoidance Layout" Parting Surface Design: Adjusts parting lines from stress areas to non-stress areas, avoiding flash residue. Parting surfaces use three-plate structure, achieving three-stage sequential parting.

IV. Mold Manufacturing Process

1. Mold Structure Design

Cavity Quantity: Uses one-mold-two-cavity or one-mold-four-cavity designs based on production batch requirements. Cavity arrangement uses symmetrical layout to ensure uniform melt filling.

Gating System: Uses pinpoint gates with gate locations set on raised annular bands, avoiding visible gate marks on outer cylindrical surfaces. Gating system uses hot runner technology, reducing material waste by 15%-20%.

Cooling System: Cooling circuits use direct circulation design with symmetrical arrangement in upper and lower molds. Baffle plates added in cooling circuits improve cooling uniformity.

2. Core-Pulling Mechanism Design

Angled Guide Pin Side Core-Pulling: Uses angled guide pin lateral parting and core-pulling mechanisms with core-pulling distance of 27.5mm, guide pin inclination angle of 18°, and working length of 113mm. Sliders use spring return with wedge block locking.

Automatic Thread Demolding Mechanism: For internal threaded fittings, uses gear transmission mechanism+core-pulling hydraulic cylinder automatic thread demolding. Thread cores rotate while moving linearly with core-pulling hydraulic cylinder, avoiding thread damage and deformation.

Slider Positioning: Uses tapered hole positioning, with positioning inner holes and bosses designed on thread-side core and smooth-hole-side core end faces respectively, ensuring both-side core concentricity and guaranteeing plastic part inner hole coaxiality.

3. Processing Technology

CNC Machining: Uses five-axis machining centers for precision processing, cavity accuracy ±0.02mm. Key components use slow wire EDM machining with accuracy reaching ±0.005mm.

EDM Processing: Precision EDM machining achieves complex curved surface formation, particularly precision machining of thread cores and sealing grooves.

Precision Polishing: Mirror polishing treatment achieves surface finish of Ra≤0.8μm, ensuring product appearance quality.

V. Molded Product Performance

1. Physical Performance

Mechanical Properties: Molded 90-degree water inlet fittings are impact-resistant and aging-resistant, passing high-pressure testing. Nylon 66+50% glass fiber reinforced material has high tensile strength with pressure resistance up to 3.0MPa.

Corrosion Resistance: Products have good corrosion resistance, suitable for long-term use in humid environments, resistant to acids, alkalis, and other chemical media.

Temperature Adaptability: Can operate long-term in conditions from -40℃ to +80℃, adapting to various harsh climate conditions.

2. Usage Performance

Sealing Performance: Integrated sealing rings ensure leak-free and airtight connections. Sealing rings withstand temperatures of 150℃ (rubber material) or 250℃ (fluorocarbon rings).

Connection Convenience: Uses quick connector design allowing installation and disassembly without tools, improving work efficiency.

Service Life: Products have long service life, with sealing rings replaced free of charge within 2 years if worn (old-for-new exchange).

3. Specification Customization

Specification Range: Supports multiple specification customizations, pipe diameters from 1/4 inch to 2.5 inches, thread specifications including PT1/8, PT1/4, PT3/8, PT1/2, etc.

Function Configuration: Can integrate personalized designs like classification marking slots, pedal linkage structures, movable wheel positions.

Application Scenarios: Meets usage requirements for different scenarios including households, offices, industries, and municipal engineering.

VI. Yige Molds Service Advantages

1. Technical Expertise

Professional Team: Yige Molds has 10 years of injection mold manufacturing experience, with professional teams providing customized solutions. Engineering teams can provide complete mold design solutions within 14 working days based on specific customer requirements.

Advanced Software: Uses CAD/CAM software for 3D modeling, combined with Moldflow molding analysis technology, simulating parameters like melt flow, filling pressure, and shrinkage deformation in advance, optimizing mold design.

Process Innovation: Adopts advanced processes like hot runner technology and conformal cooling technology to enhance mold performance and product quality.

2. Quality Assurance

Strict Inspection: Each mold undergoes strict quality inspection and trial verification, with three-coordinate measurement of grid dimensional tolerances ±0.15mm. Mold key components use slow wire EDM machining with accuracy reaching ±0.005mm.

Lifespan Guarantee: Mold lifespan exceeds 800,000 cycles, product dimensional tolerances controlled within ±0.1mm. Surface finish Ra≤0.08μm ensures stable batch-to-batch product quality.

Performance Testing: Products undergo multiple performance verifications including high-pressure testing, corrosion resistance testing, temperature adaptability testing, ensuring safe and reliable use.

3. After-sales Service

Technical Support: Yige Molds provides 24-hour technical support teams to solve various production problems. Common spare parts delivered within 48 hours, minimizing customer downtime losses.

Mold Management: Establishes mold asset management platforms allowing customers to view mold usage status, maintenance records, and remaining lifespan predictions online, achieving full lifecycle mold management.

Renovation Services: When molds reach service life, provides recycling and renovation services, restoring mold performance to over 80% by replacing key components and repairing worn parts, reducing customer costs.

4. Cost Advantage

Mass Production: Through mass production and optimized processes, provides customers with the most competitive prices. Implements standardized and customized mold development model, establishing comprehensive mold standard parts library covering mold bases, ejector pins, guide pillars, bushings, etc.

Material Optimization: Optimized gating system using hot runner technology reduces material waste by 15%-20% compared to traditional cold runners. Improved cooling system design using variable frequency pumps to regulate cooling water flow reduces energy consumption by 30%.

Efficiency Improvement: Through automated equipment and intelligent management systems, improves production efficiency, shortens delivery cycles, and reduces comprehensive costs.

VII. Mold Maintenance

1. Daily Maintenance

Moving Part Lubrication: Regularly lubricates moving parts like ejector pins, sliders, guide pillars, and bushings to maintain good lubrication.

Mold Surface Cleaning: After each production run, uses clean cloths to wipe mold surfaces, removing dust, oil stains, and plastic residues.

Cooling System Inspection: Checks whether mold cooling water channels are clear and whether leaks exist.

2. Regular Maintenance

Exhaust Slot Cleaning: Regularly cleans exhaust slots to prevent defects like bubbles and shrinkage porosity.

Wear Area Correction: Regularly inspects mold wear conditions, timely correcting damaged and worn areas to ensure mold accuracy meets requirements.

Surface Treatment: Regularly polishes cavity surfaces to maintain surface finish.

3. Appearance Maintenance

Rust Prevention: Applies paint to mold base exteriors to prevent rust. When removing molds, applies anti-rust oil to both stationary and moving parts to prevent rusting.

Storage Requirements: Stores molds tightly closed to prevent dust from entering cavities.

VIII. Application Scenarios

1. Bathroom Field

Household Bathroom: Used for pipe connections in showerheads, faucets, toilets, and other bathroom products.

Commercial Bathroom: Bathroom pipeline systems in hotels, guesthouses, public restrooms, and other venues.

2. Industrial Field

Fluid Transportation: Used for pipe connections in industrial equipment cooling systems, hydraulic systems, pneumatic systems.

Chemical Industry: Used for chemical pipeline system connections, offering corrosion resistance and high-pressure tolerance.

3. Municipal Engineering

Water Supply and Drainage Systems: Used for municipal water supply and drainage pipeline connections, with corrosion resistance and long service life.

Fire Protection Systems: Used for fire protection pipeline system connections, with high-pressure resistance and safety reliability.

The 90-degree water inlet fitting mold achieves high-quality, high-efficiency production goals through precision mold design, advanced equipment configuration, and scientific process control. With 10 years of technical accumulation and rich industry experience, Yige Molds ensures products possess excellent dimensional accuracy, stable mechanical performance, and good appearance quality through professional injection molding processes, providing customers with reliable 90-degree water inlet fitting product solutions. Through continuous technological innovation and service optimization, Yige Molds will continue dedicating itself to providing customers with higher-quality products and services, jointly promoting the development of the pipeline connection industry.