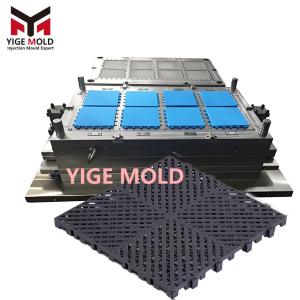

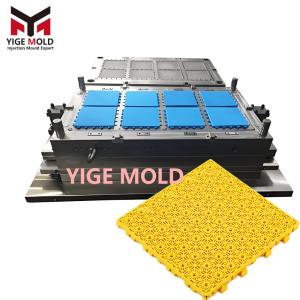

Table plastic mold manufacturing

Plastic Table Mold Manufacturing: A Precision Engineering Process from Design to Mass Production

Plastic Table Mold Manufacturing: A Precision Engineering Process from Design to Mass Production

Plastic table molds are quintessential examples of modern injection molding, where their manufacturing quality directly determines a product's market competitiveness. An excellent mold must not only accurately replicate design details but also maintain stability over hundreds of thousands of cycles, relying on a deep integration of systematic engineering and precision manufacturing.

Part 1: Core Considerations in Mold Design

Structural Analysis and Optimization

The design of a plastic table mold begins with product feasibility analysis. Designers first evaluate fundamental elements such as draft angles (typically no less than 1°), wall thickness uniformity (recommended 2.5-3mm), and rib layout (thickness about 60% of the main wall). For large planar components like table tops, mold flow analysis software is essential to predict the melt flow path and rationally position gate locations. Common solutions like fan gates or multi-point hot runner systems ensure uniform plastic filling and prevent weld lines from appearing in visible areas.

Innovative Cooling System Design

Cooling efficiency dictates production cycles and product quality. Advanced plastic table molds employ conformal cooling technology. Water channels manufactured via 3D printing or special machining processes maintain a constant distance from the cavity surface, reducing cooling time by 25-40%. For traditionally machined channels, a combination of "parallel + series" layouts with turbulence enhancers maximizes heat exchange efficiency.

Venting and Ejection Systems

Air trapped in large surfaces like tabletops must be vented through carefully designed vents (depth 0.015-0.03mm) to prevent burn marks. Ejection systems often use a "gas-assisted + mechanical" combined approach: high-pressure nitrogen is first introduced to slightly separate the product from the cavity over large areas, followed by a平稳 ejection via pin arrays to avoid ejection marks or warping.

Part 2: Material Science and Steel Selection

Graded Application of Mold Steels

-

Core molding components: Use ESR remelted steels like H13 or S136, hardened to HRC 48-52, ensuring long-term wear resistance.

-

Sliders and lifters: Employ high-toughness materials like FDAC, with surface treatments such as titanium-based coatings.

-

Plates and mold bases: Use pre-hardened steels like P20 or high-quality domestic 45# steel to guarantee overall rigidity.

Specialized Surface Treatment Technologies

Different surface requirements call for tailored solutions:

-

Mirror finishes: Employ diamond paste polishing in stages up to #12000 grit.

-

Textured surfaces: Create leather, wood grain, etc., via photochemical etching, with depths of 0.1-0.3mm.

-

Functional coatings: Apply DLC (Diamond-Like Carbon) coatings to high-wear areas, reducing the friction coefficient to below 0.1.

Part 3: Precision Manufacturing Process Flow

Five-Axis Machining Technology

Modern mold manufacturing follows a three-stage process: roughing, semi-finishing, and finishing. Large cavities are first roughed by heavy-duty gantry mills, leaving a 2mm allowance. Five-axis machining centers perform 3D surface finishing with precision up to ±0.015mm. Micro-features and corner clearing use high-speed milling (spindle speeds over 30,000 rpm), achieving surface roughness below Ra 0.4μm.

Innovative Applications of EDM

Precise textures and deep slot structures are completed via CNC Electrical Discharge Machining (EDM). Powder-mixed machining technology, which adds silicon micropowder to the dielectric fluid, improves machined surface roughness to Ra 0.1μm, reducing subsequent polishing time by 60%. For fine textures, nano-scale electrodes enable micro-EDM with a resolution of 0.005mm.

Assembly and Debugging Standards

Mold assembly follows a "three-step inspection method": component-level inspection (using CMM), subsystem testing (verifying cooling/ejection/core-pull functions), and final mold acceptance (24-hour continuous testing on a standard injection molding machine). Clearances for critical mating surfaces are controlled within 0.01-0.02mm. Slider movements employ linear guideways for guidance, with repeat positioning accuracy of ±0.005mm.

Part 4: Mass Production Stability Control System

Intelligent Monitoring Systems

IoT sensors embedded in production molds monitor in real-time:

-

Cavity pressure distribution (8-16 measurement points)

-

Temperature gradient changes (recorded per cycle)

-

Ejection system load curves

Data is analyzed via edge computing to predict anomalies and enable predictive maintenance.

Quick Mold Change Solutions

Standardized interface designs enable full mold changes within 45 minutes:

-

Hydraulic quick-connect couplings (for cooling channels)

-

Integrated electrical modules (for hot runners/sensors)

-

Mechanical positioning systems (zero-point repeatability ±0.002mm)

Maintenance Protocols

A graded maintenance schedule based on usage cycles is established:

-

Every 5,000 cycles: Cleaning, inspection of vent channels

-

Every 30,000 cycles: Comprehensive disassembly, replacement of wear parts

-

Every 100,000 cycles: Factory refurbishment to restore original精度

Quality Control Gateways

Seven key quality gates are established:

-

Design Review (DFM report)

-

Incoming Steel Inspection (Ultrasonic testing)

-

Stress Relief after Rough Machining

-

Full Dimensional Inspection after Finishing

-

Trial Sample Validation (Dimensions/Appearance/Assembly)

-

Pilot Production Confirmation

-

Mass Production Stability Test (CPK ≥ 1.33)