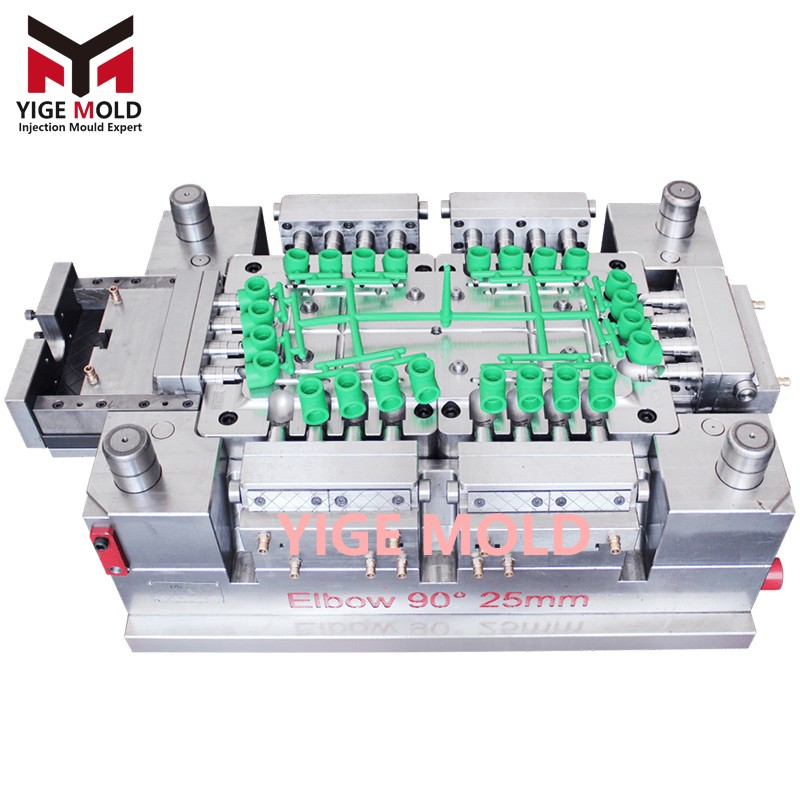

PPR elbow mold

PPR Elbow Mold: Yige Precision, Defining Fluid Connection Reliability

PPR Elbow Mold: Yige Precision, Defining Fluid Connection Reliability

In modern hot and cold water pipeline systems for buildings, PPR elbows are the core precision components that enable changes in fluid direction. Their exceptional long-term static hydraulic strength, perfect thermal fusion connection performance, and design service life exceeding 50 years have their physical origins at the very first stage of injection molding—the PPR elbow mold. Yige Mold deeply understands the engineering value of this critical juncture. We regard it as a system solution that integrates high-precision mechanical design with polymer material science, committed to providing the world's most reliable fluid connection foundation through innovative mold technology.

I. Technical Solutions for Demanding Working Conditions: The Design Philosophy of Yige Mold

PPR elbows must maintain absolute sealing and structural integrity under decades of high temperature, high pressure, and water hammer impact. The design philosophy of Yige Mold is that every detail of the mold must directly respond to the ultimate performance requirements of the end user.

-

Counteracting Material Characteristics to Achieve Absolute Dimensional Stability:

PPR (polypropylene random copolymer) material has significant shrinkage and is temperature-sensitive. Yige Mold uses precise shrinkage compensation based on a material database and full-domain thermal balance simulation to proactively offset deformation caused by material shrinkage and uneven cooling during the mold design stage. We ensure that every elbow produced maintains socket inner diameter, roundness, and end-face perpendicularity tolerances consistently controlled at the industry-leading level of ±0.05mm, laying the geometric foundation for stress-free, leak-free thermal fusion connections.

-

Reinforcing Structural Weak Points to Eliminate Weld Line Hidden Dangers:

The fusion line at the inner corner of the elbow is a potential structural weakness. Yige Mold utilizes 3D mold flow analysis technology to precisely simulate the melt confluence process within the cavity. By optimizing hot runner valve timing and multi-stage injection pressure curves, we fundamentally guide the formation of the fusion line into non-primary stress areas and make it disperse and strengthen, thereby ensuring that the elbow's long-term static hydraulic strength (especially pressure resistance at high temperatures) fully meets or even exceeds international standard requirements such as DIN 8077/8078 and ISO 15874.

-

Addressing High-Efficiency Production and Extreme Lifecycle Challenges:

PPR elbows are typical high-volume, high-consumption standard parts. Yige Mold adopts high-cavitation, valve-gated hot runner systems to maximize production efficiency while ensuring the quality of individual cavities. Core molding components are made from special corrosion-resistant stainless steel or high-hardness tool steel and coated with a nanoscale composite coating to withstand long-term wear and corrosion from additives like glass fibers and colorants in the PPR raw material. The mold design life exceeds 1.5 million cycles, providing customers with unparalleled single-part cost advantages.

II. Core Technology Analysis: Yige Mold's Precision Manufacturing System

A PPR elbow mold manufactured by Yige Mold is a concrete embodiment of its systematic engineering capabilities:

1. Science-First Digital Design:

Design begins with rigorous scientific simulation. The Yige Mold engineering team uses advanced CAE software to complete full-process simulations of filling, pressure holding, cooling, and warpage in a virtual environment. This enables us to predict and resolve potential issues like air traps, short shots, sink marks, and deformation before machining, achieving "first-trial success" and significantly shortening the customer's product development cycle.

2. Extremely Uniform Thermal Management and Cooling:

Cooling variation caused by uneven elbow wall thickness is a primary cause of warpage. Yige Mold applies independently controlled zoned cooling technology and conformal cooling channel design. In thick-wall areas of the elbow (e.g., socket ends), cooling circuits are intensified; in thin-wall areas (e.g., curved surfaces), water flow rate and temperature are optimized, achieving dynamic uniformity in mold temperature. This ensures ultimate product dimensional stability and the shortest possible molding cycle.

3. Precision Structure Ensuring Long-Term Stability:

-

Stress-Free Guiding and Ejection: Utilizes high-precision, self-lubricating guide pillar assemblies and a multi-point balanced ejection system to ensure no degradation in movement precision after millions of opening and closing cycles, enabling smooth, deformation-free ejection.

-

Active Venting and Corrosion Prevention: A multi-stage vacuum venting system is installed in the last areas of the cavity to be filled by the melt, thoroughly eliminating the risk of burns. All water line connections use stainless steel materials, and internal pipelines undergo anti-electrochemical corrosion treatment to prevent reduced cooling efficiency due to scale and rust formation.

4. Intelligent Interfaces for Industry 4.0:

The mold is with standardized status monitoring interfaces, allowing for easy integration of pressure and temperature sensors. This provides the hardware foundation for customers to achieve digital monitoring of the production process and predictive maintenance, assisting customers in building intelligent, transparent factories.

III. Value Extension: From Mold to Reliable Commitment

Choosing the PPR elbow mold solution provided by Yige Mold means customers gain not just a production tool, but an entire value assurance system:

-

Creating Direct Competitiveness for Customers: Extreme dimensional accuracy gives customers' products an excellent assembly experience and market reputation; Exceptionally high production stability and mold life directly translate into lower overall production costs and stronger delivery assurance capabilities.

-

Injecting a Gene of Reliability into the End System: Every elbow produced by a precision mold is the cornerstone for the safe, durable, and maintenance-free operation of the entire pipeline system. Yige Mold, through control at the source, contributes lasting peace of mind to the hidden infrastructure of countless households.

Conclusion

In the field of PPR piping systems, which concerns safety and longevity, every elbow carries a trust. Yige Mold is deeply aware of this responsibility. We build each PPR elbow mold with rigorous engineering logic, forward-looking manufacturing technology, and relentless pursuit of quality. We believe true reliability stems from an obsession with precision at the source. Yige Mold defines connection safety through precision manufacturing, becoming a trusted strategic partner for global pipeline manufacturers.