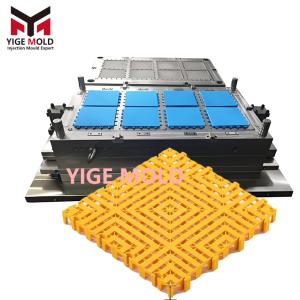

Plastic Cutting Board Mold

Yige Mold is specially designed for food-grade plastics such as PP, PE, and TPR to create plastic cutting boards.

Yige Mold uses high-quality 718h mold steel, and the mold cavities are polished to a mirror finish with a surface roughness of Ra ≤ 0.02 μm. This ensures that the finished cutting board has a smooth surface without burrs, meeting food contact safety standards. It also enhances the wear resistance and corrosion resistance of the mold, with a service life of over 500,000 mold cycles. To meet the needs of preventing slipping and easy cleaning for cutting boards, the mold cavities are precisely engraved with anti-slip textures and drainage grooves, with the texture depth controlled at 0.3-0.5 mm. This ensures an anti-slip effect while avoiding the accumulation of dirt. Additionally, a hanging hole forming structure is reserved to meet the user's storage needs.

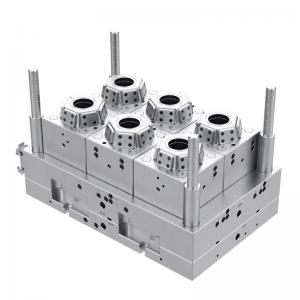

In terms of structural design, Yige Mold adopts a two-piece or three-piece mold structure, combined with a hot runner system, to achieve uniform filling of the molten material, reducing defects such as creasing and bubbles in the cutting board. The molding cycle is only 25-40 seconds, significantly improving production efficiency. The guide pins and guide sleeves are precisely matched, with a positioning accuracy of ±0.005 mm, ensuring smooth mold opening and closing, and maintaining consistent cutting board dimensions, with a tolerance of ±0.2 mm. Moreover, the mold is equipped with an optimized cooling water system, which is designed based on the thickness and shape of the cutting board to layout the flow channels efficiently, quickly removing the formed heat and shortening the cooling time. At the same time, it avoids product deformation.

From small household square cutting boards (20×30 cm) to large commercial circular cutting boards (diameter 50 cm), Yige Mold fully complies with the ISO9001 quality system and food contact mold safety standards. All components in contact with the molten material meet FDA certification requirements, ensuring that the produced cutting boards are non-toxic, odorless, safe, and environmentally friendly. They are widely used in home kitchens, catering institutions, food processing plants, and other scenarios, making them an ideal choice for improving the quality and production efficiency of cutting boards.