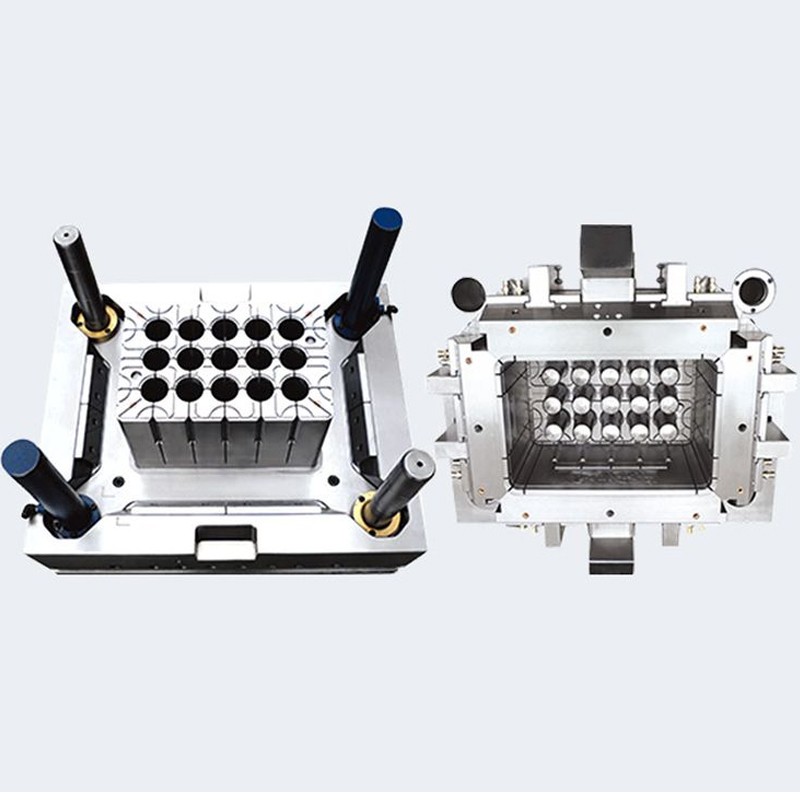

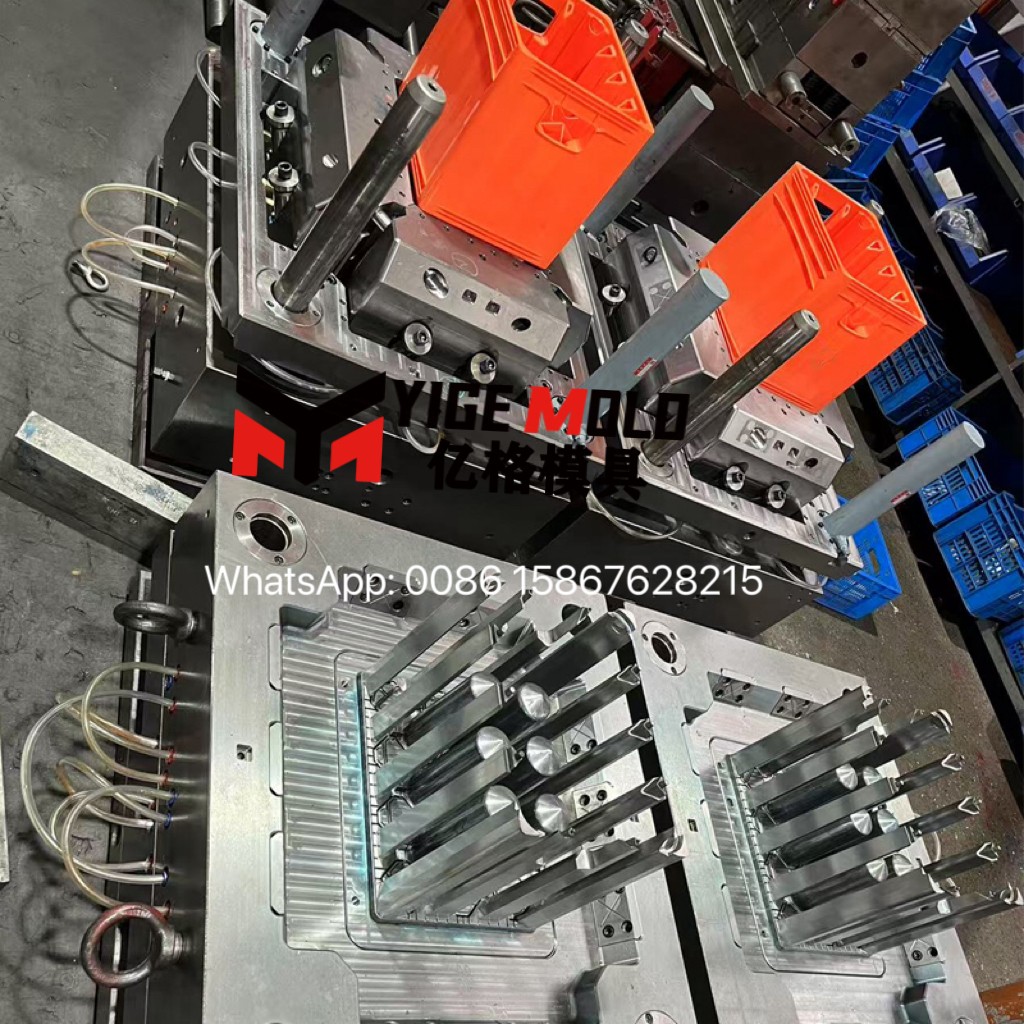

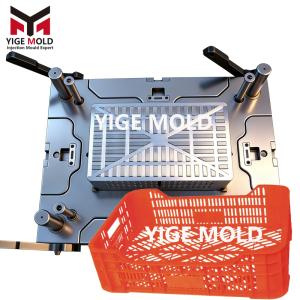

Coca Cola Bottle Crate Mould

China’s Leading Bottle Crate Mould Maker: Precision Engineering for Coca-Cola & Global Beverage Industries

Yige Mold, China top crate mould maker, coca cola bottle crate mould manufacturer, bottle crate mould factory, we made more than 80 sets of various crate moulds per year, with more than 15 years coca cola crate bottle mould making experience for beverage industry, we offer high precision engineering, OEM/ODM solutions, fast delivery, competitive mould price!

In the competitive beverage industry, durable and efficient plastic bottle crates are essential for logistics and branding. As a top crate mold maker in China, we specialize in designing and manufacturing high-performance custom plastic crate moulds tailored for global giants like Coca-Cola and other beverage manufacturers. we exclusively use internationally certified mould steels, including:

1. Premium Mould Steel: The Core of Long-Lasting Performance

• H13 Hot Work Mould Steel: Renowned for its high-temperature resistance (up to 600°C) and exceptional hardness (HRC48-54), H13 is ideal for mould components subjected to repeated stress during injection molding. This steel ensures our moulds withstand over 1 million cycles—a critical requirement for high-volume producers like Coca-Cola.

• S136 Stainless Mould Steel: Used in cavity and core components, S136 offers superior corrosion resistance, vital for environments with frequent sanitization or exposure to moisture. the mirror-polishing capability ensures smooth crate surfaces, minimizing product sticking and enhancing demolding efficiency.

2. Advanced Hot Runner Technology: Precision Melt Control for Efficiency

Yudo hot runner or Other China brand high quality hot runner system as customer required.

• Multi-Zone Temperature Control: Our moulds feature modular hot runner manifolds with independent heating zones, allowing precise regulation of melt temperature (±1°C tolerance). This ensures uniform plastic flow across all cavities, critical for producing crates with consistent wall thickness (e.g., 3-5mm for standard beverage crates).

• Valve-Gated Systems: For large-format crates, we employ valve-gated hot runners to eliminate surface marks at the gate location, a common aesthetic concern for brands like Coca-Cola. This technology also reduces pressure loss, enabling faster fill times and lower clamping forces.

• Sustainability Edge: By recycling 100% of runner material (eliminating cold runner waste), our hot runner solutions help clients reduce plastic consumption by up to 25%, aligning with global sustainability goals.

3. Optimal Cooling Systems: Optimizing Cycle Times and Part Quality

Yige Mold’s proprietary cooling designs are engineered to balance speed and precision, a critical factor in meeting the beverage industry’s tight production schedules:

• 3D-Path Cooling Channels: Using advanced CFD (computational fluid dynamics) simulations, we design spiral or conformal cooling channels that wrap around core components, reducing cooling time by 20-30% compared to traditional straight channels. For example, a 4x6 cavity mould for 24-bottle coca cola crates can achieve a full cycle time of <45 seconds.

• High-Pressure Leak Testing: Every cooling circuit undergoes 100 bar pressure testing to ensure leak-proof performance, preventing water intrusion that could lead to rust or mould degradation.

• Warpage Mitigation: By maintaining a ±2°C temperature gradient across the mould surface, our cooling systems minimize thermal stress, resulting in crates with dimensional accuracy within ±0.15mm—essential for seamless stacking and conveyor belt compatibility.

4. Custom Mould Design for Brand-Specific Requirements

Yige Mold’s engineering team collaborates closely with clients to deliver bespoke solutions:

- Logo and Texture Integration: Precision etching for brand logos and anti-slip textures.

- Multi-Material Compatibility: Molds optimized for PP, HDPE, and recycled blends.

- Ergonomic Designs: Lightweight crates with reinforced handles for easy handling.

5. Quality Assurance: Engineering Excellence from Concept to Completion

Every Yige Mold product undergoes a rigorous validation process:

• Mould Flow Analysis (MFA): Using Moldflow software, we simulate filling, packing, and cooling phases to predict weld lines, air traps, and shrinkage, refining designs before tooling begins.

• 3D Scanning and CMM Inspection: Post-manufacturing, every mould is inspected with Zeiss coordinate measuring machines to ensure 99.5% conformity with CAD models.

From initial design to post-installation maintenance, Yige Mold offer full life cycle support, including 24/7 technical assistance. when you require a Coca-Cola bottle crate mould or a customized solution for craft beverages, we combines technical expertise with a commitment to delivering moulds that enhance productivity and brand excellence. Contact us today to discuss how our advanced engineering can elevate your production line.

Email: quotation@yigemold.com

Whatsapp: 0086 158 6762 8215

Looking forward to start cooperation with you!