Plastic Flower Pot Mold

Plastic Flower Pot Molds: Core Technology for Garden Product Manufacturing

Plastic flower pot molds are specialized injection molding tools designed for producing various plastic flower pots, planters, and planting containers. As key equipment in the garden product manufacturing industry, they directly determine the shape, quality, functionality, and production efficiency of flower pot products.

Core Technical Features

Precision Molding Process

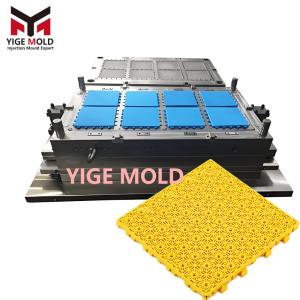

Plastic flower pot molds utilize injection molding technology, where heated and melted plastic materials (such as PP, ABS, PE, etc.) are injected into the mold cavity under high pressure, followed by cooling and solidification to form the finished flower pot. Yige Mold employs an optimized design for the cyclic process in this technology, ensuring stable mass production. To enhance production efficiency, Yige Mold designs multi-cavity flower pot mold structures that support configurations such as 1x2, 1x4, and more complex multi-cavity setups.

Advanced Material Selection

The choice of mold material directly impacts the mold's service life and product quality. Yige Mold maintains strict standards in material selection, commonly using mold steels such as P20, 718, and H13. P20 pre-hardened plastic mold steel is suitable for long-term production of high-quality plastic molds; 718 mold steel offers enhanced hardenability and superior performance, making it ideal for creating large-sized, high-end plastic mold components; H13 hot work mold steel undergoes vacuum quenching before processing to ensure hardness requirements are met.

Precision Structural Design

The structural design of flower pot molds includes critical components such as the gating system, cooling system, venting system, and ejection system. Yige Mold thoroughly considers product characteristics during the design phase, with gate positioning based on professional mold flow analysis to ensure optimal part forming performance and molding quality. Proper gate placement at the thickest section of the part avoids issues like jetting and flow marks. Simultaneously, Yige Mold's optimized design ensures the shortest plastic flow path and minimal flow direction changes, facilitating the expulsion of gases from the cavity.

Product Types and Functional Features

Yige Mold produces molds for a variety of flower pot products, including:

Standard Flower Pots: Conventional shapes such as round, square, and oval, suitable for home gardening.

Gallon Pots: Standard-sized planting containers, commonly used for seedling cultivation and flower production.

Root Control Pots: Containers with air-pruning functionality to promote healthy root growth.

Wall-Mounted Pots: Pots that can be hung on walls or railings, saving space.

Self-Watering Pots: Pots with a built-in water reservoir at the bottom for automatic plant hydration.

Modular Pots: Multi-functional pots that can be assembled and combined, ideal for balcony and courtyard decoration.

Professional Manufacturing Advantages

Yige Mold possesses several professional advantages in the field of plastic flower pot mold manufacturing:

Manufacturing Precision Assurance

Utilizing advanced CNC machining equipment and precision inspection instruments, Yige Mold ensures that mold dimensional tolerances are controlled within ±0.05mm. Comprehensive quality control is implemented throughout the machining process, guaranteeing that each mold component meets design standards.

Technological Innovation Application

Yige Mold applies in-mold cutting technology to achieve automatic gate separation in flower pot molds, reducing post-processing steps. Additionally, optimized cooling system layouts are employed to shorten molding cycles and enhance production efficiency.

Customization Services

To meet the diverse needs of different clients, Yige Mold provides comprehensive customization services. From product design and mold development to trial production and mass manufacturing, Yige Mold's professional team offers full-process technical support.

Quality Control System

Yige Mold has established a comprehensive quality control system, including:

Design Verification Phase: Mold structure analysis and flow analysis are conducted using CAD/CAE software to identify and address potential issues early.

Machining and Manufacturing Phase: Strict adherence to machining process standards, with specialized personnel inspecting each processing step to ensure quality.

Trial and Acceptance Phase: After mold completion, multiple trial runs are conducted, with all parameters recorded to ensure the mold meets design requirements.

Choosing Yige Mold ensures full-process professional support from design to manufacturing, guaranteeing stable product quality and high production efficiency for flower pot molds, thereby creating greater market value for enterprises.