Plastic Flower Pot Injection Mold

Plastic Flower Pot Injection Mold: Specialized Tooling for Horticultural Container Production

A plastic flower pot injection mold represents a highly specialized category within plastic injection tooling, specifically engineered for manufacturing containers designed for plant cultivation and horticultural applications. Unlike general-purpose molds, these tools incorporate unique design considerations for drainage, soil retention, and plant growth requirements.

Technical Design Distinctions

Specialized Structural Elements

Professional flower pot molds feature integrated drainage hole designs that require precise engineering. These drainage systems prevent waterlogging while maintaining structural integrity during injection molding. The molds typically incorporate:

-

Strategically placed drainage outlets (4-8 holes for standard pots)

-

Reinforced bottom structures for load-bearing capacity

-

Graduated wall thickness for optimal material distribution

-

Textured surfaces that provide both aesthetic appeal and improved root adhesion

Advanced Manufacturing Considerations

The production of horticultural containers demands specific attention to several critical factors:

-

Ventilation Design: Special venting systems prevent air traps in intricate geometries

-

Ejection Mechanism: Customized ejection pins avoid damage to delicate structural features

-

Material Flow Optimization: Balanced runner systems ensure uniform filling of complex shapes

-

Cooling Channel Configuration: Targeted cooling maintains dimensional stability

Material Compatibility & Selection

Optimal Plastic Resins

Plastic flower pot molds are engineered to work with specific horticulture-grade materials:

Polypropylene (PP): Primary choice for its chemical resistance and durability

-

UV-stabilized formulations available for outdoor applications

-

Recyclable variants increasingly used in sustainable manufacturing

-

Temperature resistance from -20°C to 120°C

High-Density Polyethylene (HDPE): Preferred for its impact strength

-

Excellent chemical resistance to fertilizers and pesticides

-

Good flexibility prevents cracking in cold temperatures

-

Suitable for large containers and heavy-duty applications

Biodegradable Composites: Emerging material category

-

PLA-based materials for eco-friendly alternatives

-

Starch-based compounds with improved biodegradability

-

Fiber-reinforced options for enhanced structural performance

Production Efficiency Innovations

Multi-Cavity Advancements

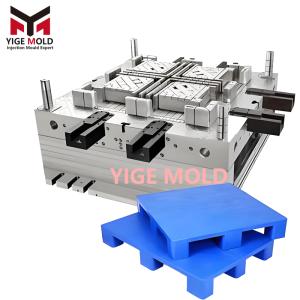

Modern injection molds incorporate sophisticated multi-cavity configurations:

-

Family molds combining various pot sizes

-

Stack mold technology doubling production capacity

-

Quick-change inserts for different drainage patterns

-

Hot runner systems reducing material waste

Cycle Time Optimization

Professional mold designs achieve impressive production speeds:

-

Standard pots (1-5 gallon): 25-45 second cycles

-

Small containers (<1 gallon): 15-30 second cycles

-

Large planters (>5 gallon): 60-90 second cycles

Quality Assurance Standards

Precision Measurement Systems

High-quality flower pot molds implement rigorous quality controls:

-

Coordinate measuring machine (CMM) verification

-

3D scanning for complex geometries

-

Dimensional accuracy within ±0.03mm

-

Surface finish verification with gloss meters

Performance Testing Protocols

Comprehensive testing ensures operational reliability:

-

Injection pressure testing up to 1800 bar

-

Cycle endurance testing (minimum 500,000 cycles)

-

Thermal cycling tests for temperature resistance

-

Stress analysis under maximum fill conditions

Customization Capabilities

Design Adaptability

Professional mold manufacturers like Yige Mold offer extensive customization options:

-

Size variations from 4-inch diameter to 30-inch planters

-

Custom logos and brand markings

-

Specialized textures (wood grain, stone, geometric patterns)

-

Integrated saucers and water reservoirs

-

Stackable/nesting designs for storage and shipping efficiency

Advanced Features Integration

Modern flower pot molds can incorporate sophisticated functions:

-

Self-watering systems with wicking mechanisms

-

Smart drainage systems with removable plugs

-

Integrated handles and carrying features

-

Modular designs for vertical gardening applications

Environmental Sustainability Features

Eco-Conscious Design Elements

Contemporary molds address environmental concerns through:

-

Material reduction through optimized wall thickness

-

Recycled material compatibility

-

Energy-efficient heating and cooling systems

-

Designs facilitating end-of-life disassembly

Production Efficiency Benefits

Advanced mold engineering contributes to sustainability through:

-

Reduced energy consumption per part

-

Minimal material waste (typically <2%)

-

Long service life with proper maintenance

-

Compatibility with bioplastic materials

Industry-Specific Applications

Commercial Horticulture

-

Production-line pots for wholesale nurseries

-

Propagation trays and seedling containers

-

Specialized containers for hydroponic systems

Retail Consumer Products

-

Decorative pots for home gardening

-

Seasonal planting containers

-

Designer collections with premium finishes

Landscape Architecture

-

Large-scale planters for urban installations

-

Custom shapes for architectural integration

-

Durable containers for public spaces

The precision engineering and specialized design of plastic flower pot injection molds directly impact product quality, production efficiency, and environmental sustainability in the horticultural container industry. Yige Mold provides comprehensive mold manufacturing solutions with demonstrated expertise in horticultural applications and proven capabilities in complex mold manufacturing.