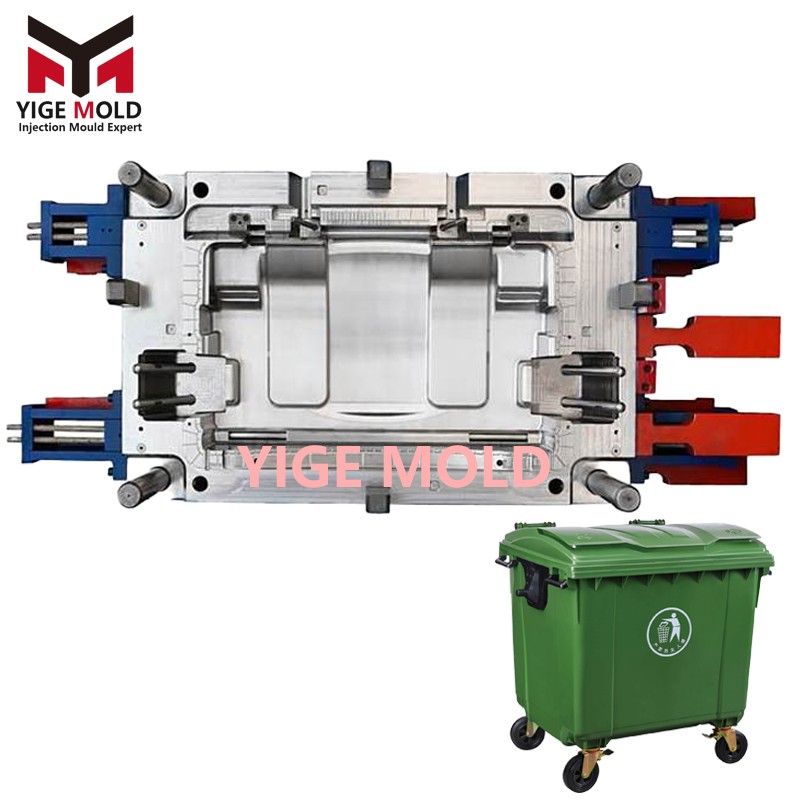

240L Industrial Plastic Garbage Bin Injection Mold

240L Industrial Plastic Garbage Bin Injection Mold - Yige Mold Manufacturing

Product Features

The 240L Industrial Plastic Garbage Bin Injection Mold manufactured by Yige Mold is designed for large-scale waste collection needs. Utilizing a single-cavity molding layout, it ensures a stable product structure, making it suitable for municipal sanitation, industrial zones, and commercial facilities.

Technical Specifications

|

Parameter |

Specification |

|---|---|

|

Mold Type |

Hot Runner Injection Mold |

|

Cavity Layout |

1-out-1 single cavity |

|

Mold Material |

P20/718H pre-hardened mold steel |

|

Cycle Time |

8-12 seconds/mold |

|

Daily Capacity |

700-800 pieces |

|

Mold Life |

Over 1.5 million cycles |

|

Suitable Injection Machine |

1800-2500 tons |

|

Delivery Period |

35-45 days |

Mold Design Features

Hot Runner System: Utilizes valve-gate hot runner technology to ensure balanced filling and reduce runner waste.

Cooling System: Multi-circuit cooling channel design improves cooling efficiency and shortens cycle time.

Ejection Mechanism: Combines ejector pins and hydraulic slides for smooth demolding of large-sized products.

Exhaust Structure: Step-type exhaust design prevents gas traps.

Product Performance

-

Compatible with high-density polyethylene (HDPE) material

-

Bin wall thickness ≥5mm, ensuring structural stability

-

Suitable for environments ranging from -30°C to 65°C

-

Compliant with relevant industry standards

Services and Support

Design Customization: Provides product structure analysis and mold optimization solutions, supporting personalized functional designs.

Trial Run Verification: Conducts multiple trial runs before delivery to ensure mass production stability.

Response Support: Offers timely technical consultation and on-site service.

Quality Assurance: Provides a warranty period and long-term maintenance services.

Application Scenarios

-

Municipal Sanitation: Streets, parks, public areas

-

Industrial Zones: Factories, logistics parks

-

Commercial Facilities: Shopping malls, hotels, office buildings

-

Community Services: Residential areas, schools, hospitals

Cooperation Process

Requirement Communication → Solution Design → Structure Confirmation → Mold Manufacturing → Factory Trial Run → Mass Production → After-sales Support