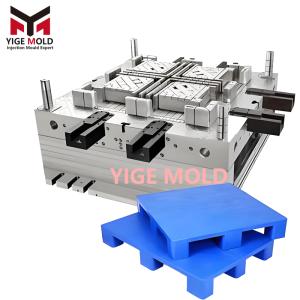

Dairy crate mold

Dairy Crate Mold: The Precision Cornerstone of Efficient Logistics and Circular Economy

Dairy Crate Mold: The Precision Cornerstone of Efficient Logistics and Circular Economy

In today's globalized dairy supply chain, every drop of milk undergoes a complex yet highly efficient journey from pasture to table. Supporting this journey, beyond advanced cold chain technology, is a seemingly simple yet critically important component—the plastic dairy crate. Behind every sturdy, uniform, and durable crate lies its origin: the dairy crate mold. As a professional mold manufacturer, Yige Mold understands this deeply: it is far more than just a metal "mold." It is a high-tech product that integrates materials science, precision engineering, and stringent quality control—a precision cornerstone of modern industrial packaging and logistics systems.

I. More Than Just a Container: The Stringent Requirements for Dairy Crates and the Core Role of the Mold

To understand the importance of the mold, one must first clarify the core requirements of the finished product. A qualified dairy crate is not an ordinary plastic box; it must meet:

-

Extremely High Structural Strength and Stacking Load Capacity: It must be able to stably stack multiple layers high (often 8-10 layers) when fully loaded (typically over 20kg) to maximize storage and transportation space utilization.

-

Exceptional Impact Resistance and Low-Temperature Toughness: It must withstand repeated use in cold chain environments ranging from -25°C to 60°C and resist impact during loading/unloading without cracking.

-

Precise Dimensional Stability: It must seamlessly interface with automated filling lines, sorting robots, conveyor belts, and shelf systems, with tolerances often controlled within ±0.5mm.

-

Hygiene and Easy Cleanability: The surface must be smooth without dead corners, leak-proof, compliant with food contact standards (e.g., FDA, EU 10/2011), and allow for quick washing and sanitization.

-

Ergonomic and Identification Design: Features include ergonomic handholds and clear textures for brand logos, production date codes, recycling symbols, etc.

These stringent performance indicators must all be achieved at once through the design and manufacturing of the mold. Yige Mold believes that the quality of the mold directly determines the lifecycle value, production efficiency, and usage safety of the crate.

II. The Core Practice of Yige Mold: The Essence of Dairy Crate Mold Design and Manufacturing

A top-tier dairy crate mold is the concentrated embodiment of its high value. Leveraging years of industry expertise, Yige Mold consolidates its technical core into the following practices:

1. Reliability-First Structural Design

-

Efficient Runner and Gate System: Yige Mold proficiently employs full hot runner systems, significantly reducing cold slug waste and shortening cycle times. Through precise runner balancing design, it ensures uniform filling and minimized internal stress across all points of the large crate. Gate locations are carefully determined through simulation, often placed in non-critical stress areas of the base to ensure product strength and aesthetics.

-

Optimized Cooling System: The lifeline of mold longevity and production efficiency. Yige Mold is committed to designing high-efficiency conformal cooling channels. Through precision machining, channels are placed as close as possible to the cavity surface, ensuring uniform and rapid cooling throughout the crate's wall thickness. This is key to reducing product warpage, shortening cycle times, and enhancing the mechanical properties of the product.

-

Stable Ejection and Adequate Venting: For large, deep-cavity products, Yige Mold employs multi-point pneumatic-assisted ejection or high-tonnage hydraulic direct ejection systems to ensure smooth, distortion-free demolding. Simultaneously, precise venting slots or venting inserts are placed in areas prone to air traps (like ribs and corners) to fundamentally prevent defects like burn marks and short shots.

-

Robust Parting and Core-Pulling Mechanisms: For features like side handholds and internal locking slots, Yige Mold designs rigid, smooth-operating sliders and lifters, with an emphasis on wear-resistant treatments. This ensures precise positioning even after millions of cycles, preventing flash formation.

2. The Pursuit of Excellence in Materials and Durability

Yige Mold understands that long service life is key to customer cost-effectiveness. Core mold components are made from high-grade pre-hardened mold steel (e.g., imported 718H, 2738H) or hardened high-hardness steel (e.g., H13). Key components like cores and cavities undergo deep nitriding or PVD coating, significantly increasing surface hardness (above 50 HRC) and corrosion resistance. This enables the mold to withstand the long-term production challenges of highly abrasive materials like glass-filled polypropylene (GF-PP), ensuring a stable service life exceeding one million cycles.

3. Digital Verification Ensures First-Time Success

At Yige Mold, digital verification is a standard procedure. Before machining, authoritative mold flow analysis software like Moldflow is used to simulate the entire process of plastic filling, packing, cooling, shrinkage, and warpage. This step predicts and optimizes weld line locations, sink mark risks, cooling efficiency, and potential warpage tendencies in advance. It solidifies the design to an optimal state, greatly enhancing the "first trial success rate" and saving customers valuable time and trial costs.

III. Value Delivery by Yige Mold: Driving Win-Win Outcomes for Customers and the Industry

A high-performance dairy crate mold delivered by Yige Mold creates value throughout the supply chain:

1. For the Product Manufacturer (Our Customer):

-

Maximized Production Efficiency: Stable, high cycle speeds and minimal unplanned downtime translate into predictable, impressive daily output, directly reducing per-unit production costs.

-

Guaranteed Product Quality Consistency: From the first shot to the millionth, every crate produced maintains stable, excellent physical properties and dimensional accuracy, helping customers solidify their market reputation.

-

Optimized Total Cost of Ownership: The extended mold service life and low maintenance requirements significantly reduce the per-crate mold depreciation cost, delivering a high return on investment for customers over many years.

2. Deep Contribution to the Dairy Industry Chain:

-

Enhances Overall Logistics Efficiency: Standardized, high-strength crates produced by precision molds are the physical foundation for automated handling, intelligent warehousing, and unit-load transportation.

-

A Robust Food Safety Barrier: The seamless, smooth crate structure achieved by the mold minimizes the potential for dirt residue and bacterial growth by design, facilitating thorough cleaning and sanitization.