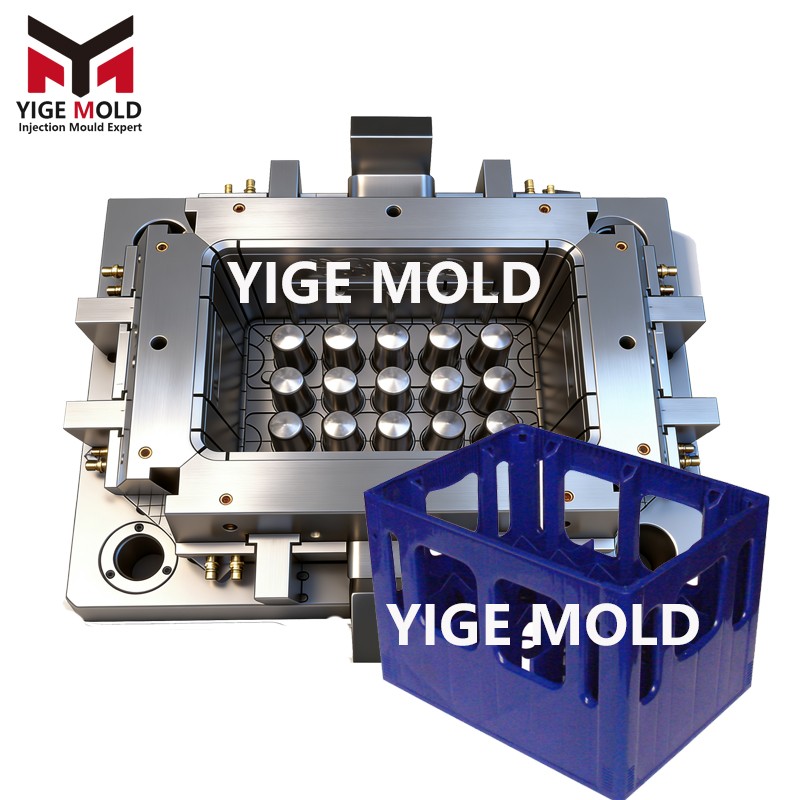

Beverage box mold

Excellent Design, Precision Manufacturing: Yige Beverage Box Mold Solution

Design Philosophy: Integration of Functional Aesthetics and Engineering Innovation

The Yige Molds design team adheres to the core principle of "structural optimization, functionality first," achieving three major breakthroughs in the design of beverage box molds:

Structural Design Optimization

Utilizing Finite Element Analysis (FEA) technology to conduct stress simulations on mold structures, ensuring structural stability under long-term, high-load production. The unique reinforcement rib design increases the load-bearing capacity of beverage boxes by 40%, while optimizing wall thickness distribution to achieve lightweight design without compromising strength.

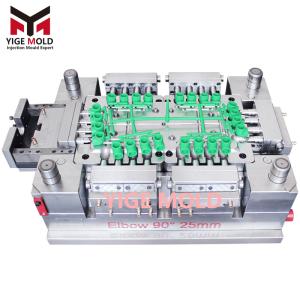

Runner System Innovation

Developed patented fan-shaped runner technology, achieving balanced filling of molten plastic in multi-cavity molds, effectively eliminating weld lines and air pocket defects. The runner system reduces energy consumption by 25% compared to traditional designs, and the injection cycle is shortened by 18%.

Demolding Mechanism Design

Utilizes a hydraulic-mechanical linkage demolding system to achieve smooth demolding in complex curved surfaces and undercut areas. Specially designed angled lift structures ensure damage-free product demolding, with a yield rate of over 99.2%.

Manufacturing Process: Precision Machining and Quality Control System

Digital Manufacturing Workflow

-

CNC Precision Machining: Uses five-axis machining centers to achieve high-precision processing of complex mold cavity surfaces.

-

EDM Machining: Employs mirror EDM technology to handle deep holes and fine structures.

-

Coordinate Grinder Finishing: Ensures mold alignment accuracy within ±0.005mm.

-

Surface Treatment: TiN coating technology extends mold lifespan by 3–5 times.

Quality Monitoring System

-

Full-dimensional inspection with coordinate measuring machines

-

Surface comparison via blue light scanning systems

-

Internal defect detection with ultrasonic flaw detection

-

Dynamic balance testing to verify mold stability

Technological Innovation Highlights

Quick Mold Change System

Integrated hydraulic automatic mold change device reduces mold change time from 4 hours to 25 minutes, significantly improving equipment utilization.

Intelligent Temperature Control Technology

Utilizes multi-point zonal temperature control systems combined with PID intelligent algorithms to achieve mold temperature control with ±0.5°C precision, effectively solving shrinkage and deformation issues.

Modular Design Philosophy

Standard mold bases paired with customized cavity components enable rapid customization while reducing manufacturing costs, shortening delivery times by 30%.

Application Solutions

Tailored solutions for different beverage packaging needs:

-

Carbonated Beverage Boxes: Reinforced structural design for high-pressure environments

-

Juice Packaging Boxes: Food-grade surface treatment compliant with FDA standards

-

Dairy Product Storage Boxes: Antibacterial coating technology meeting hygiene requirements

-

Craft Beer Boxes: Multi-layer co-injection technology for enhanced thermal insulation

Technical Service System

Pre-Production Technical Support

-

Product structural analysis and optimization

-

3D mold solution design

-

Injection molding simulation

-

Cost-benefit analysis

In-Process Manufacturing Services

-

Real-time production progress tracking

-

Video recording of key processes

-

Online quality inspection reports

-

Regular technical communication meetings

After-Sales Support

-

On-site debugging and guidance

-

Operator training

-

Regular maintenance reminders

-

Technical upgrade services

With its outstanding design capabilities and exquisite manufacturing processes, Yige Molds provides professional mold solutions for beverage packaging companies worldwide. From concept design to mass production, we are committed to creating maximum value for our customers, using precision molds to forge quality packaging.

Visit our website for more technical materials, or schedule an appointment for engineers to inspect our production facilities.