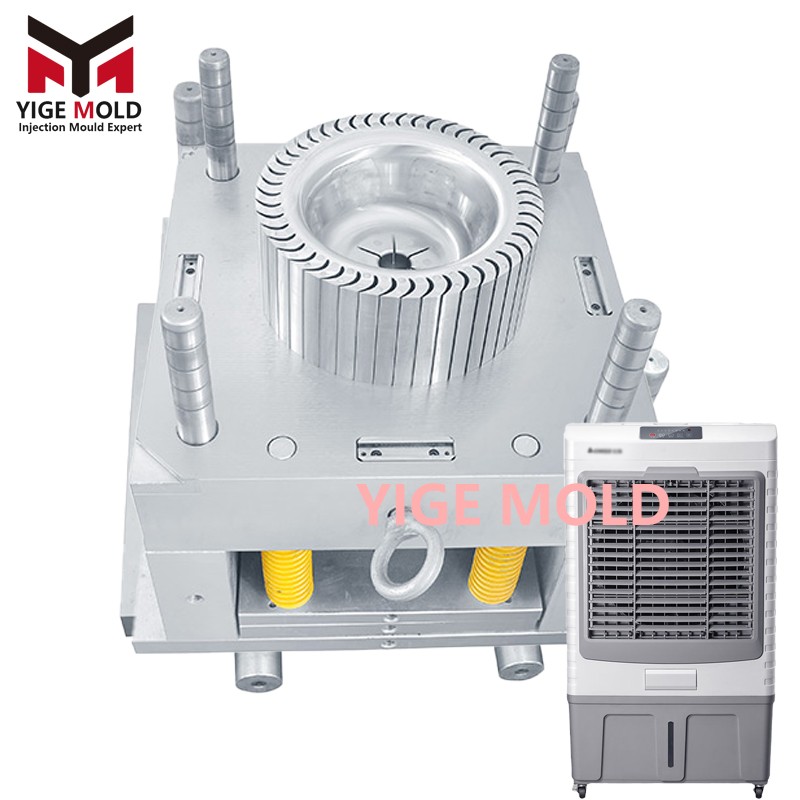

Evaporative Cooler Mold

Evaporative Cooler Mold Introduction - Yige Molds Professional Solution

Evaporative Cooler Mold Introduction - Yige Molds Professional Solution

I. Product Overview

The evaporative cooler mold is professional injection mold equipment from Yige Molds used for manufacturing evaporative cooler housings and components. Evaporative coolers (also known as swamp coolers) are energy-efficient and environmentally friendly devices that utilize the principle of water evaporation for air cooling.

II. Yige Molds Core Design Advantages

1. Precision Structural Design

Yige Molds adopts streamlined cavity structures, optimized through fluid simulation design to ensure uniform plastic distribution during injection, preventing bubbles or defects. The mold's internal structure is meticulously designed to guarantee cooling effectiveness and product performance. Reasonable parting surface design ensures uniform plastic flow during injection, preventing shrinkage marks and other defects.

2. Efficient Cooling System

Yige Molds' cooling system features an optimized circulating water structure, with zoned independent temperature control technology maintaining cavity temperature differences ≤±0.5°C. Cooling circuits use direct circulation design with symmetrical upper and lower mold arrangements, improving cooling uniformity. Pulsating cooling technology improves cooling efficiency by 35%, effectively shortening molding cycles.

3. Premium Material Selection

Yige Molds uses premium mold steels including P20, 718, 2738, S136, NAK80. Core materials employ H13ESR electroslag remelting steel with hardness HRC48-52, improving thermal fatigue life by 40%. Slider components use Japanese Hitachi mold steel SLD-MAGIC, vacuum heat treated to HRC60-62. Hot runner systems use German Yaba high-temperature alloys, long-term withstand 420℃ melt temperature.

III. Yige Molds Technical Advantages

1. Ultra-Precision Processing Technology

Yige Molds utilizes five-axis machining centers for precision processing, with cavity accuracy controlled within ±0.005mm. Key components use slow wire EDM with accuracy reaching ±0.002mm, mirror EDM achieving surface roughness Ra≤0.1μm. Three-coordinate measurement ensures key dimensions CPK≥1.67, guaranteeing precise product dimensions and smooth surfaces.

2. High-Efficiency Production System

Yige Molds employs hot runner technology with scrap rate ≤0.8%, saving 15%-20% energy compared to traditional cold runner technology. Quick mold change system reduces changeover time to ≤15 minutes with automatic centering accuracy ±0.02mm. Servo motor drives reduce energy consumption by 42%, with cooling water recycling rate reaching 95%.

IV. Yige Molds Manufacturing Process

1. Design Process

Yige Molds uses mold flow analysis to predict and eliminate potential defects. Structural simulation ensures mold life ≥1.5 million cycles. Virtual trial molding system reduces actual trial molding times by 60%. Standard mold base library offers 500+ specifications. Intelligent parts library provides 3000+ standard parts with one-click availability. Parametric design reduces similar mold design time by 70%.

2. Precision Manufacturing Process

Yige Molds uses five-axis machining centers with positioning accuracy 0.003mm. Slow wire EDM with accuracy ±0.002mm. Mirror EDM achieving surface finish Ra0.05μm. Surface treatment includes diamond-like carbon coating with hardness HV3000-5000. Nano composite coating reduces friction coefficient to 0.08. PVD gradient coating reduces demolding force by 30%.

V. Yige Molds Service System

1. Technical Consulting Services

Yige Molds provides free design reviews, delivering product DFM (Design for Manufacturing) analysis reports. Material selection recommendations and cost optimization solutions. Estimated mold life and production efficiency analysis. 24-hour online technical support. Emergency problem response within 4 hours. On-site service engineers arriving within 48 hours.

2. Mold Delivery Guarantee

Yige Molds offers standard delivery processes, providing detailed project schedules after contract signing. Weekly progress reports with photos/video updates. Trial sample express delivery with synchronized test reports. Mold acceptance includes 22 inspection items. Trial production continuous 500-cycle stability testing. Complete mold usage and maintenance manual provision.

3. After-sales Service System

Yige Molds provides lifetime maintenance commitment with free lifetime technical consultation for molds. Wearing parts supplied at cost price. Regular free mold health checks. Upgrade and renovation services including mold performance optimization upgrades. Product modification mold renovations. Automation matching solution design.

VI. Technical Support and Training

1. Operation Training Courses

Yige Molds provides mold installation and debugging standard operating procedures. Injection molding process parameter optimization methods. Mold daily maintenance essentials. Common fault diagnosis and troubleshooting.

2. Technical Database

Yige Molds provides complete sets of 3D drawings and 2D engineering drawings. Material property tables and technical data manuals. Injection molding process window recommended parameters. Quality control plans and inspection standards.